Process industrial process optimization control method considering input constraint and device thereof

A process industry and process optimization technology, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problem of difficult adjustment and control of process industry operating variables, so as to improve resource recovery rate and comprehensive utilization level, strictly Convergence and stability, precise control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

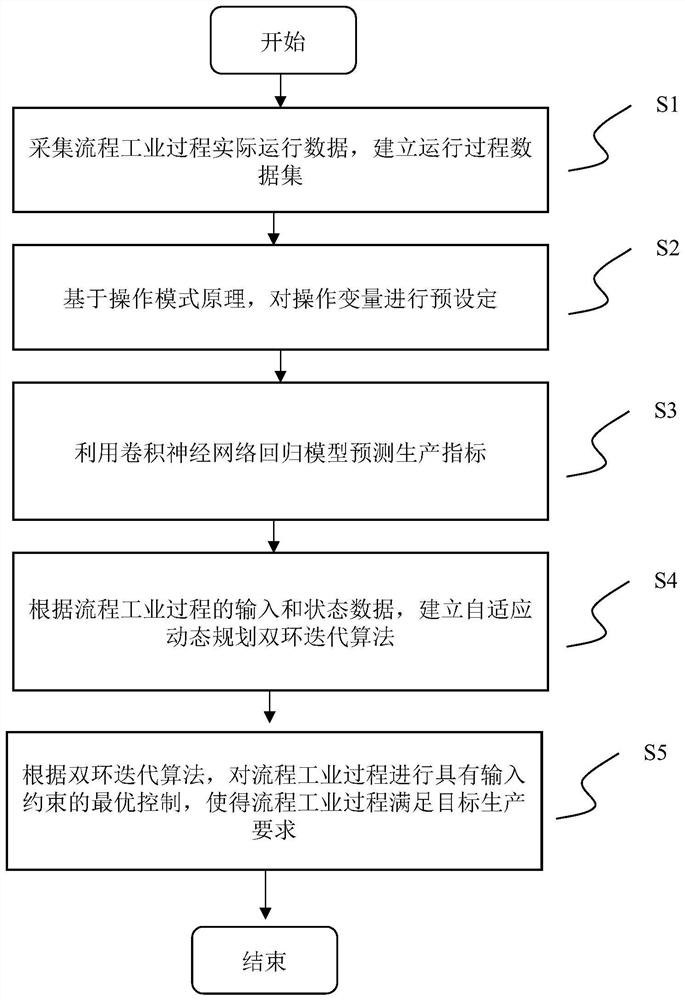

[0238] A kind of flow industry process optimization control method considering input constraints of the present invention is illustrated below with the example of collecting the operating data of a certain sewage treatment process, and the specific steps include:

[0239] Step S1: Collect the actual operating data and corresponding production indicators of the sewage treatment process for 14 days, establish the operating process data set, divide the optimal operating variable sample set into classes through the improved fuzzy C-means clustering algorithm, and then scale and denoise Preprocess the data.

[0240] Step S2, based on the operating mode principle, presetting the operating variable.

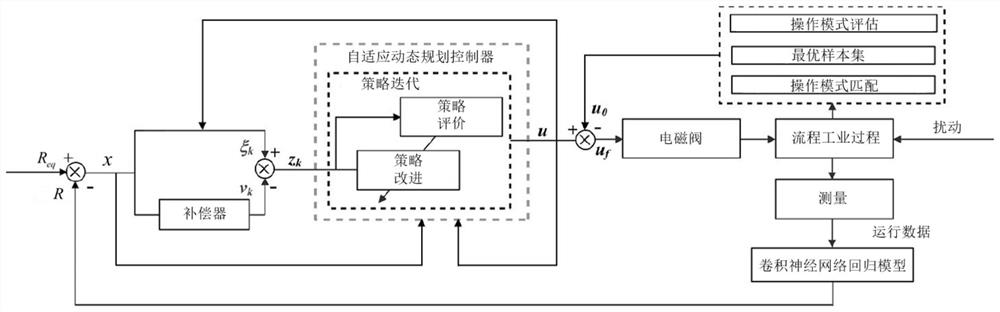

[0241] Build a state-space model of the wastewater treatment process with input constraints:

[0242]

[0243] where x is the system state vector, μ is the control input vector, and σ is the vector value saturation function;

[0244] Use the following formula to match the optimal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com