Acid fracturing test method for fracture-vug type carbonate rock test piece

A carbonate rock, acid fracturing technology, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, instruments, etc., can solve problems that limit the research progress of carbonate rock acid fracturing tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

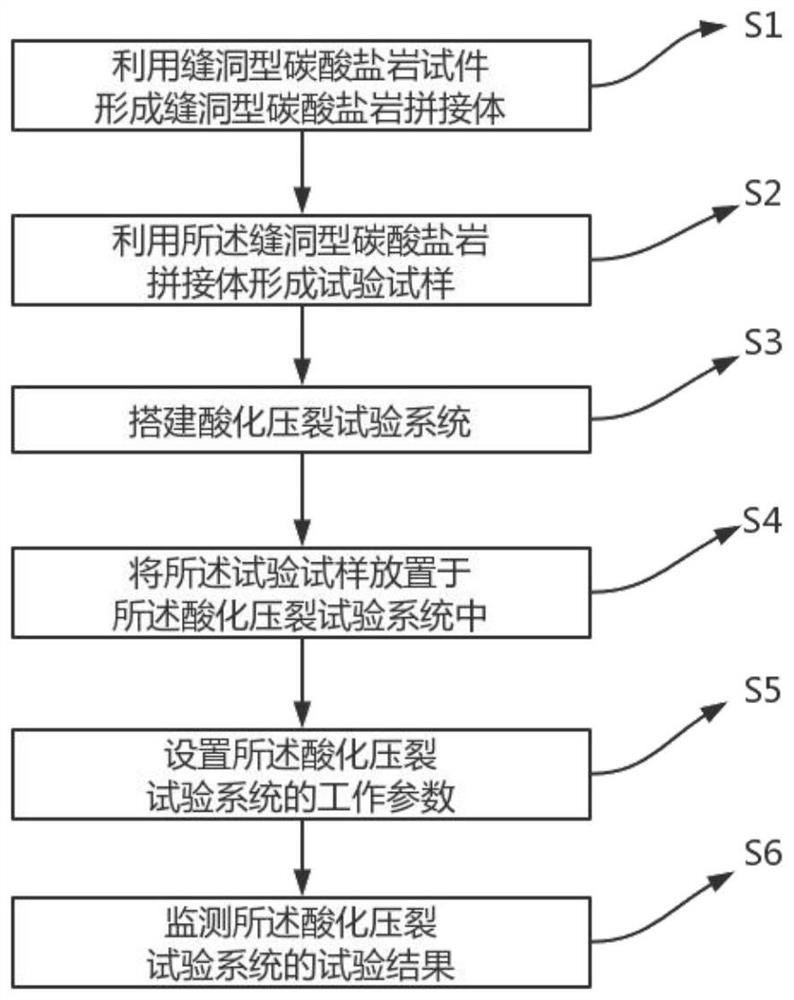

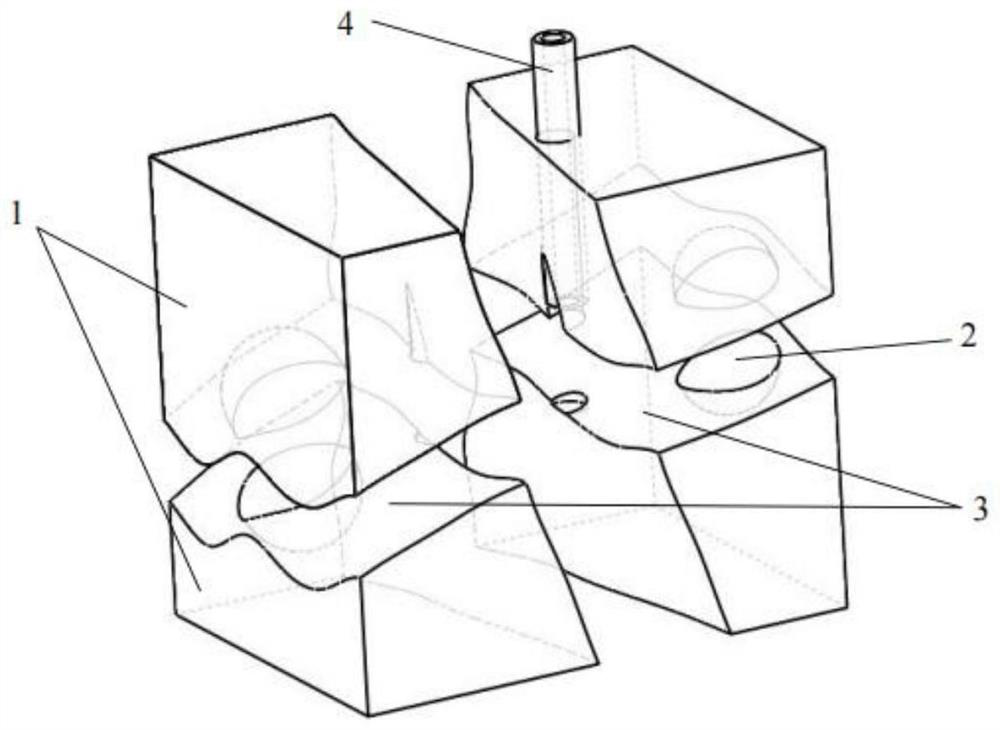

[0132] Such as Figure 2-4, in the embodiment of the present application, the regular-shaped carbonate rock block is divided into several smaller segmented blocks 1 by means of splitting, and holes are drilled or partially knocked on the segmented plane 3 of the segmented block 1. Chisel to make artificial hole 2, so as to simulate hydrochloric acid rock salt cave. The multiple split blocks 1 are rejoined and fixed according to the initial position, and the resulting spliced cracks 5 simulate natural cracks, and the gaps of the remaining spliced cracks 5 are filled with slaked lime slurry to form a crack filling layer 6 mainly composed of CaCO2. formed a complete splicing of fracture-vuggy carbonate rocks. Place the fracture-cavity carbonate rock splicing body in the center of the mold, and form the cement outer shell 7 by pouring cement slurry into the remaining space of the mold, and cure for more than 7 days to form the test piece. After the cement outer shell 7 is so...

