Local reinforcing structure of road subgrade and implementation process

A technology of local strengthening and roadbed, applied in the direction of roads, roads, road repair, etc., can solve the problems of low detection efficiency, damage to the roadbed, and long detection time, and achieve the effects of convenient operation, improved efficiency and high construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

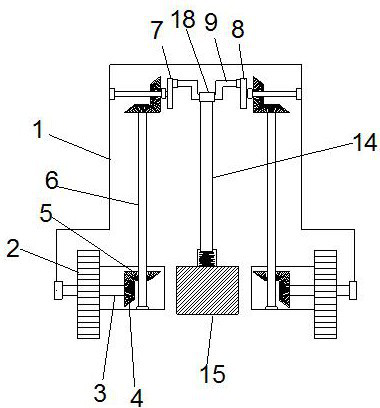

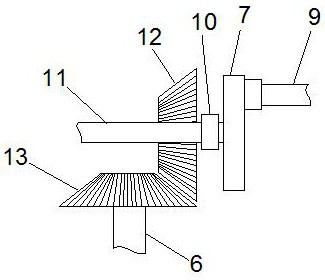

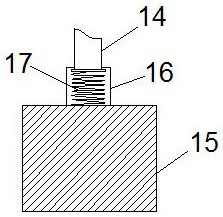

[0035] Such as Figure 1-3 As shown, a local reinforcement structure of a road subgrade includes a mechanical module and a detection module; the mechanical module includes a housing 1, and the bottom of the housing 1 is symmetrically provided with two runners 2, and the two runners 2 are connected with a rotating shaft 3, and the runner 2 is rotationally connected with the housing 1 through the rotating shaft 3. One end of the rotating shaft 3 is connected with a first helical gear 4, and the first helical gear 4 is meshed with a second helical gear 5. The center position of the second helical gear 5 is provided with a transmission rod 6 through which a drive mechanism is connected above the transmission rod 6 , and the lower end of the transmission rod 6 is rotationally connected with the housing 1 ;

[0036] The detection module includes a detection host, a ground penetrating radar, and the sending end of the ground penetrating radar sends electromagnetic waves to the roadbe...

Embodiment 2

[0042] Such as Figure 4-5 As shown, on the basis of Embodiment 1, the detection steps of the detection module include, the first step, the detection host reads the electromagnetic wave echo data of the ground penetrating radar; the second step, data processing is performed on the returned electromagnetic wave echo and data conversion to eliminate the influence of noise; the third step is to obtain the level map after encoding processing by the host computer, and perform edge detection processing on it; the fourth step is to obtain the thickness and pressure of the subgrade structure layer by performing edge transformation processing on the level map The real situation and the empty situation.

[0043] The host computer encodes and plays back the processed signals to obtain pseudo-color level diagrams, waveform accumulation diagrams, and grayscale level diagrams.

[0044] In the third step, the step of performing edge detection on the received pseudo-color level diagram, wave...

Embodiment 3

[0047] On the basis of Embodiment 1, a construction process for a local reinforcement structure of a road subgrade. During the compaction process, if the subgrade is detected to be empty or the compactness and thickness do not meet the requirements, the shell is pushed 1. Through the rotation of the rotation, the first helical gear 4 and the second helical gear 5 are driven to rotate, and at the same time, the transmission rod 6 drives the third helical gear 12 and the fourth helical gear 13 to rotate. When the third helical gear 12 is rotating, it passes The shaft coupling 10 drives the first cam 7 and the second cam 8 to rotate, and the crankshaft 9 rotates accordingly, and the crankshaft 9 drives the pressing rod 14 and the pressing block to perform circular reciprocating motion, and the two runners 2 rotate independently, according to the Drive the transmission rod 6 and the crankshaft 9 to rotate independently, so that the pressure rod 14 and the pressure block do reciproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com