Ceramic with simulated rough stone glaze

A rough and stone technology, applied in the field of simulating rough stone glaze and ceramics using the glaze, can solve the problems of rough touch, roughness and unsatisfactory touch on the glaze surface, achieve strong rough stone hand feel, enhance vision and appearance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

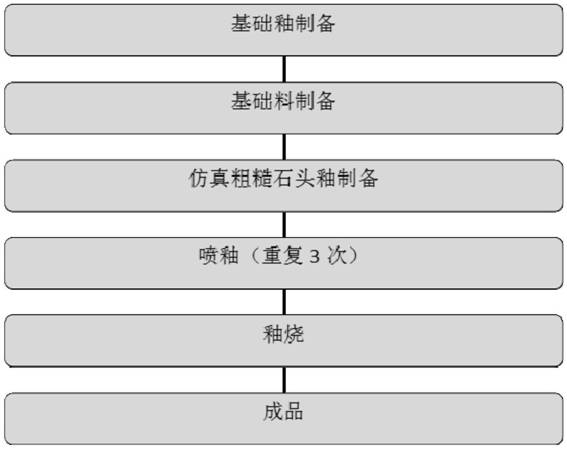

[0020] A method for preparing simulated rough stone-glazed ceramics, comprising the following steps:

[0021] S1. Prepare the basic glaze: take 15 parts of aluminum powder, 30 parts of quartz, 30 parts of potassium feldspar, 10 parts of kaolin, 5 parts of calcium carbonate, and 10 parts of barium carbonate, and mix them evenly to obtain the basic glaze;

[0022] S2. Prepare the base material: take 85-90% of the base glaze prepared in step S1, 10-15% of the black pigment, and 0.05-0.1% of sodium phosphate, and mix evenly;

[0023] S3. Mix the base material prepared in step S2 with water at a ratio of 1:0.6-0.8, put it into a ball mill, grind for 12 hours, and filter to obtain a simulated rough stone glaze.

[0024] S4. Glaze spraying: put the simulated rough stone glaze prepared in step S3 into the glaze spraying air gun in the glaze spray cabinet, and spray the prepared ceramic body until it is filled with concave and convex effects;

[0025] S5. Glaze firing: wipe the bottom...

Embodiment 2

[0027] A method for preparing simulated rough stone-glazed ceramics, comprising the following steps:

[0028] S1. Prepare the basic glaze: take 15 parts of aluminum powder, 30 parts of quartz, 30 parts of potassium feldspar, 10 parts of kaolin, 5 parts of calcium carbonate, and 10 parts of barium carbonate, and mix them evenly to obtain the basic glaze;

[0029] S2. Prepare the base material: take 85-90% of the base glaze prepared in step S1, 10-15% of the white pigment, and 0.05-0.1% of sodium phosphate, and mix evenly;

[0030] S3. Mix the base material prepared in step S2 with water at a ratio of 1:0.6 to 0.8, put it into a ball mill and grind it for 12 hours, and the remaining residue accounts for 0.08% to 0.12% of the total mass. After filtering through iron removal, simulated rough stone glaze.

[0031] S4. Glaze spraying: put the simulated rough stone glaze prepared in step S3 into the glaze spraying air gun in the glaze spray cabinet, and spray the prepared ceramic bo...

Embodiment 3

[0034] A method for preparing simulated rough stone-glazed ceramics, comprising the following steps:

[0035] S1. Prepare the basic glaze: take 15 parts of aluminum powder, 30 parts of quartz, 30 parts of potassium feldspar, 10 parts of kaolin, 5 parts of calcium carbonate, and 10 parts of barium carbonate, and mix them evenly to obtain the basic glaze;

[0036] S2. Prepare the base material: take 85-90% of the base glaze prepared in step S1, 10-15% of the gray pigment, and 0.05-0.1% of sodium phosphate, and mix evenly;

[0037] S3. Mix the base material prepared in step S2 with water at a ratio of 1:0.6 to 0.8, put it into a ball mill and grind it for 12 hours, and the remaining residue accounts for 0.08% to 0.12% of the total mass. After filtering through iron removal, simulated rough stone glaze.

[0038] S4. Glaze spraying: put the simulated rough stone glaze prepared in step S3 into the glaze spraying air gun in the glaze spraying cabinet, adjust the nozzle of the glaze ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com