Insulator surface structure modification method and application

A surface structure and insulator technology, which is applied in the field of surface structure modification of insulators, can solve problems such as easy peeling off of the coating, electric field distortion, etc., and achieve the effect of promoting popularization and application, restraining movement, and remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

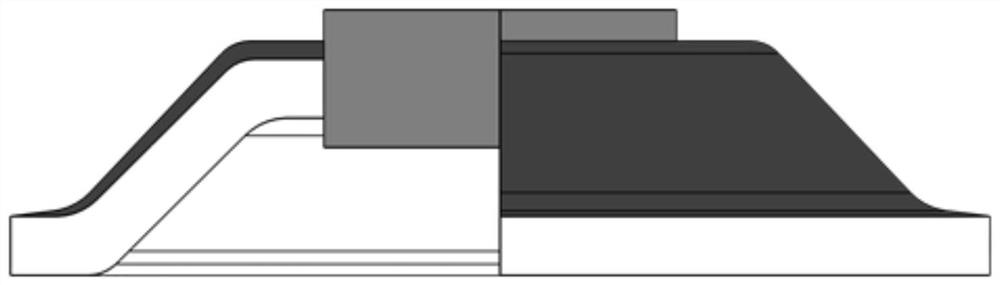

Image

Examples

Embodiment 1

[0022] The specific surface uniform fluorination treatment process of basin type insulators is as follows:

[0023] (1) Before installing the high-voltage DC GIL / GIS pot insulator, place the epoxy resin pot insulator in a vacuum fluorination reactor, and fill the reactor with a mixed gas with a volume ratio of 1:6 fluorine gas and nitrogen gas to react The conditions are: the gas temperature is 10°C, the gas pressure is 0.04Mpa, and the epoxy resin pot insulator is modified for 15 minutes.

[0024] (2) Using the DC GIL / GIS system, analyze the inhibitory effect of the high-conductivity surface-modified pot-type insulator under different operating conditions on its convex surface and metal particles at different positions from the insulator.

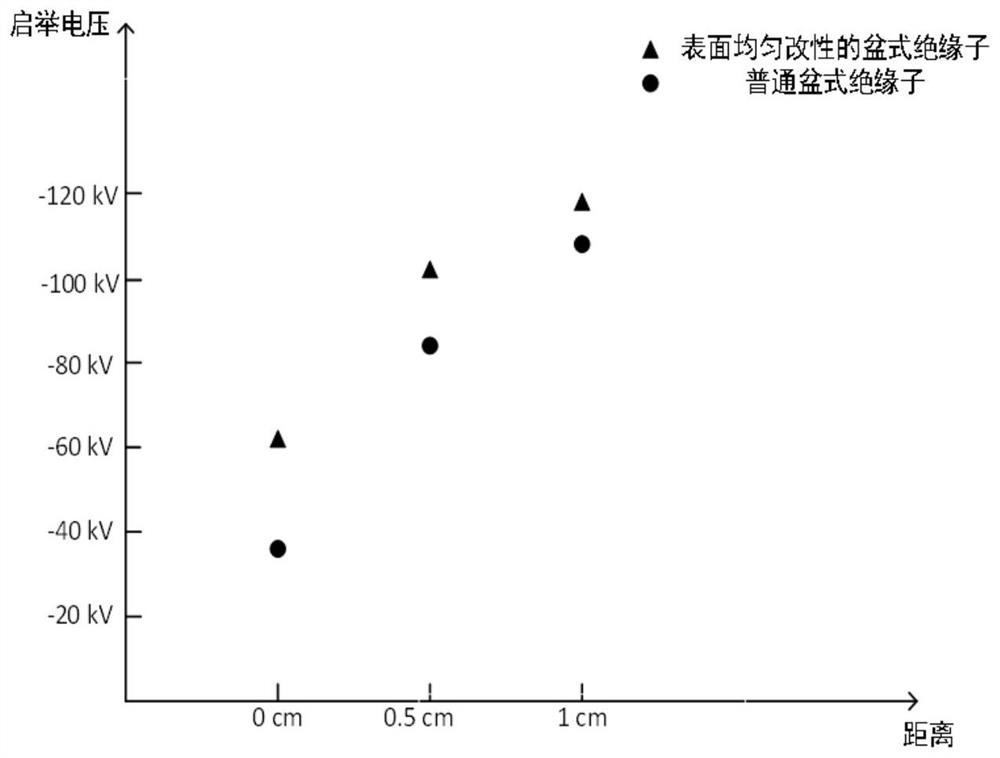

[0025] (3) According to the experimental results, compared with ordinary GIL basin insulators, GIL / GIS basin insulators with modified surface structure have a significant inhibitory effect on the movement of metal particles at different po...

Embodiment 2

[0027] (1) Before installing the high-voltage DC GIL / GIS basin insulator, place the epoxy resin basin insulator in a vacuum fluorination reactor, and fill the reactor with a mixed gas of fluorine and nitrogen at a volume ratio of 1:10 to react The conditions are: the gas temperature is 50°C, the gas pressure is 0.1Mpa, and the epoxy resin pot insulator is subjected to surface structure modification treatment for 30 minutes.

[0028] (2) Using the DC GIL / GIS system, analyze the inhibitory effect of the high-conductivity surface-modified pot-type insulator under different operating conditions on its convex surface and metal particles at different positions from the insulator.

[0029] (3) According to the experimental results, compared with ordinary GIL basin insulators, GIL / GIS basin insulators with modified surface structure have a significant inhibitory effect on the movement of metal particles at different positions, see figure 2 .

Embodiment 3

[0031] (1) Before installing the high-voltage DC GIL / GIS pot insulator, place the epoxy resin pot insulator in a vacuum fluorination reactor, and fill the reactor with a mixed gas of fluorine gas and argon gas at a volume ratio of 1:1. The reaction conditions are: the gas temperature is 50°C, the gas pressure is 0.01Mpa, and the epoxy resin pot insulator is modified for 60 minutes.

[0032] (2) Using the DC GIL / GIS system, analyze the inhibitory effect of the high-conductivity surface-modified pot-type insulator under different operating conditions on its convex surface and metal particles at different positions from the insulator.

[0033] (3) According to the experimental results, compared with ordinary GIL basin insulators, GIL / GIS basin insulators with modified surface structure have a significant inhibitory effect on the movement of metal particles at different positions, see figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com