Tobacco stem stick pressing and sheeting equipment

A stem cutting and flaking technology, which is applied in the field of tobacco leaf stalk pressing and flaking equipment, can solve the problems of increased equipment manufacturing cost, unfavorable cutting, difficult cleaning and collection, etc., and achieve low requirements on manufacturing performance, improve shape consistency, Withstand the effect of small impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

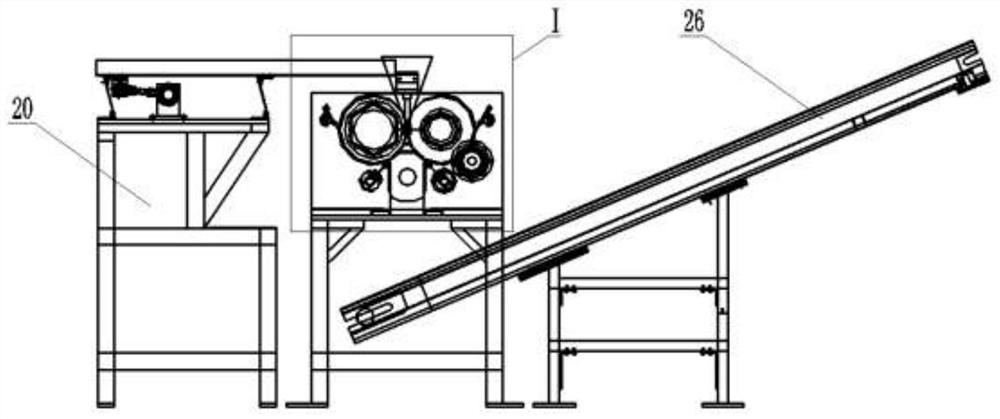

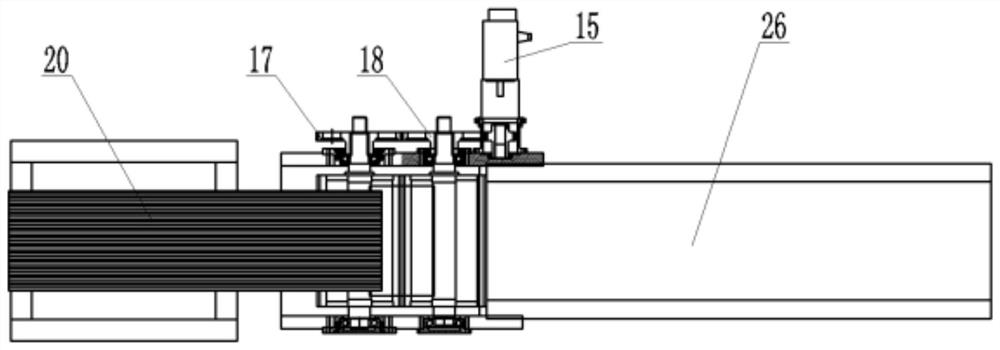

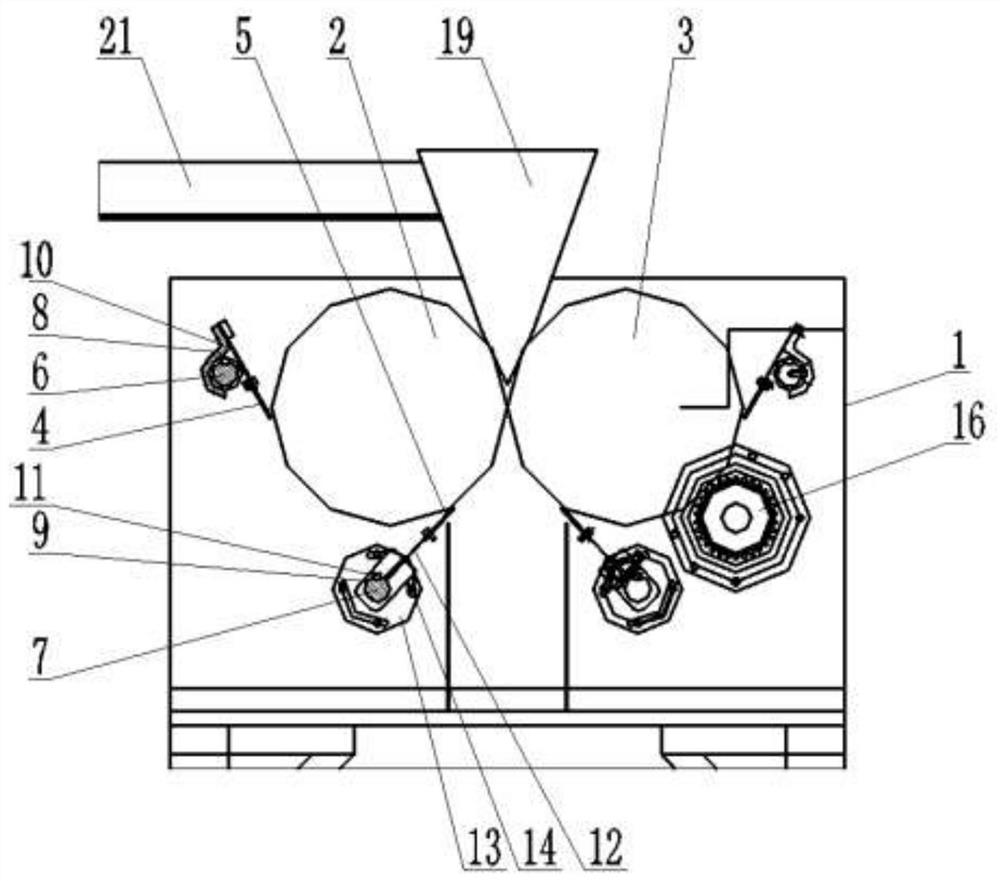

[0020] The invention provides a kind of equipment for pressing tobacco leaf stems into sheets, such as Figure 1 to Figure 4 As shown, it includes support frame 1, pressure roller A2, pressure roller B3, first scraper 4 and second scraper 5, both ends of pressure roller A2 and pressure roller B3 are respectively installed in support frame 1 through rolling bearings, pressure roller A2 The outer peripheral surface and the outer peripheral surface of the pressure roller B3 are circumscribed to each other, and the supporting shaft A6 and the supporting shaft B7 are also fixed in the supporting frame 1, and one side of the first scraper 4 is fixedly connected with the supporting shaft A6 through the first hoop 8, and the second The other side of a scraper 4 leans against the outer peripheral surface of the pressure roller A2 or the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com