Protection device of glass kiln charging machine and glass kiln charging machine

A protection device, glass furnace technology, which is applied in the charging of melting furnace, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of aging and damage of accelerating screw, transmission bearing seal, fluctuation of glass liquid level in furnace, affecting glass melting quality and other issues, to achieve the effect of ensuring stability, avoiding long-term high-temperature operation, and reducing the probability of hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

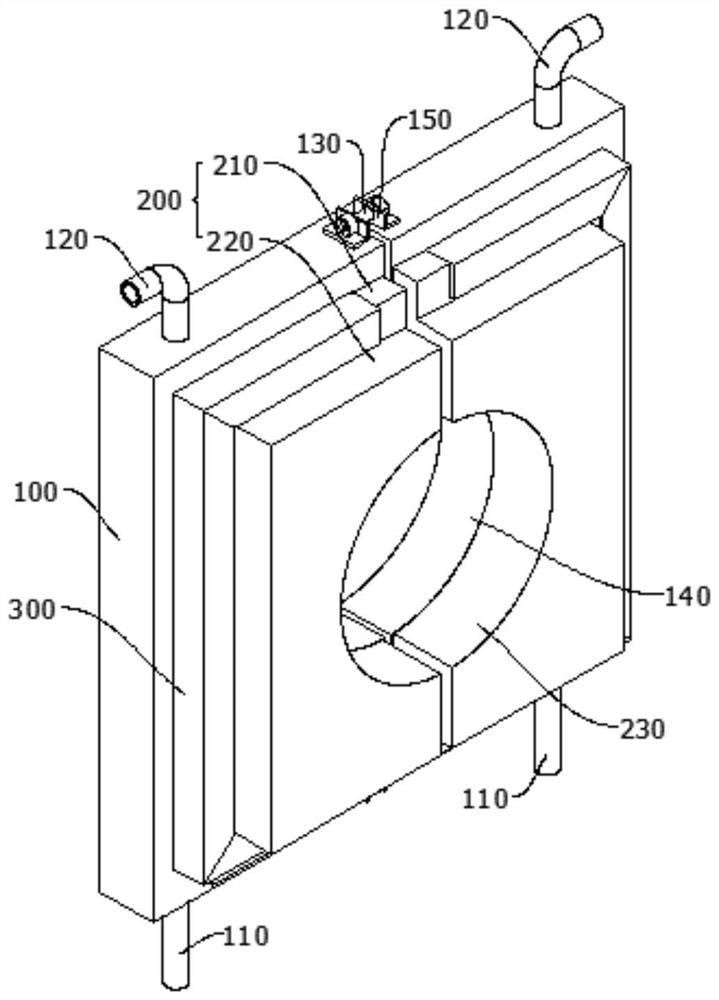

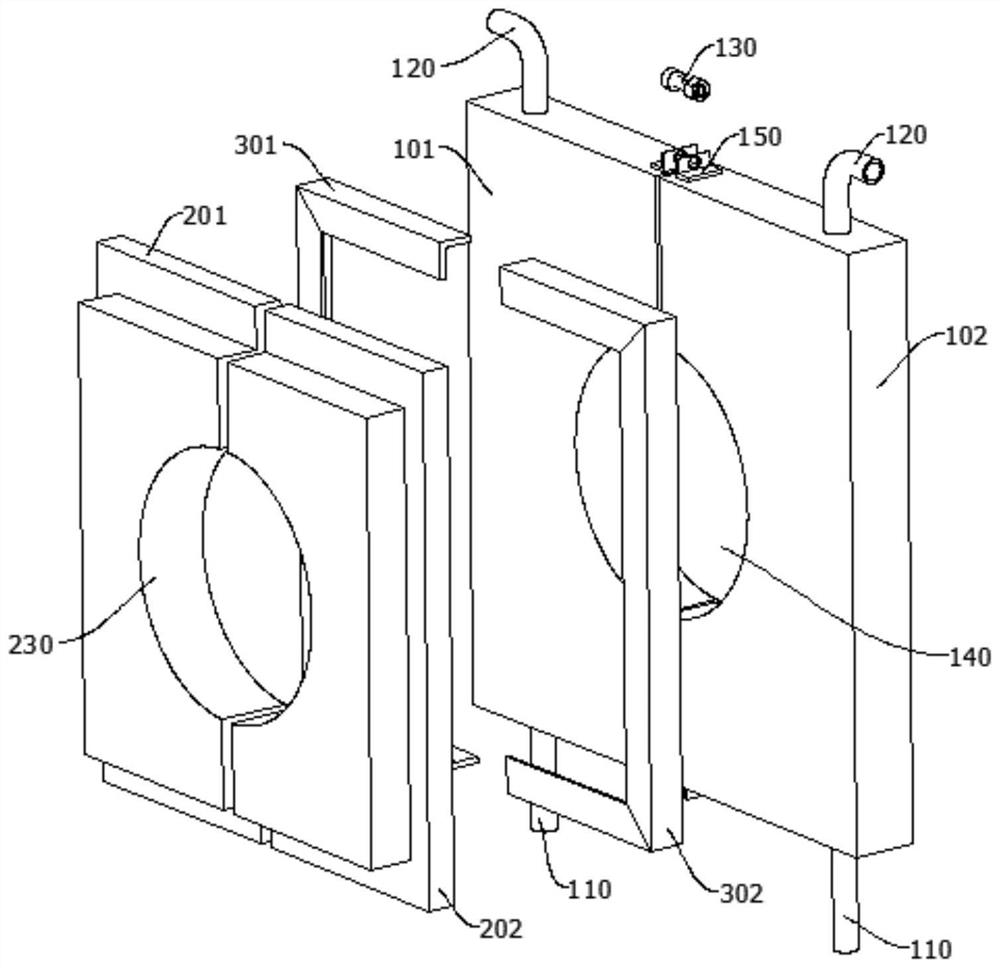

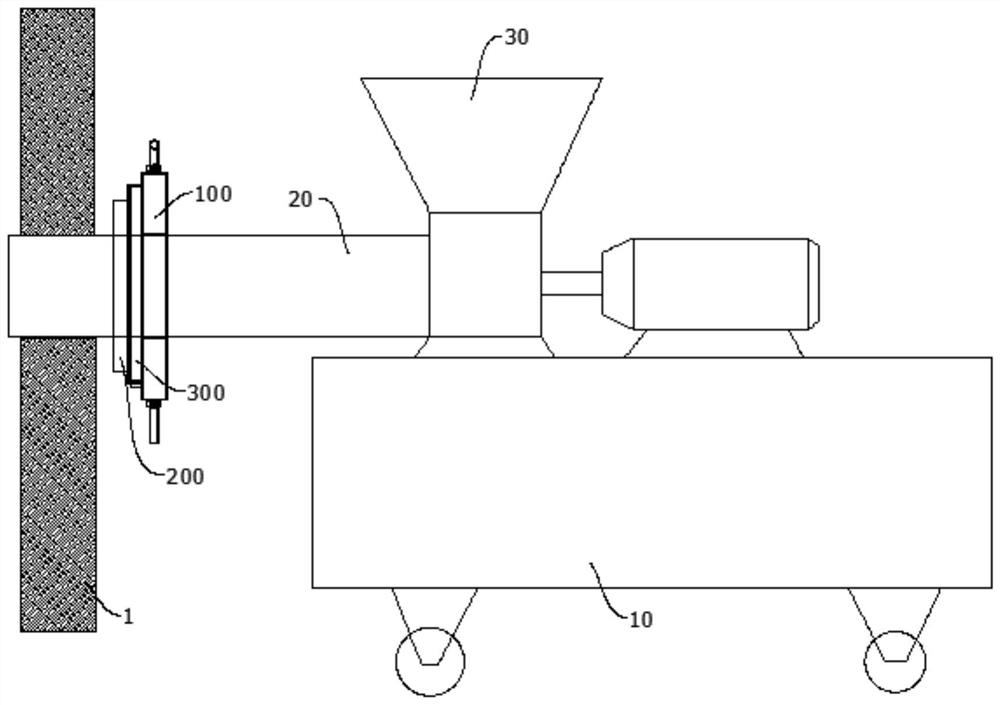

[0022] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0023] In this disclosure, the orientation words used such as "upper", "lower", "top", "bottom", "front", "rear" are according to the glass furnace charging machine unless stated otherwise. The normal use state of the protective device is defined, specifically, the upper and lower top and bottom can refer to image 3 In the direction shown in the drawing, the side of the feeder facing the feeding wall of the glass kiln is the front, and the opposite side is the rear; "inner" and "outer" refer to the contours of the corresponding parts. In addition, the terms "first", "second", and the like used in the present disclosure are for distinguishing one element fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com