Mounting method of visual plug template group device of template trolley plug

A technology of plug formwork and formwork trolley, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc. It can solve problems such as uneven pressure, incomplete concrete pouring, and easy occurrence of voids or air bubbles, so as to reduce voids or air bubbles , Accelerate the construction progress, improve the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

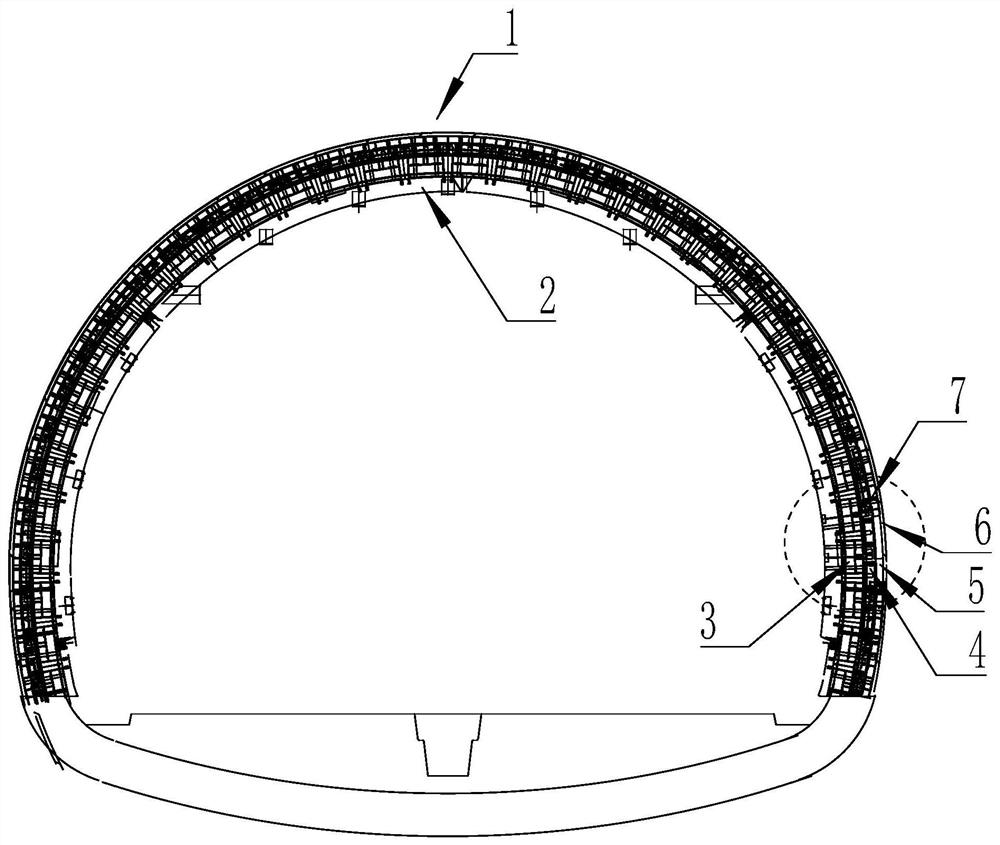

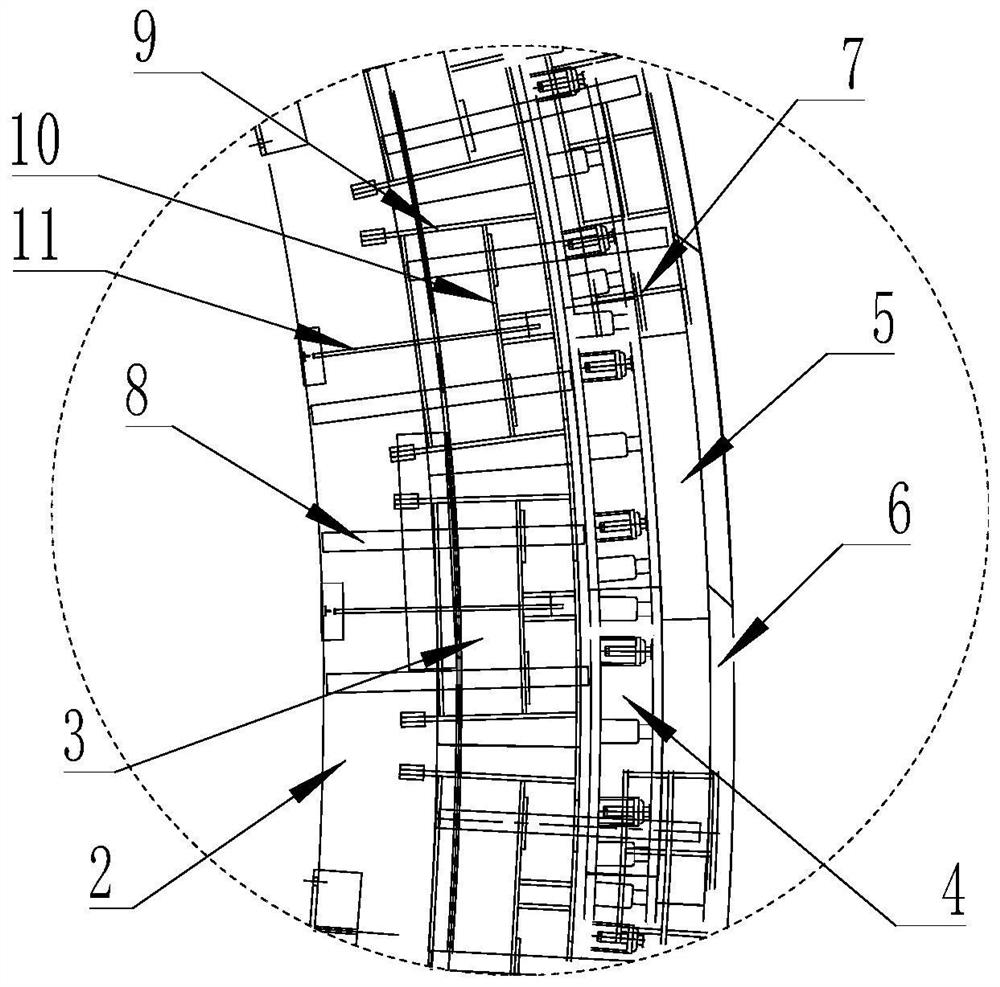

[0032] The top and both sides of formwork trolley 1 are set as arched formwork 2-1, the inner sides of both ends of formwork 2-1 are respectively set as formwork flanges 2, and the outer sides of formwork flanges 2 are respectively set as three sets of plug steel Formwork 3; three sets of plugging steel formwork 3 on the outside of formwork flange 2 are combined to form an arched plugging steel formwork, and the outer sides of the arched plugging steel formwork are respectively set as four-layer telescopic plugging molds. The molds are arranged in turn from the inside to the outside as a buried waterstop 14, a telescopic plug template 4, a plug heightening module 5, and an elastic pad 6. The upper end of the elastic pad 6 corresponds to the arch wall waterstop 13 on the inner wall of the tunnel;

[0033] A pair of steel mold turning frames 9 are arranged between the outer sides of the formwork flange 2 and the plug steel formwork 3 respectively, and Joule 2-2 is set between the...

Embodiment 2

