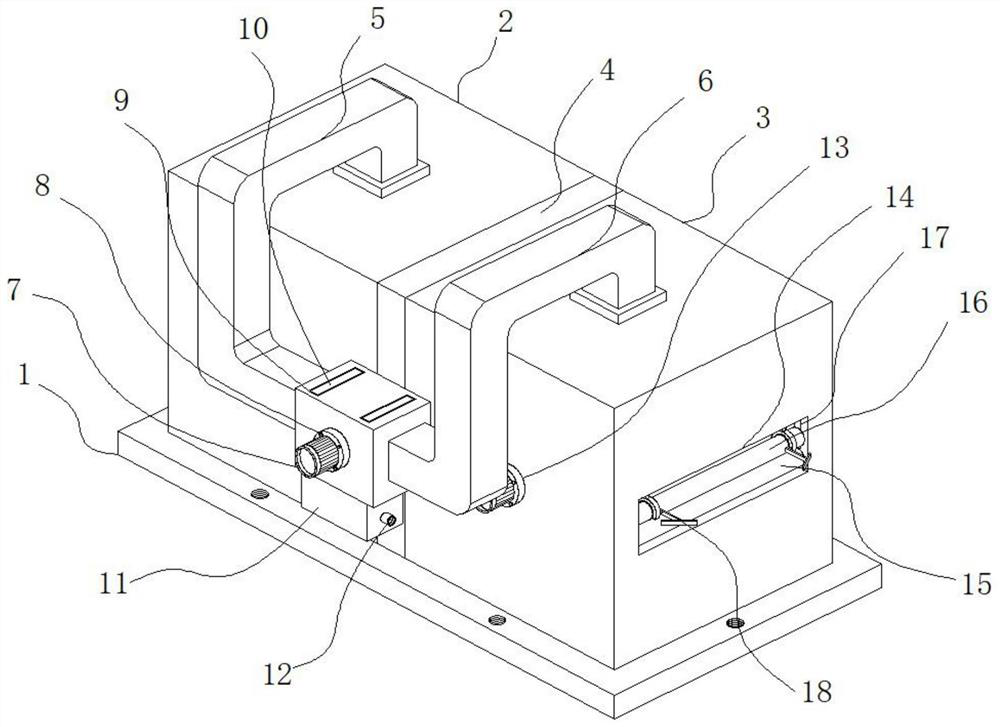

Rapid drying device for garment printing and dyeing

A technology of rapid drying and drying device, which is applied in the processing of textile materials, the configuration of equipment for processing textile materials, and the removal of liquid/gas/vapor with squeeze rollers, which can solve the problems of high time consumption, low drying efficiency of the device, Problems such as slow drying speed to avoid curling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

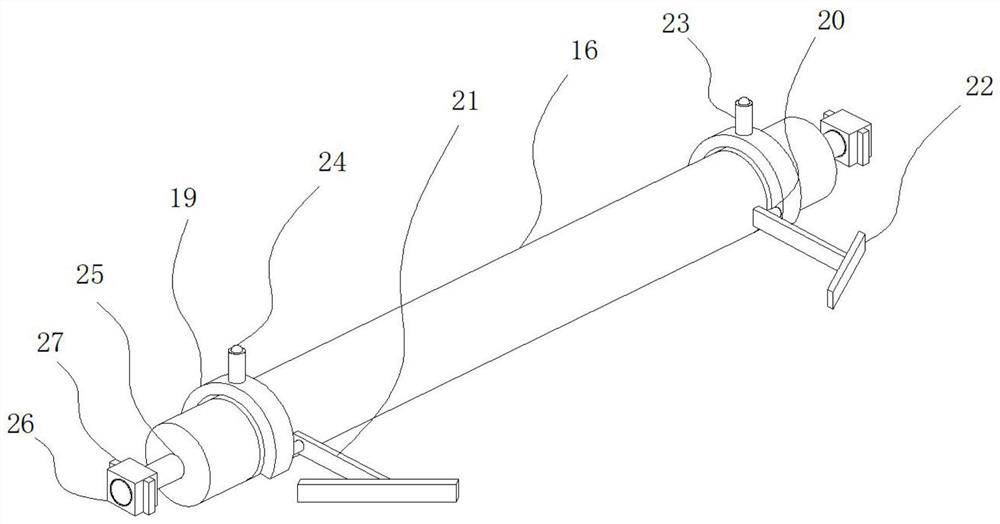

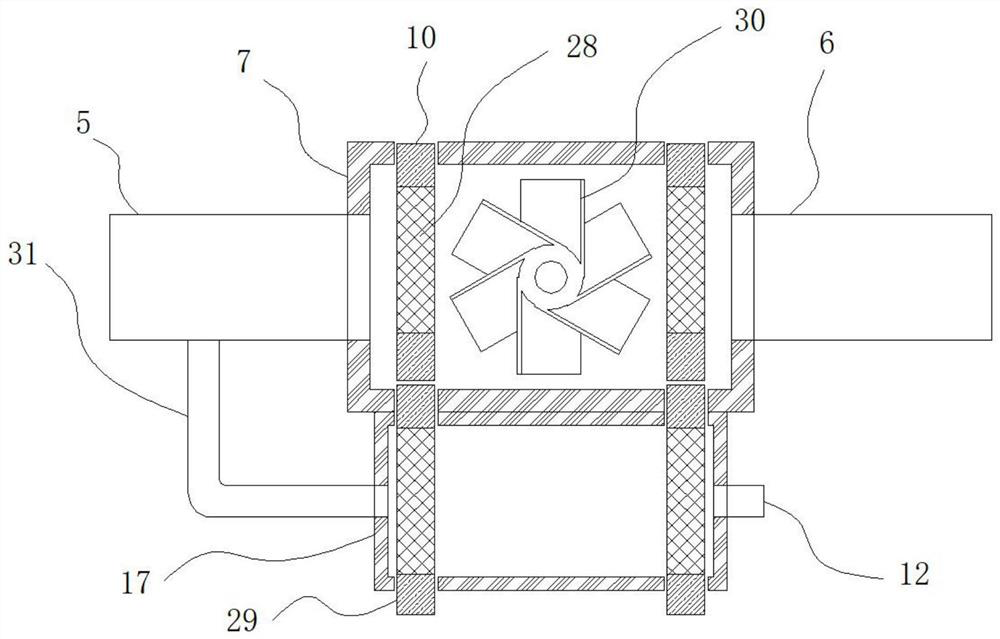

[0027] As a preferred embodiment of the present invention, the anti-rolling device 18 includes an arc frame 19, a rotating rod 20 is installed on one side of the inner wall of the arc frame 19, and a support rod 21 is installed on the rotating rod 20, One end of the support rod 21 is welded with a slant plate 22 , the two ends of the upper roll 16 are fixed with mounting columns 25 , and the two ends of the mounting column 25 are equipped with sliders 26 .

[0028] As a preferred embodiment of the present invention, the mounting column 25 is installed inside the chute 17 through the slider 26, the two sides of the slider 26 are welded with limit blocks 27, and the inner wall of the chute 17 has a There is a limit slot, and the limit block 27 is installed inside the limit slot.

[0029] As a preferred embodiment of the present invention, the top of the arc-shaped frame 19 is welded with a support column 23, the inside of the support column 23 has a cavity, the inside of the cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com