Preparation method and reaction device of microcarrier suitable for three-dimensional cell culture

A technology for preparing a device and a liquid, which is applied in the field of preparation of microcarriers and can solve the problems of limited production volume of production methods and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0139] Oil ratio

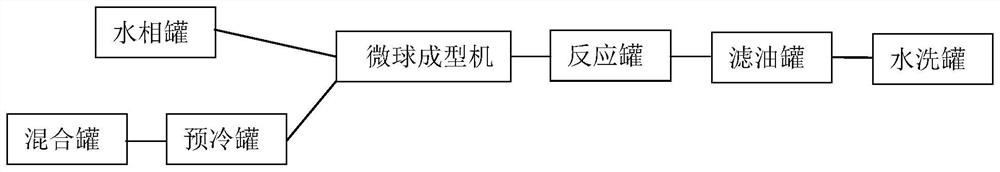

[0140] 1.1 First check the cleanliness of the mixing tank, pre-cooling tank, liquid sterilizing filter, measuring tools and site clearing records. They are clean and can be used within the clearing period;

[0141] 1.2 Take 100L of petroleum ether and 10L of PO-500 reagent into the mixing tank sequentially using a peristaltic pump. Open the mixing tank and stir, and the rotating speed is set at 60rpm to stir for 1 hour;

[0142] 1.3 Close the tank body of the mixing tank and only keep the compressed air port open, until the internal pressure of the tank body reaches 0.1MP, pour the oil phase into the pre-cooling tank. Through the continuous cooling of the chiller, the temperature of the oil phase is reduced to -10°C for standby, and the agitation of the pre-cooling tank can be kept at 40rpm during this period.

[0143] water ratio

[0144] 2.1 First check the cleanliness of the water phase tank, measuring tools and site clearance records, and they can be ...

Embodiment 2

[0164] Oil ratio

[0165] 1.1 Inspection device, same as embodiment 1;

[0166] 1.2 Measure 80L of chloroform, 20L of petroleum ether, and 10L of Tween 20 reagent and add them to the mixing tank sequentially using a peristaltic pump. Open the mixing tank and stir, and the rotating speed is set at 60rpm to stir for 1 hour;

[0167] 1.3 Close the tank body of the mixing tank and only keep the compressed air port open, until the internal pressure of the tank body reaches 0.1MP, pour the oil phase into the pre-cooling tank. Through the continuous cooling of the chiller, the temperature of the oil phase is reduced to -30°C for standby, and the agitation of the pre-cooling tank can be kept at 40rpm during this period.

[0168] water ratio

[0169] 2.1 Inspection device, same as embodiment 1;

[0170] 2.2 Weigh 50g of gelatin + 10g of sodium alginate and put it into 1.5L deionized water. Set the agitator at 60rpm to stir the gelatin solution until it is fully dissolved. Use a peris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com