Silicon carbide crystal with few small-angle grain boundaries, substrate and preparation method thereof

A silicon carbide substrate, small-angle grain boundary technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems of unfavorable access to high-quality silicon carbide crystals, and achieve low stress and low dislocation density , high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] The diagram of this embodiment does not show the structure of the heat preservation ring, and this embodiment mainly describes the structure of the air layer.

[0087] The crucible 2 is a graphite crucible, and the size of the silicon carbide seed crystal in the crucible 2 is 100-350 mm.

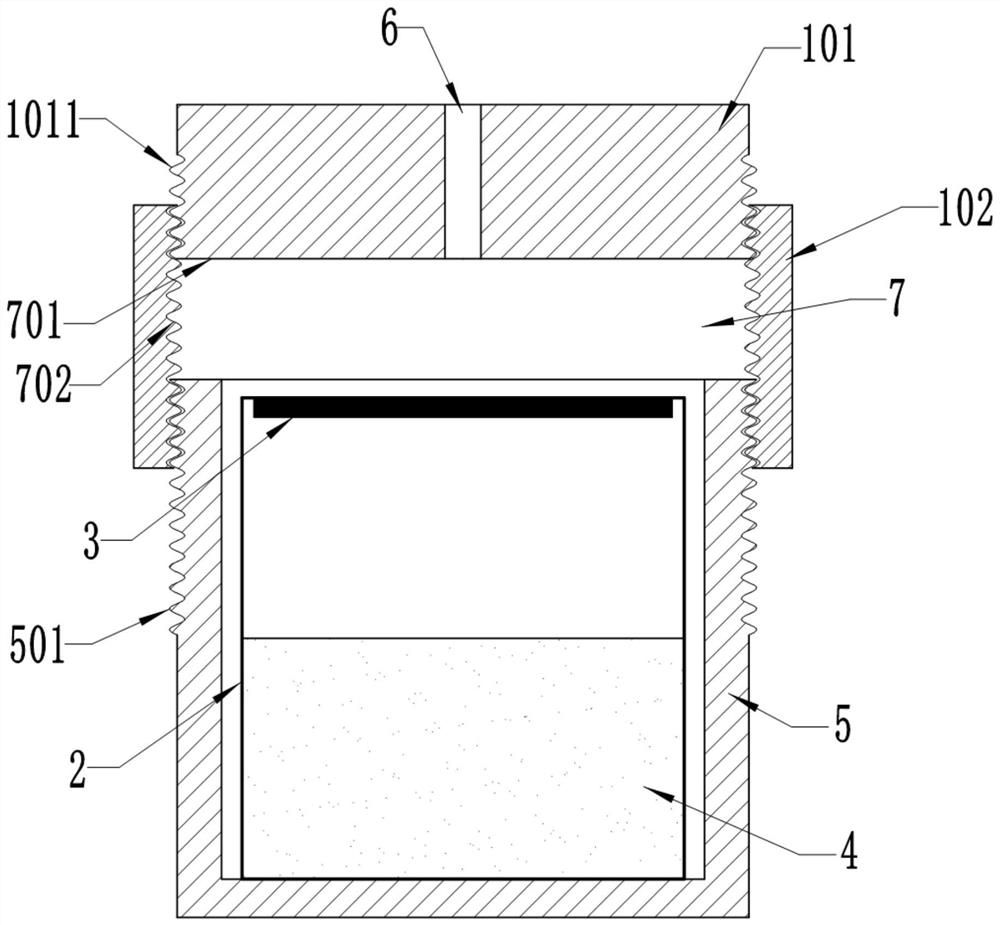

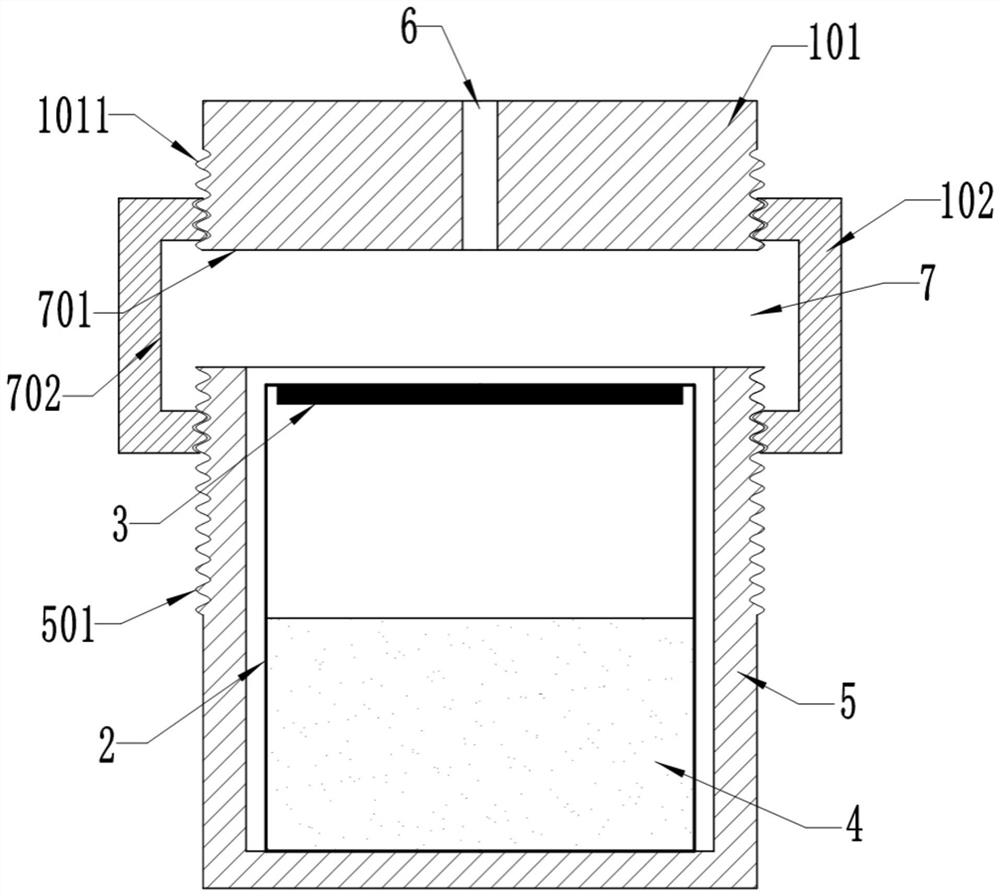

[0088] refer to Figure 1-3 The insulation layer includes a lower insulation layer, an upper insulation layer 101, a side insulation layer 5 and a transition insulation layer 102. The lower insulation layer, the upper insulation layer 101, the side insulation layer 5 and the transition insulation layer 102 form an insulation cavity, and the upper insulation layer 101 A temperature measuring hole is provided; the transition insulation layer 102 is at least threadedly connected to one of the upper insulation layer 101 and the side insulation layer 5, and is integrally formed with the other, and the transition insulation layer 102 is threaded between the upper insulation layer 101 and th...

Embodiment 2

[0098] In this embodiment, a schematic diagram of the structure of adding a heat preservation ring is described in conjunction with Embodiment 1. The part not shown in Embodiment 1 in this embodiment is that a heat preservation ring can be directly placed between the crucible and the upper heat preservation layer.

