Optical performance test line and multi-core optical fiber array connector optical test device

A technology for optical performance testing and connectors, which is applied in testing optical fiber/optical waveguide equipment, measuring devices, optical instrument testing, etc., can solve the problems of low test efficiency of prefabricated terminals, reduce repair and remanufacturing costs, Improve test efficiency and facilitate maintenance of test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

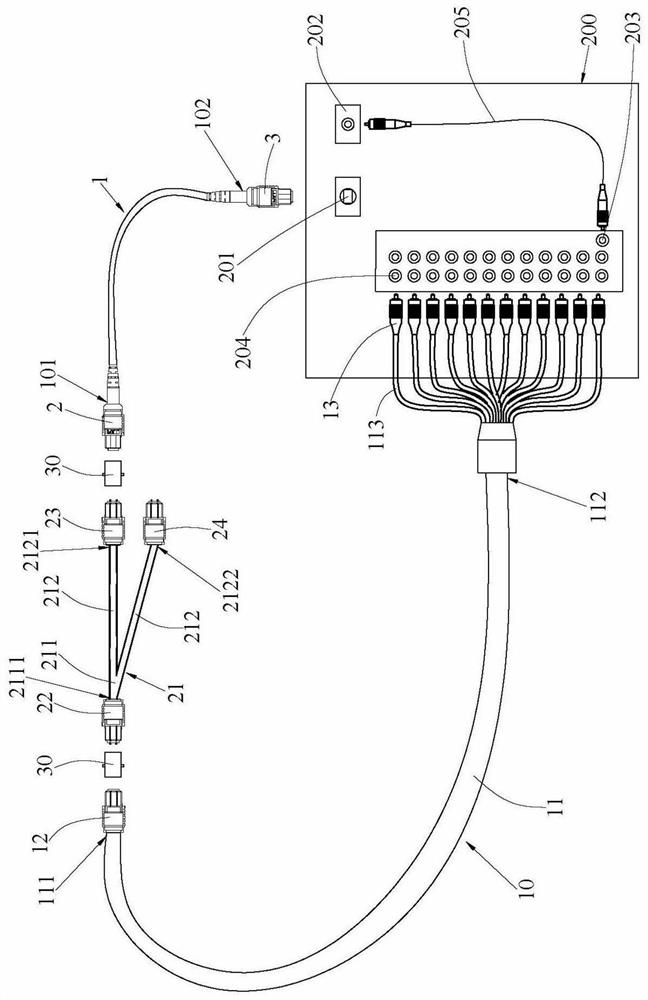

[0018] see figure 1 As shown, the optical performance test line of this embodiment includes a main line assembly 10 and a standard line assembly. The main line assembly 10 includes a main line body 11 with 24 optical cores inside. The host line body 11 is provided with a first A-end 111 and a first B-end 112 along the axial direction. The first B-end 112 fans out 24 branch tail cables 113 , and each branch tail cable 113 has one optical core. Specifically, the first A-end 111 and the first B-end 112 are respectively arranged at both ends of the main line body 11 in the axial direction, and the wire diameter of the branch tail cable 113 is 0.9 mm to reduce the occupation of the branch tail cable 113 for subsequent plugging. space. Prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com