Common-mode inductor and single-phase robot filter

A technology of common-mode inductors and filters, which is applied in the field of single-phase robot filters and common-mode inductors, can solve the problems of filter component damage, filter installation difficulties, and large filter volume, so as to reduce volume and connect Convenience and quickness, the effect of reducing the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

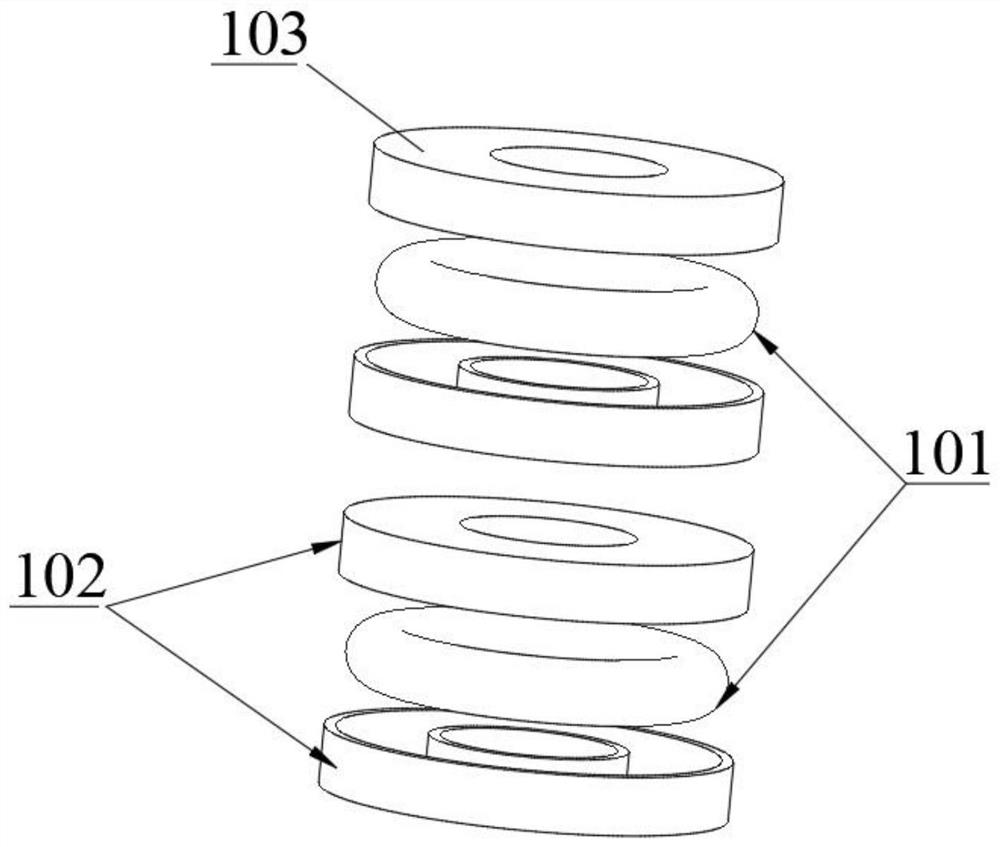

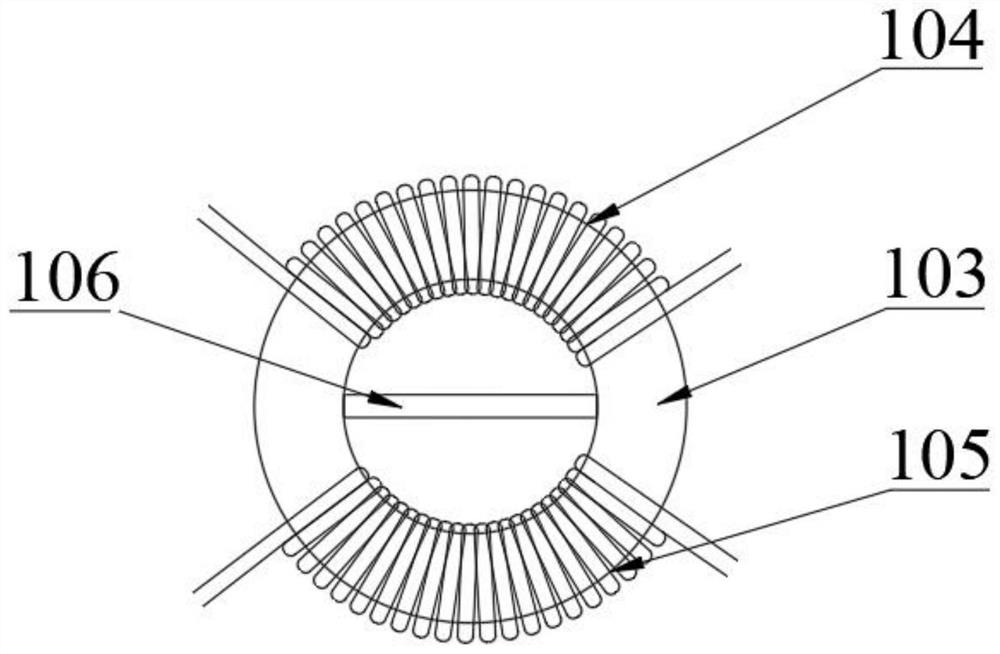

[0025] refer to figure 1 , figure 2 , a common mode inductor proposed by the first embodiment of the present invention, comprising: two magnetic rings 101, a skeleton 102 is arranged outside the magnetic rings, and a plurality of magnetic rings overlap in the axial direction to form a magnetic core 103; one of the magnetic cores A first winding 104 is wound on one side, and a second winding 105 is wound on the other side; an insulating sheet 106 is provided between the first winding and the second winding.

[0026] In this embodiment, the skeleton 102 is composed of two annular shells, and the magnetic ring 102 is accommodated between the two annular shells.

[0027] It should be noted that, in other embodiments of the present invention, the number of magnetic rings is not limited to two, and the number of magnetic rings can be adjusted according to actual needs to achieve the required inductive reactance.

[0028] In the present invention, the common-mode inductor adopts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com