Marine low-temperature liquid fuel or cargo filling hose support and filling system

A low-temperature liquid and hose technology, which is applied to liquid materials, pipe supports, liquid treatment, etc., can solve the problem that the filling joint is affected by the shaking of the ship and the filling joint, so as to avoid shaking and slipping, improve safety, and reduce the pressure on the terminal. Part load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

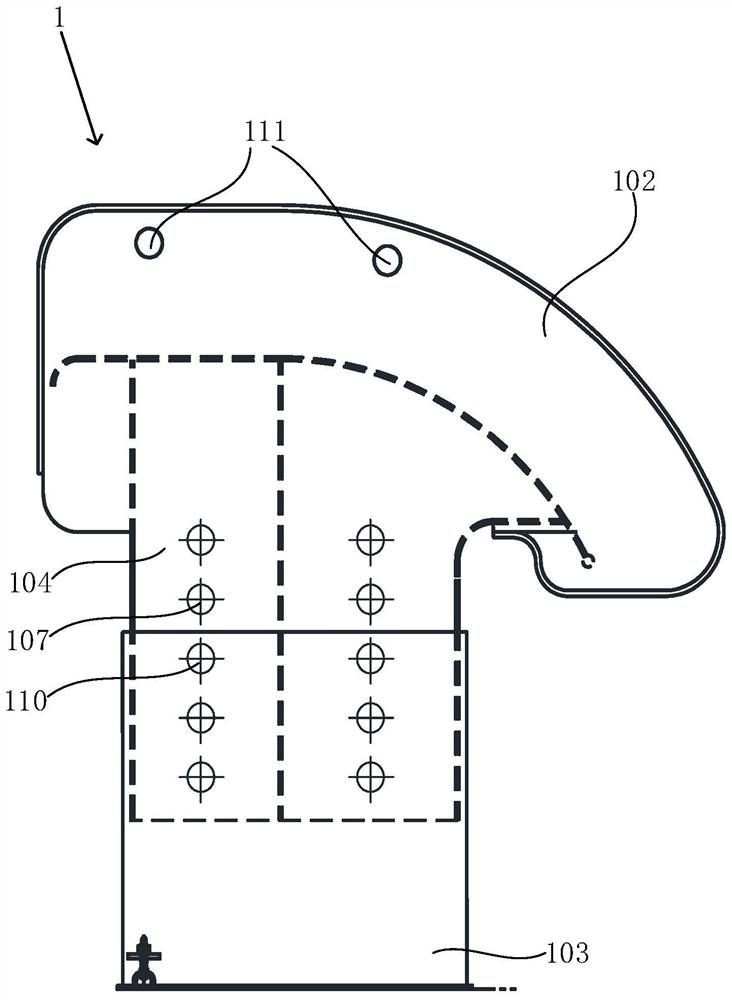

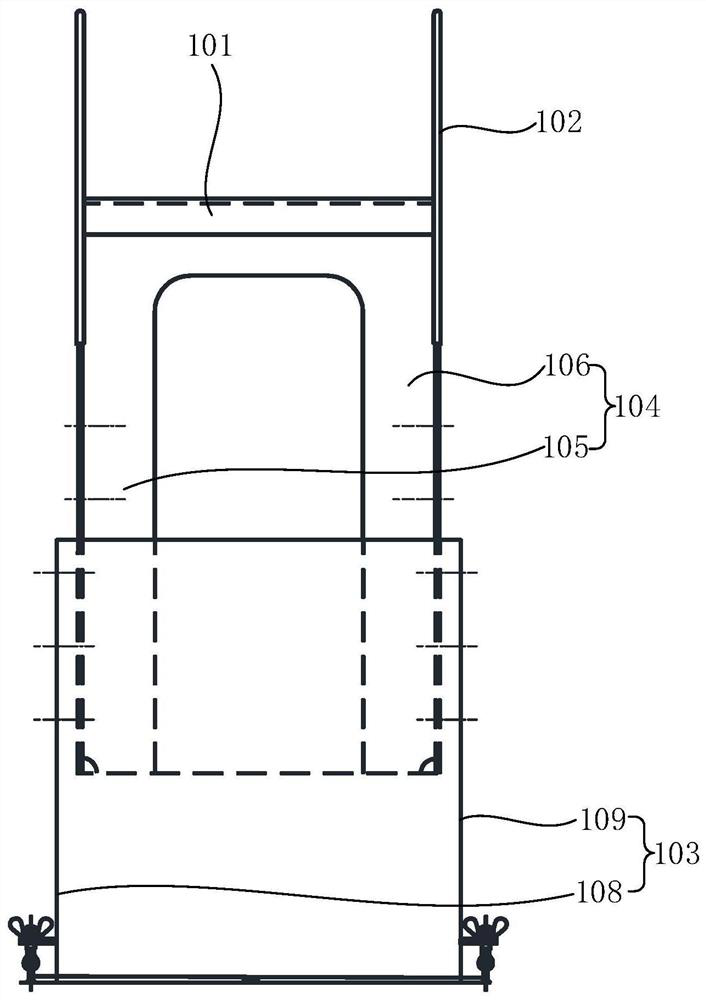

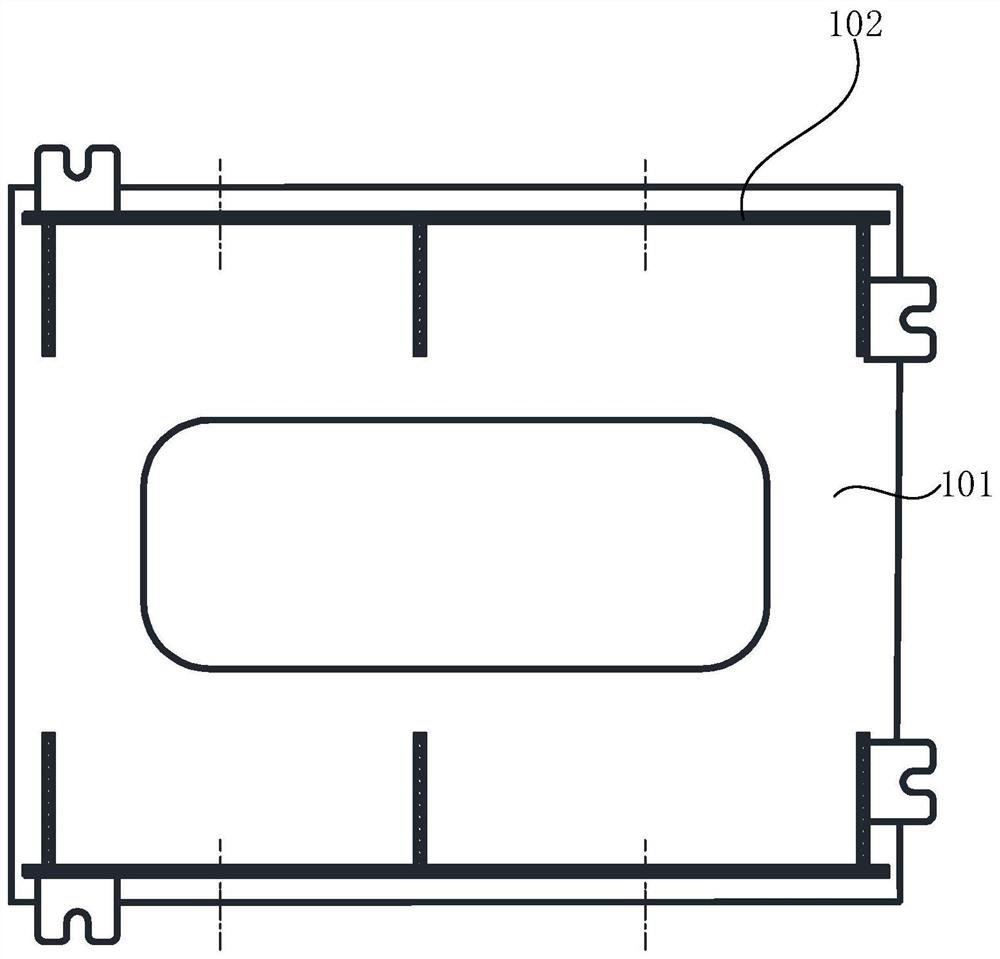

[0057] Such as Figure 1-Figure 3 As shown, this embodiment provides a marine cryogenic liquid fuel or cargo filling hose support 1, which includes an arc-shaped bracket 101, a baffle 102 and a base 103, and the two baffles 102 are respectively fixed On both sides of the bracket 101 and extending upward from the bracket 101 , the bracket 101 is connected to a base 103 , and the base 103 is used for fixedly installing the hose support 1 for marine cryogenic liquid fuel or cargo filling.

[0058]The bracket 101 includes a horizontal section and an arc section, the arc section corresponds to a central angle of about 90°, and the high point of the arc section is tangent to the horizontal section and fixedly connected. Both sides of the bracket 101 are fixedly connected with vertical baffles 102 , the baffles 102 extend upwards, and the height of the baffles 102 extending out of the bracket 101 is at least higher than the radius of the filling hose 3 being jacked up. The bottom of...

Embodiment 2

[0074] The parts of the second embodiment that are the same as those of the first embodiment will not be repeated, and only the different parts will be described. In Embodiment 1, the upper edge of the baffle plate 102 is provided with stainless steel wrapping corners, and in Embodiment 2, the upper edge of the baffle plate 102 is provided with arc curling.

[0075] The upper edges of the two side baffles 102 are provided with arc curling.

[0076] The upper edges of the baffles 102 on both sides are all rolled outwards to form arc-shaped curls, so that the original upward sharp side of the baffles 102 is rolled down to the side, and then the baffles 102 are curled on the upper side, avoiding The sharp side of the baffle 102 is placed directly upward, so as to protect the filling hose 3 from being scratched by the sharp baffle 102 when it is hoisted on the bracket 101 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com