Waste metal recovery device

A recycling device and waste metal technology, which is applied in the field of environmental governance, can solve the problems of cutting metal objects that increase the difficulty of environmental governance, affect the recycling of old metals, and have low adhesion, and achieve the effect of reducing the intensity of manual processing and facilitating recycling operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

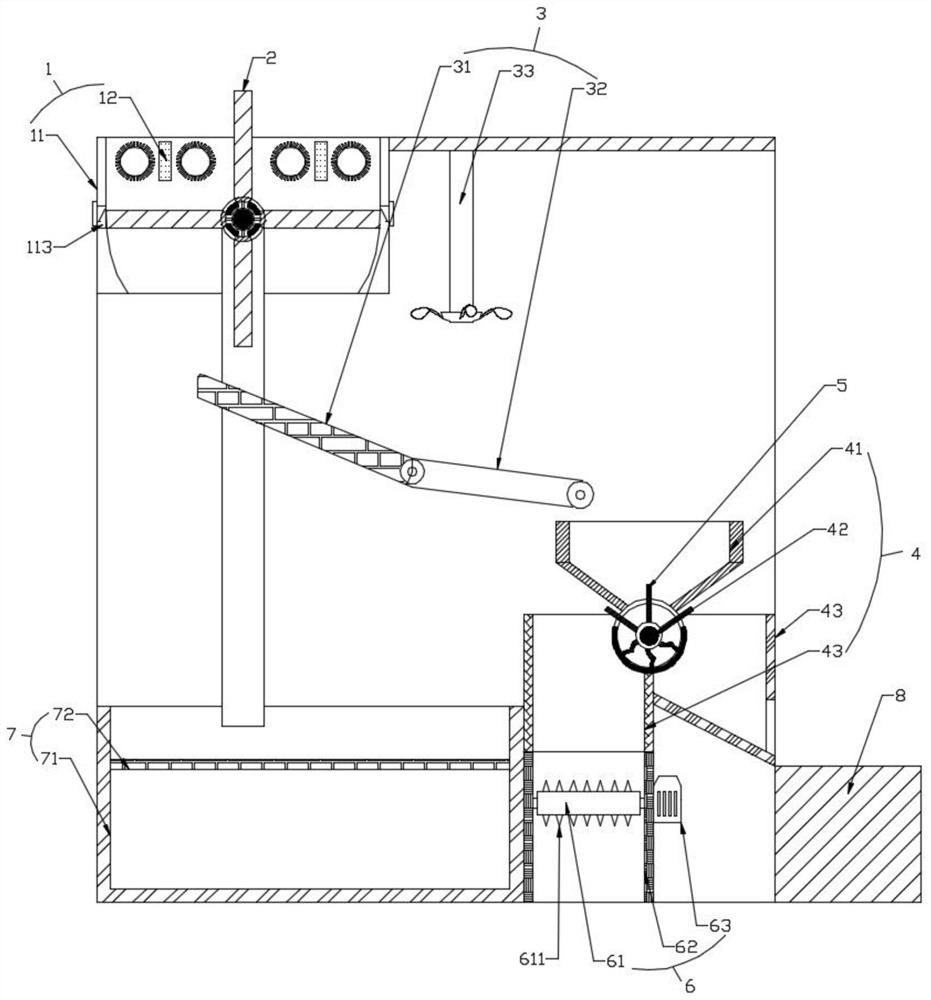

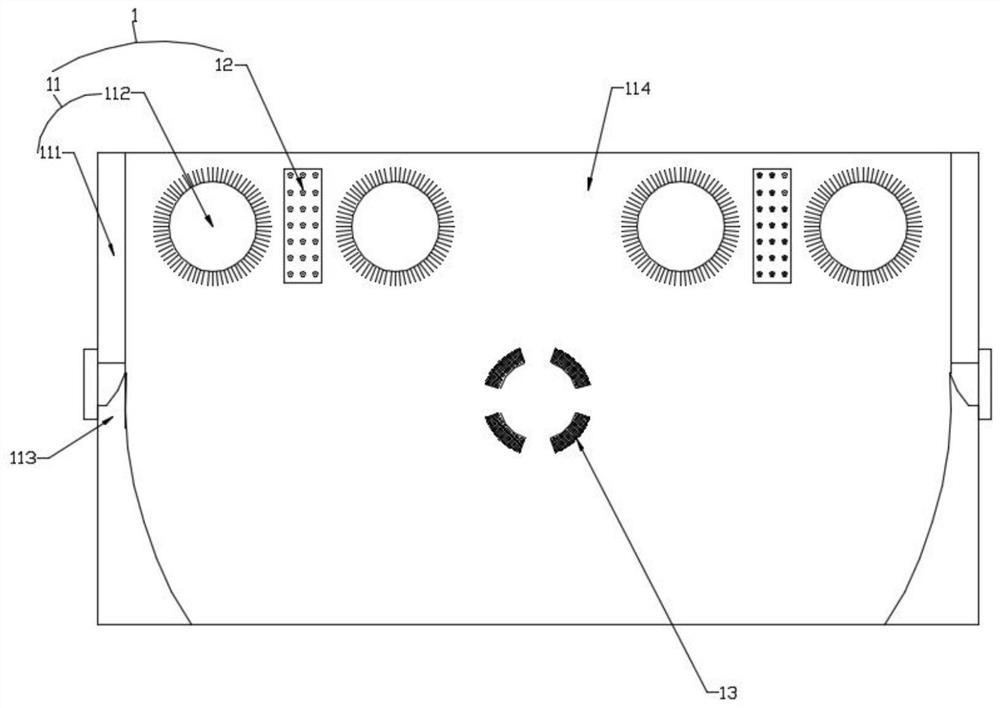

