Fuel cell system and method of controlling fuel cell system

A fuel cell system, fuel cell technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of increased calorific value, no disclosure, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

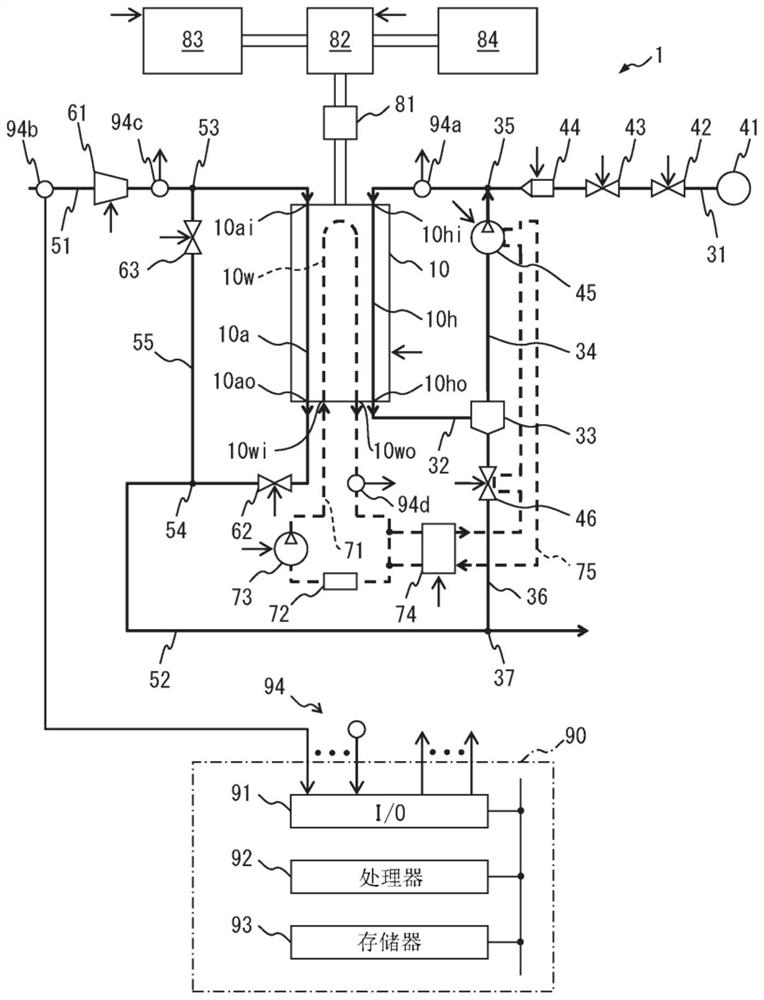

[0053] refer to figure 1 , in the embodiment based on the present disclosure, the fuel cell system 1 includes a fuel cell 10 . The fuel cell 10 is formed by laminating a plurality of single cells. The fuel cell 10 includes a hydrogen passage 10h, an air passage 10a, and a cooling water passage 10w. In one example, the fuel cell system 1 is mounted on a vehicle.

[0054] In the embodiment based on the present disclosure, the hydrogen passage 10h extends from the inlet 10hi to the outlet 10ho within the fuel cell 10 . An anode (not shown) is arranged in the hydrogen passage 10h. A hydrogen supply path 31 is connected to the inlet 10hi. A hydrogen discharge path 32 is connected to the outlet 10ho. The outlet of the hydrogen discharge path 32 is connected to the inlet of the gas-liquid separator 33 . The upper outlet of the gas-liquid separator 33 is connected to the junction 35 of the hydrogen supply path 31 via the return path 34 . A lower outlet of the gas-liquid separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com