Sludge incineration device facilitating automatic feeding

A technology of automatic feeding and sludge incineration, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of inconvenient automatic discharge continuous processing, inconvenient and thorough crushing of sludge, inconvenient automatic feeding, etc. Achieve the effect of improving processing efficiency and processing effect, avoiding too much or too little blanking, and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

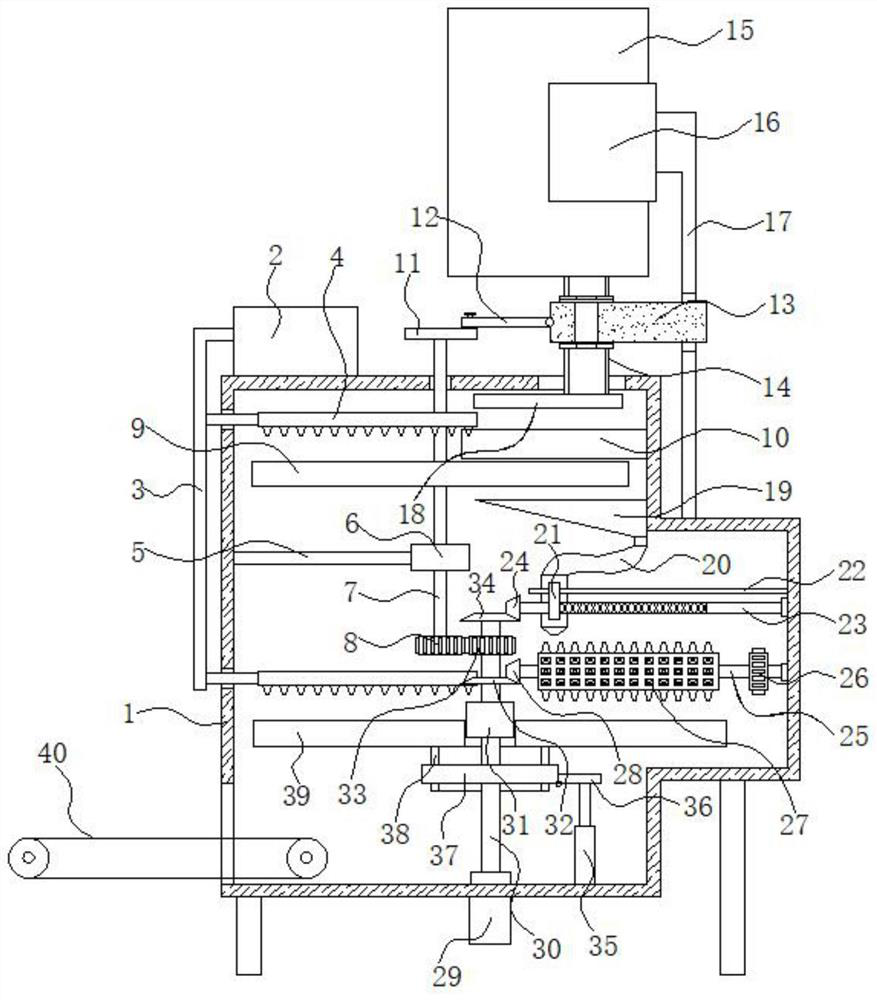

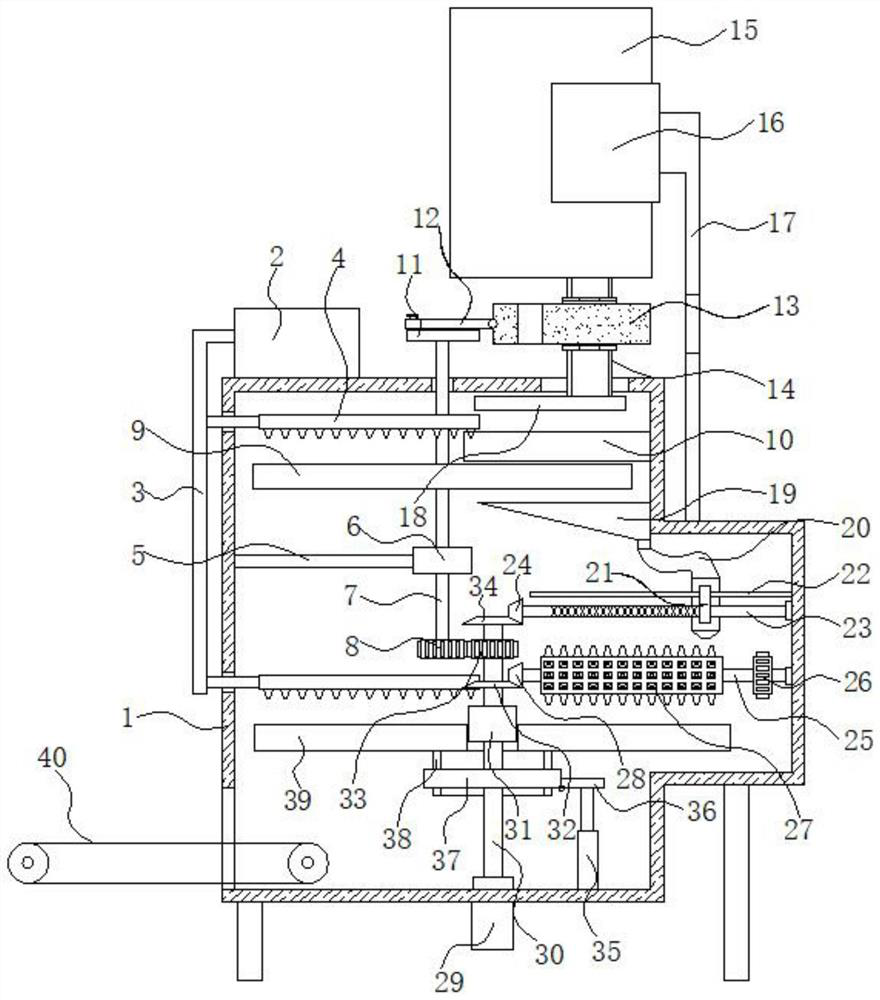

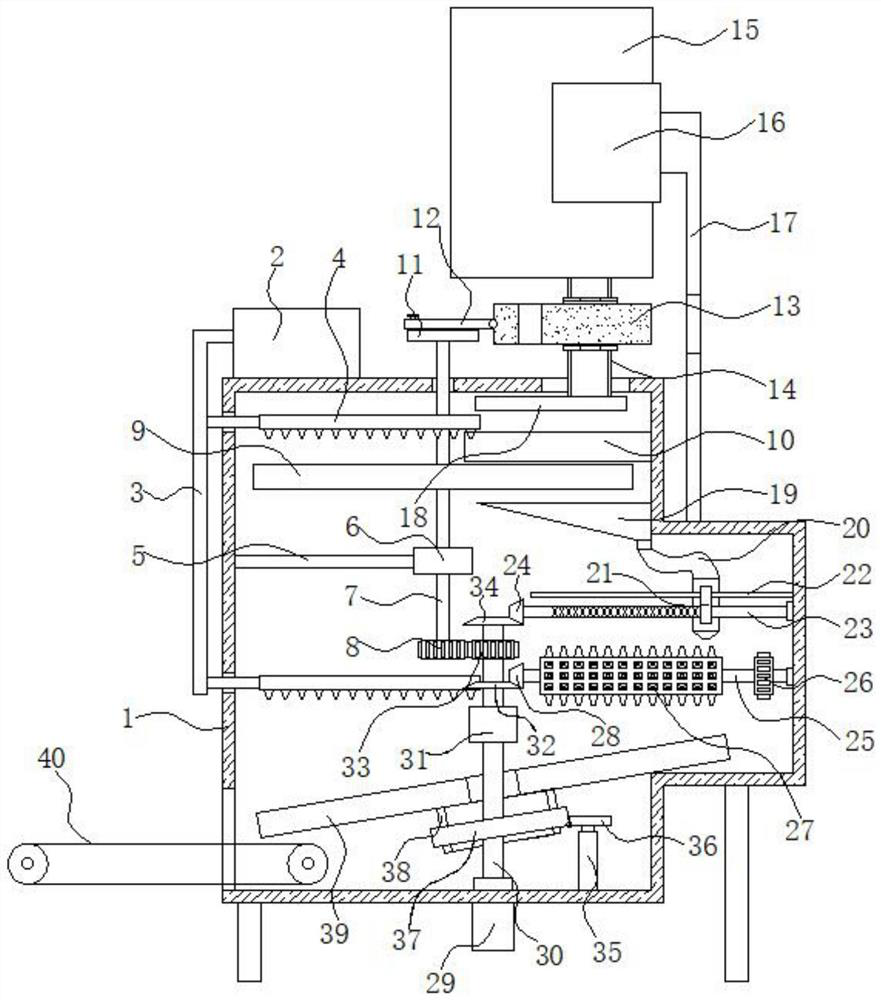

[0031] refer to Figure 1-2 and Figure 5-7 : A sludge incineration device for convenient automatic feeding, including an incineration box 1, the top left side of the incineration box 1 is fixedly connected with a fire-spraying incineration mechanism, the interior of the incineration box 1 is provided with a preliminary incineration transmission mechanism, and the right side of the preliminary incineration transmission mechanism The side is provided with a blanking crushing mechanism, the bottom of the blanking crushing mechanism is provided with a conveyor belt 40 below the left side of the secondary incineration feeding mechanism, and the top right side of the incineration box 1 is provided with a feeding mechanism.

[0032]In the present invention, the flame-spraying incineration mechanism includes a gas tank 2 fixedly connected to the top of the incineration box 1, the gas outlet of the gas tank 2 is connected with a gas pipe 3, and one end of the gas pipe 3 extending into...

Embodiment 2

[0034] refer to Figure 3-4 and Figure 8 : A sludge incineration device that facilitates automatic feeding, wherein, the blanking crushing mechanism includes a hopper 19 that is fixedly connected to the inner wall on the right side of the incineration box 1, and the bottom of the hopper 19 is fixedly sleeved with a blanking pipe 20. The pipe 20 is fixedly connected with a connection block 21, the inner movable sleeve of the connection block 21 is provided with a guide rod 22, and the right end of the guide rod 22 is fixedly connected with the right inner wall of the incineration box 1, and the internal thread sleeve of the connection block 21 is provided with a reciprocating Screw mandrel 23, the left end of reciprocating screw mandrel 23 is fixedly connected with first bevel gear 24, and the bottom of feeding pipe 20 is provided with two drive shafts 25 that are connected with the right side inner wall of incinerator box 1, and the outside of drive shaft 25 is fixed A trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com