UV decorative ink for PET sheet and preparation method thereof

A decorative ink and sheet technology, applied in the field of UV decorative ink and its preparation, can solve problems such as deformation of PET sheets, and achieve the effects of excellent water resistance, strong hand feeling, and easy use and storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the preparation process of the UV decorative ink for PET sheet of an embodiment of the present invention is as follows:

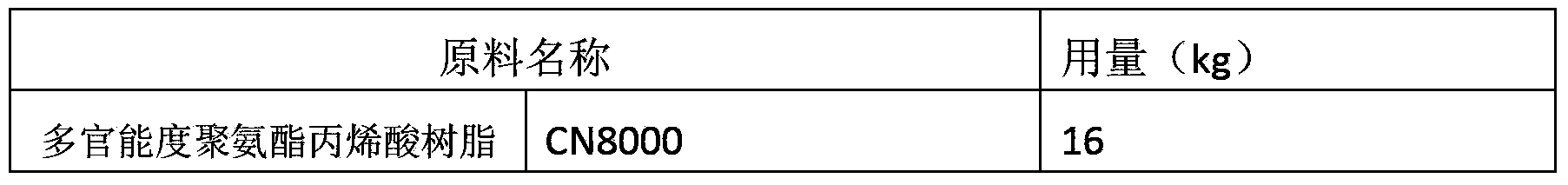

[0028] The type and weight (Kg) of the raw materials used are as follows:

[0029]

[0030]

