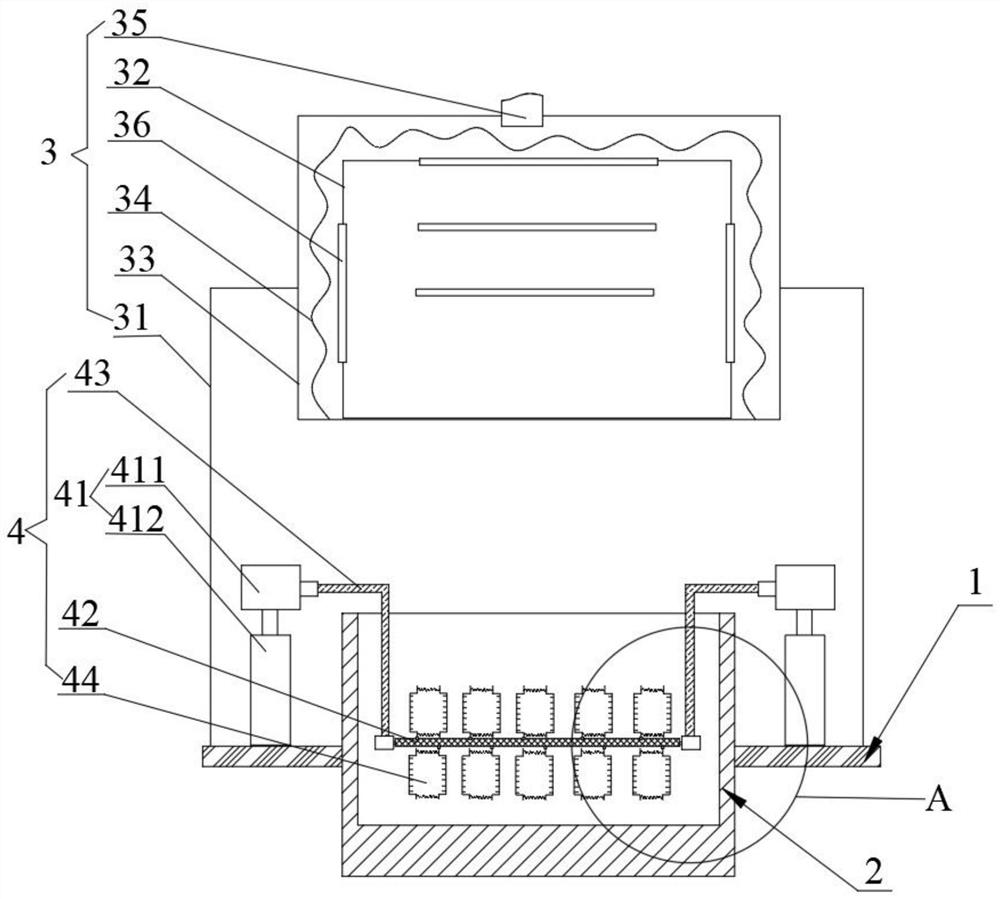

Electroplating machine and electroplating method

A technology of electroplating machine and electroplating tank, which is applied in the direction of electrolysis process and electrolysis components, etc. It can solve the problems of inability to electroplate, low production efficiency, poor electroplating effect, etc., and achieve uniform contact, good electroplating effect, and reduce manual contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

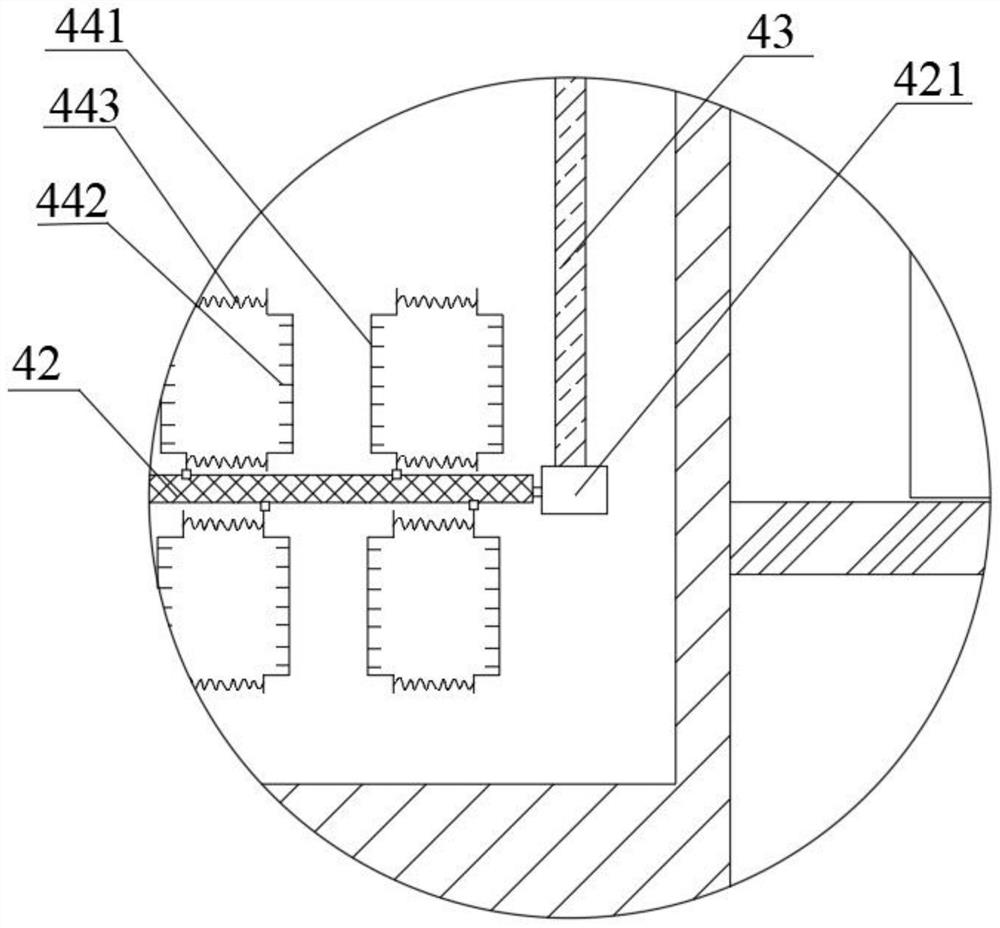

[0028] Clamp the cylindrical workpiece to be electroplated on the workpiece holder in turn, control the rotation of the flipping assembly, immerse the workpiece in the electroplating solution in the electroplating tank, and perform the electroplating operation; control the rotation of the flipping assembly to rotate the electroplated workpiece to the alignment The direction of the drying cover, lift the workpiece into the drying cover, control the drying cover to dry the workpiece; after the drying is completed, lower the workpiece out of the drying cover, and then control the flipping component to flip the workpiece to facilitate removal of the workpiece. The electroplating effect is good, and the batch electroplating has high production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com