Teamcenter-based heterogeneous collaborative design method for automobile factory coating line

A collaborative design and coating line technology, applied in special data processing applications, configuration CAD, geometric CAD, etc., can solve problems such as mixed assembly cannot be realized, achieve the effect of shortening the equipment development cycle and facilitating process monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

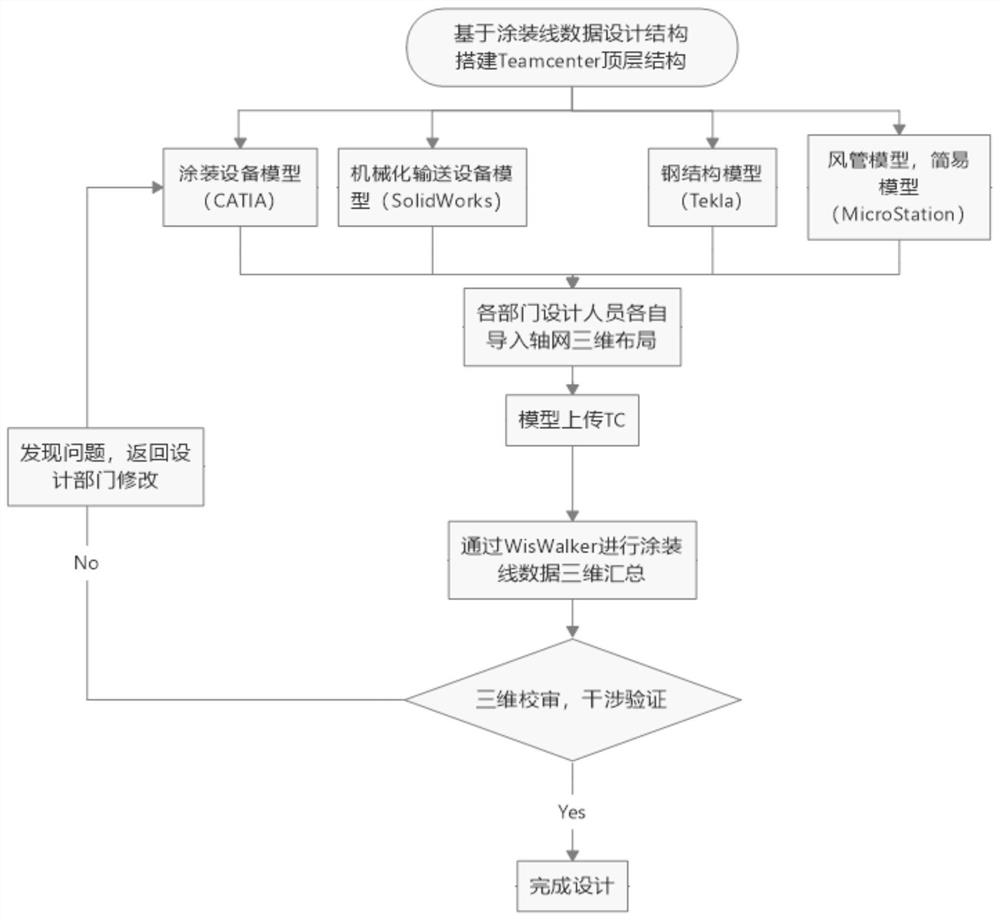

[0023] see figure 1 , the present invention provides a technical solution: a teamcenter-based heterogeneous collaborative design method for an automobile factory painting line, comprising the following steps:

[0024] Step 1. Build a top-level structure tree based on the Teamcenter platform and integrate WisWalker and 3D modeling software. Through its own system characteristics, based on the existing CAD source format files, a grid file in the JT source format that has nothing to do with it can be constructed;

[0025] Step 2. The designer downloads the grid file from the Teamcenter platform, and designs and modifies the grid file based on the visualization of WisWalker;

[0026] Step 3. The designer uploads the design and the modified grid file and stores it under the corresponding node of the top-level structure tree;

[0027] Step 4. Based on the WisWalker integrated in the top-level structure tree, check the interference, add annotations or modify comments on the grid fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com