Ziyan tea wine and preparation method thereof

A technology for violet tea and tea soup, which is applied in the preparation of alcoholic beverages, biochemical equipment and methods, and methods based on microorganisms, etc., can solve the problems of increasing the production cost of raw materials, interference of tea aroma, and being unsuitable for consumers, so as to improve the Bitter taste, strong layering, astringent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

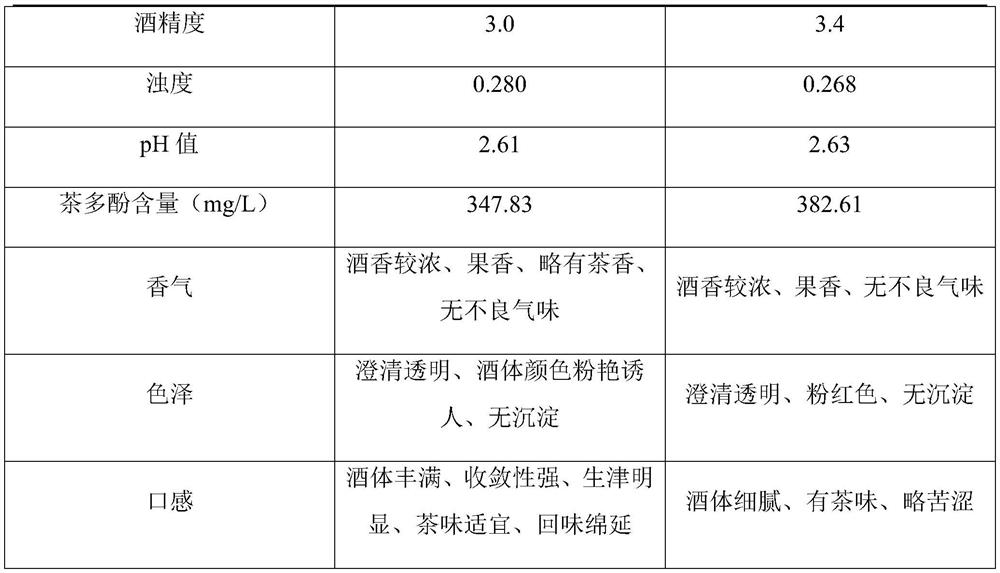

Embodiment 1

[0021] Preparation method of purple tea wine, including:

[0022] (1) Select the spring 1 bud 2 leaf purple tea tree variety fresh leaves as raw materials, according to the killing-rational-dry process, the purple green tea;

[0023] (2) Press tea, water ratio of 1:50 (g / m L) with 85 ° C drinking water to extract tea for 10min, filter to get tea soup ready;

[0024] (3) Tea soup is hot through skimmed cotton filtration, gauze filtration, food grade vacuum pump filtration, cooling after 0.22um filter, sterilization, sterilization tea soup;

[0025] (4) Adding 18% of the mass ratio of sucrose, 3 g / L of ammonium sulfate, 65 mg / L of potassium sulfate and 0.2% volume ratio of brewing yeast, stir the tea soup uniform;

[0026] (5) Two-segment fermentation will be prepared in the formulation of tea soup, including:

[0027] Pre-fermentation: An oxygen fermentation was performed on the fermentation container. At this time, the fermented temperature was 20 ° C until the fermentation ...

Embodiment 2

[0032] Preparation method of purple tea wine, including:

[0033] (1) Select the spring 1 bud 2 leaf purple tea tree variety fresh leaves as raw materials, according to the killing-rational-dry process, the purple green tea;

[0034] (2) Press tea, water ratio of 1:50 (g / m L) with 85 ° C drinking water to extract tea for 10min, filter to get tea soup ready;

[0035] (3) Tea soup is hot through skimmed cotton filtration, gauze filtration, food grade vacuum pump filtration, cooling after 0.22um filter, sterilization, sterilization tea soup;

[0036] (4) Adding 18% of the mass ratio of sucrose, 3 g / L of ammonium sulfate, 50 mg / L of potassium sulfate, and 0.2% by volume ratio of brewing yeast, stir the tea soup uniform;

[0037] (5) Two-segment fermentation will be prepared in the formulation of tea soup, including:

[0038] Pre-fermentation: An oxygen-free fermentation was performed on the fermentation container. At this time, the fermentation temperature was 15 ° C until the s...

Embodiment 3

[0043] Preparation method of purple tea wine, including:

[0044] (1) Select the spring 1 bud 2 leaf purple tea tree variety fresh leaves as raw materials, according to the killing-rational-dry process, the purple green tea;

[0045] (2) Press tea, water ratio of 1:50 (g / m L) with 85 ° C drinking water to extract tea for 10min, filter to get tea soup ready;

[0046] (3) Tea soup is hot through skimmed cotton filtration, gauze filtration, food grade vacuum pump filtration, cooling after 0.22um filter, sterilization, sterilization tea soup;

[0047] (4) Adding 18% mass ratio of sucrose, 3 g / L of ammonium sulfate, 80 mg / L of potassium sulfate and 0.2% volume ratio of Saccharomyces, stir the tea soup uniform;

[0048] (5) Two-segment fermentation will be prepared in the formulation of tea soup, including:

[0049] Pre-fermentation: Oxygen fermentation was performed on the fermentation container, at which time the fermentation temperature was 25 ° C until the surface of the ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com