Processing device for concave structures on surface of metal pipe

A technology for metal pipes and processing devices, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve problems affecting the dimensional accuracy and shape accuracy of workpieces, difficulty in ensuring processing accuracy and product quality, and deformation of metal pipes under compression , to achieve the effect of ensuring machining accuracy, reducing labor intensity and manual operation error rate, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

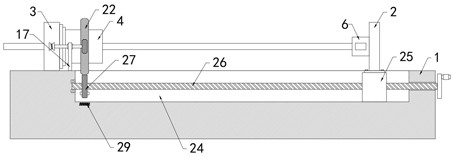

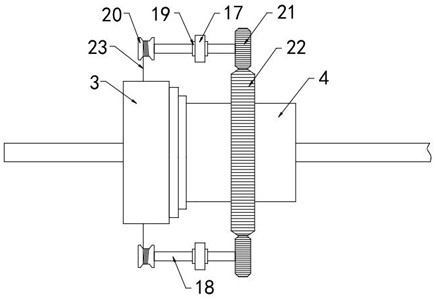

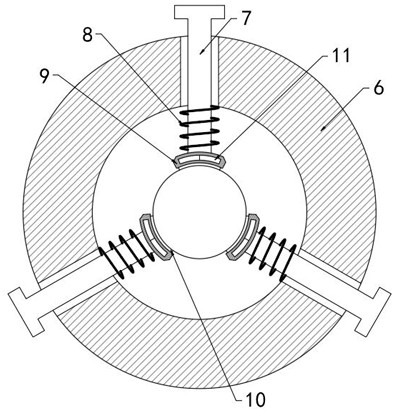

[0028] Such as Figure 1-6 As shown, a processing device for a concave structure on the surface of metal pipes includes a frame 1, on which a mounting plate 2 is slidably arranged, and a fastening mechanism for fixing metal pipes is rotatably provided on the mounting plate 2, the machine A die seat 3 is fixedly arranged on the frame 1, and the middle part of the die seat 3 is provided with a through hole for metal pipe processing. The die seat 3 is provided with multiple sets of die mechanisms for carrying out concave processing of the metal pipe. The side of the die seat 3 A twisting cylinder 4 is rotatably connected to the wall, and the axis of the twisting cylinder 4 is in line with the axis of the through hole. Several conveying rollers 5 are arranged inside the twisting cylinder 4 .

[0029] The fastening mechanism includes a fixed cylinder 6 and multiple sets of clamping parts. In this embodiment, there are three sets of clamping parts, which can ensure that the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com