[0040] When the gap between the outside of the first piece of plug steel formwork 3 at one end of formwork trolley 1 and the inner wall of the tunnel is sealed, the telescopic plug formwork 4, the plug heightening module 5, and the elastic cushion block 6 correspond to the plug steel formwork respectively. 3. After the outer edge is manually corrected, the telescopic screw 4-3 is manually rotated, and the telescopic screw 4-3 pushes the telescopic module 4-1, the plug heightening module 5, and the elastic pad 6 to run outwards and the tunnel After the inner wall is contacted, extruded and sealed, the rotation of the telescopic lead screw 4-3 is stopped, and the sealing of the gap outside the first plug steel template 3 is completed.

Embodiment 3

[0042] After the gap sealing between the plug steel formwork 3 and the inner wall of the tunnel is completed, the plug support frame 7 is placed on the outside of the telescopic plug formwork 4 and the plug heightening module 5, and a pair of columns at the outer ends of the double-layer steel form bracket 10 After the frame support post 8 is manually inserted upwards to the outside of the plug support frame 7, a pair of post screw 12 is manually rotated and fixed to a pair of frame support post 8 respectively, and the first plug is completed. Sealing of the gap between the outside of the steel formwork 3 and the inner wall of the tunnel;

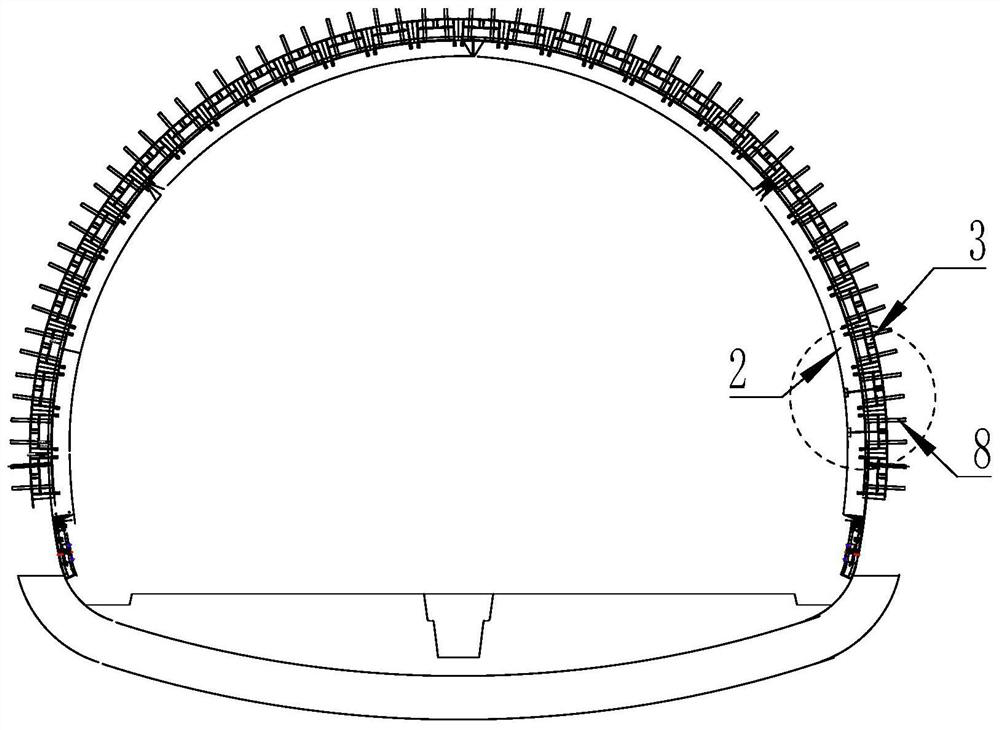

[0043] According to the above operation method, install each piece of plugging steel formwork 3 from one end to the other end of the formwork trolley 1 to the other end to seal the gap between the outside of the tunnel inner wall until all the ends of the formwork trolley 1 are plugged outside the steel formwork 3 After the gap sealing with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com