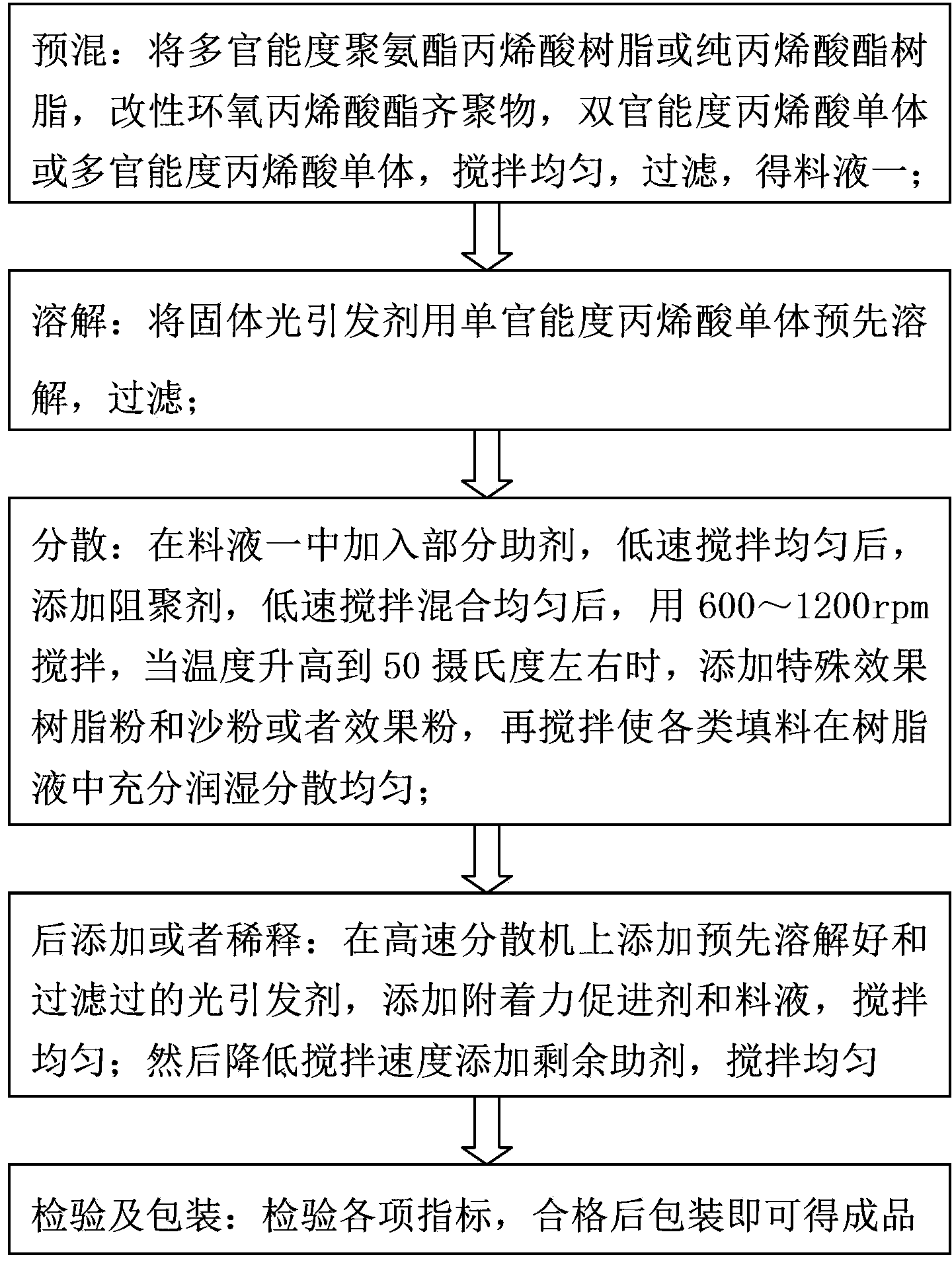

[0031] refer to figure 1 As shown in the flow chart of the preparation steps, the preparation process steps are:

[0032] (1) Premixing: multifunctional polyurethane acrylic resin CN8000, 3000B and pure acrylate resin EB745, modified epoxy acrylate EB3701, bifunctional acrylic monomer TPGDA, stirred evenly in a stirring tank, filtered, and obtained liquid one;

[0033] (2) Dissolution: pre-dissolve 184, TPO photoinitiator with CD9051 monomer, and filter;

[0034] (3) Dispersion: Add KS66 to the material liquid 1, stir evenly at a low speed, add the polymerization inhibitor p-hydroxyanisole at the same time, stir at a low speed and mix evenly, stir at 600-1200rpm, when the temperature rises to about 50 degrees Celsius , add C300 and 53...

Embodiment 2

[0041] Embodiment 2: the preparation process of the UV decorative ink for PET sheet of another embodiment of the present invention is as follows:

[0042] The type and weight (Kg) of the raw materials used are as follows:

[0043]

[0044]

[0045] refer to figure 1 As shown in the flow chart of the preparation steps, the preparation process steps are:

[0046] (1) Premixing: Stir 611B85, 7000B, CN745 and R-115W in a stirring tank evenly, filter to obtain material liquid 1;

[0047] (2) Dissolution: pre-dissolve 907 photoinitiator with SR395NSHE NNDMA, and filter;

[0048](3) Dispersion: Add 6800, 1173 to the material liquid 1, stir evenly at a low speed, add polymerization inhibitor ST-1 at the same time, stir at a low speed and mix evenly, stir at 600-1200rpm, when the temperature rises to about 50 degrees Celsius , add C800, S395N, SY-350, and stir for another 30 minutes to fully wet and disperse all kinds of fillers in the resin liquid;

[0049] (4) Post-addition...

Embodiment 3

[0055] Embodiment three: the preparation process of the UV decorative ink that is used for PET sheet of another embodiment of the present invention is as follows:

[0056] The type and weight (Kg) of the raw materials used are as follows:

[0057]

[0058]

[0059] refer to figure 1 As shown in the flow chart of the preparation steps, the preparation process steps are:

[0060] (1) Premixing: Stir CN704, SA345, 7600B, UVE150 and HDDA in a stirring tank evenly, filter to obtain material liquid 1;

[0061] (2) Dissolution: pre-dissolve 651, EDAB, ITX photoinitiator with EM210 and HY-10, and filter;

[0062] (3) Dispersion: add part of FORMER N to material liquid 1, stir evenly at low speed, add polymerization inhibitor 510 at the same time, stir at low speed and mix evenly, stir at 600-1200rpm, when the temperature rises to about 50 degrees Celsius, Add C400, 991, SY-350 and stir for another 30 minutes to fully wet and disperse all kinds of fillers in the resin liquid; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com