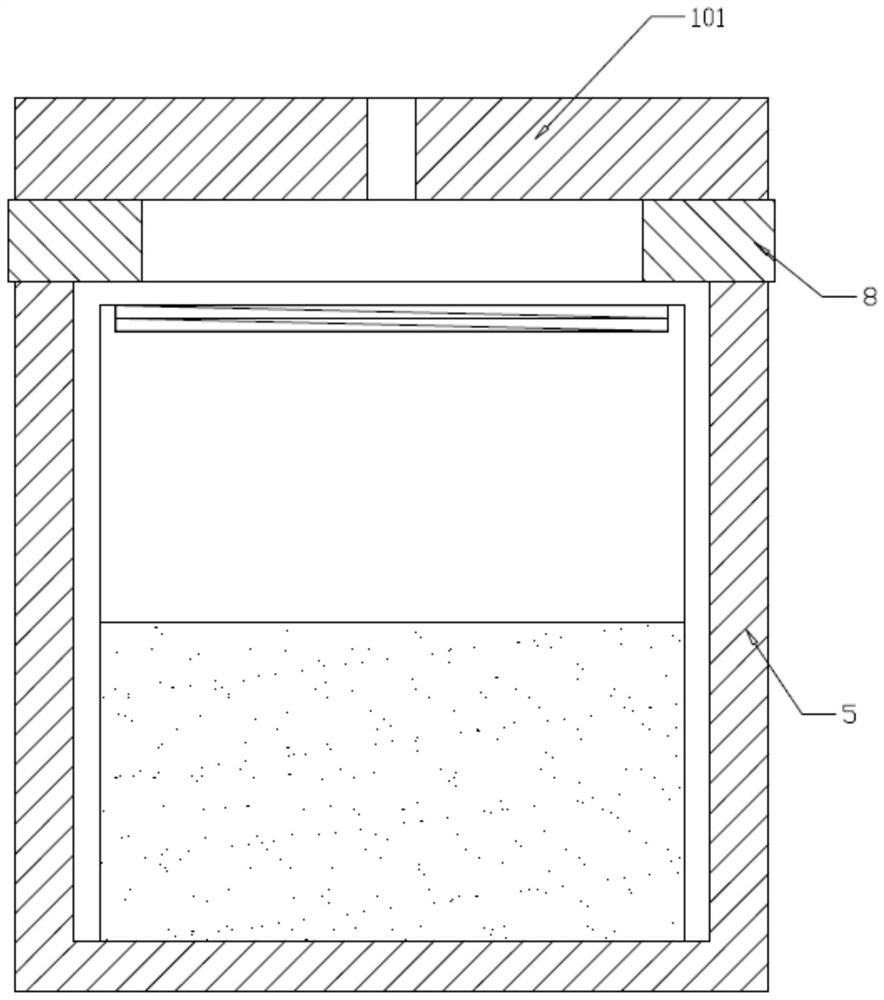

[0099] refer to Figure 4 The difference between this embodiment and Example 1 is that the thermal insulation layer includes a lower thermal insulation layer, an upper thermal insulation layer 101, a side thermal insulation layer 5 and a thermal insulation ring 8, and the thermal insulation ring 8 is connected between the upper thermal insulation layer 101 and the side thermal insulation layer 5. , the lower thermal insulation layer, the upper thermal insulation layer 101, the side thermal insulation layer 5 and the thermal insulation ring 8 enclose a thermal insulation cavity.

[0100] refer to Figure 5 , this embodiment and Example 1 figure 1 The difference be...

Embodiment 3

[0104] The method for preparing a silicon carbide substrate using any of the insulating layers and the crucible contained in Embodiment 2 includes the following steps:

[0105] 1) Assembling: provide bearing raw materials and seed crystals arranged on the top of the crucible, place the crucible in the heat preservation cavity formed by the heat preservation layer, and then place it in the crystal growth furnace; wherein, the heat preservation layer includes a heat preservation ring placed above the crucible, which keeps the heat preservation effect. The ring covers at least 0.5mm to 0.5r-0.5mm extending inward from the edge of the seed crystal, where r is the radius of the seed crystal;

[0106] 2) Crystal growth: silicon carbide crystals are prepared by growing crystals, and the edges of the obtained silicon carbide crystals form an annular shape roughly corresponding to the covering position of the insulation ring;

[0107] 3) Preparing a primary silicon carbide substrate: p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com