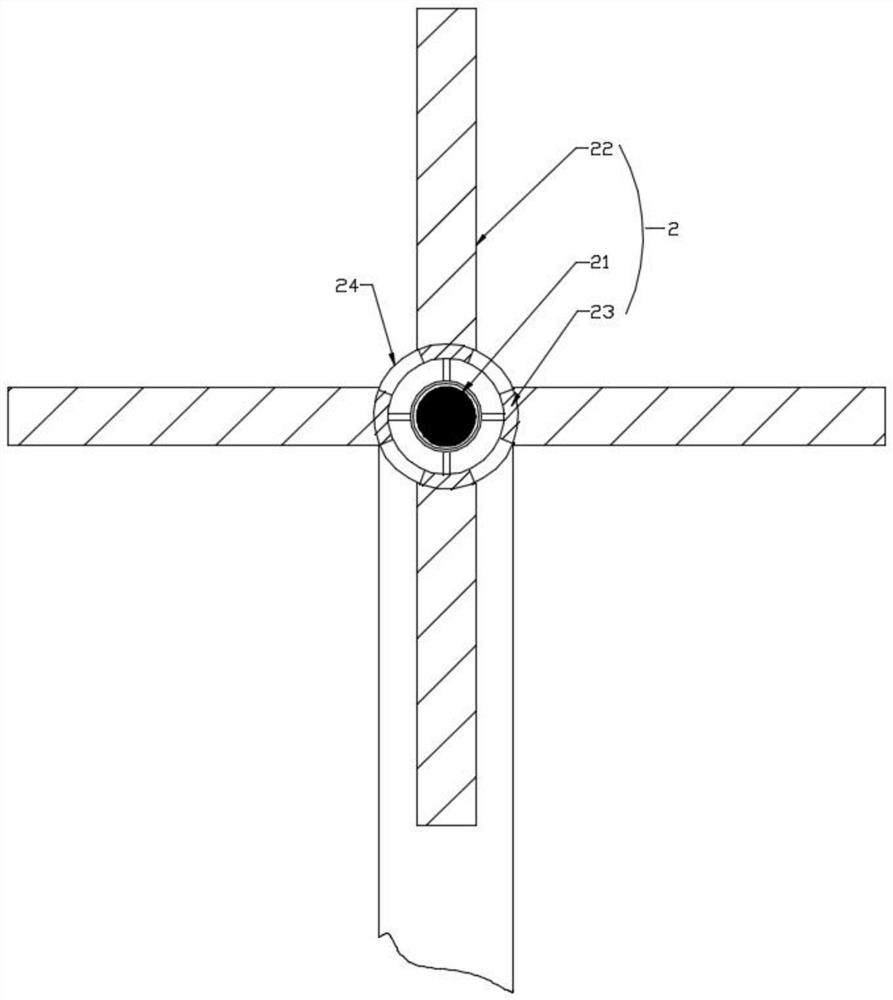

[0040] Because the existing scrap metal recovery device is difficult to effectively remove the stains and oxides attached to the scrap metal during the cleaning operation, and the main function of the existing scrap metal recovery device is to crush the scrap metal, and its function is relatively single. For this reason the present invention has designed a kind of scrap metal recycling device, as Figure 1-5 As shown, it includes: a pretreatment unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com