Embodiment 2

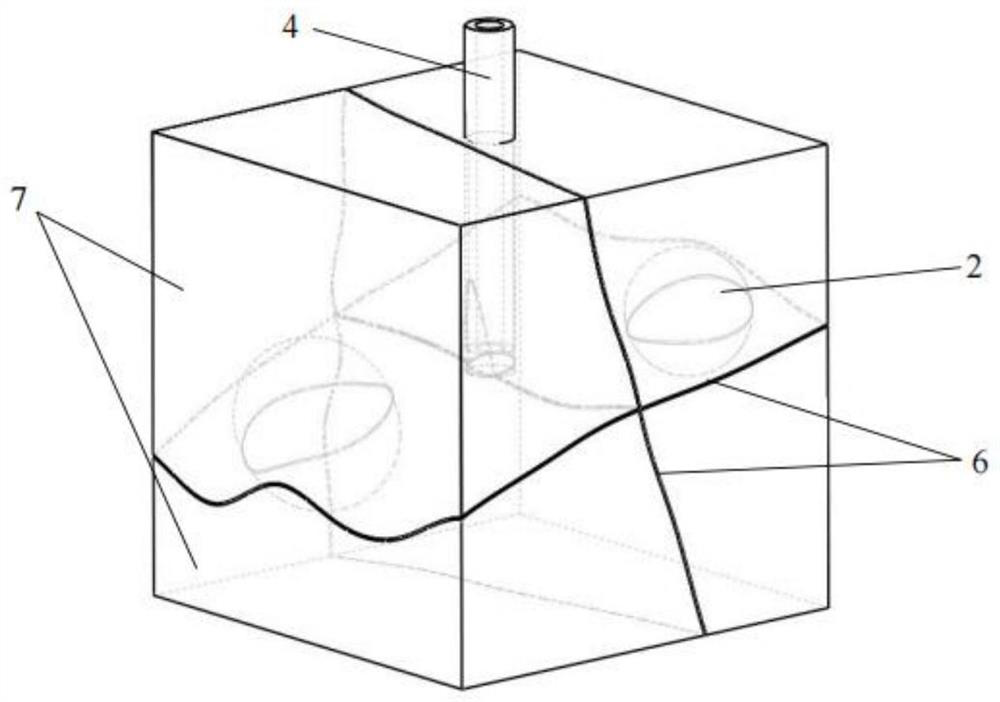

[0134] Such as Figure 5-7 , in the embodiment of the present application, the regular-shaped carbonate rock block is divided into several smaller segmented blocks 1 by means of plane cutting, and holes are drilled or partially knocked on the segmented plane 3 of the segmented block 1. Chisel to make artificial hole 2, so as to simulate hydrochloric acid rock salt cave. The multiple split blocks 1 are rejoined and fixed according to the initial position, and the resulting spliced cracks 5 simulate natural cracks, and the gaps of the remaining spliced cracks 5 are filled with slaked lime slurry to form a crack filling layer 6 mainly composed of CaCO2. formed a complete splicing of fracture-vuggy carbonate rocks. Place the fracture-cavity carbonate rock splicing body in the center of the mold, and form the cement outer shell 7 by pouring cement slurry into the remaining space of the mold, and cure for more than 7 days to form the test piece. After the cement outer shell 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com