Sealed type automatic alloying and refining integrated device for magnesium alloy

An automatic alloying and sealing technology, which is applied to lighting and heating equipment, furnace types, furnaces, etc., can solve the problems of laborious replacement of zeolite equipment, environmental pollution, etc., and achieve the goal of improving work safety, reducing environmental pollution, and saving consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

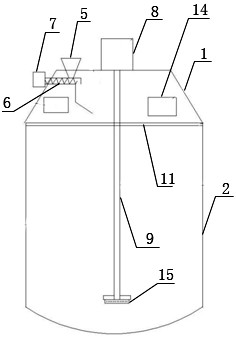

[0027] The present invention will be further described in conjunction with the accompanying drawings.

[0028] The invention is a device integrating sealing, alloying and refining.

[0029] The tightness is that the stirring device, the automatic alloying device and the automatic fluxing device are welded together through the sealing cover 1, and the sealing cover 1 is buckled on the crucible flange, which can realize the fully sealed operation of automatic alloying and refining. The flue gas that produces is connected with environmental protection equipment through air outlet 14.

[0030] The automatic alloying device is to set an alloying window above the sealing cover 1, weld an alloying basket on the alloying window, place the alloy to be added in the alloying basket in advance, and the lower part of the alloying basket contacts the magnesium liquid, and the alloy Slowly move down until melting is complete. The upper part of the melting basket is fully covered, including...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com