A circuit board dust removal device for integrated circuit testing

A technology for dust removal equipment and integrated circuits, which is applied in the field of circuit board dust removal equipment for integrated circuit testing, can solve the problems of circuit board equipment operation failure, circuit boards easily attracting dust, and dust cannot be discharged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

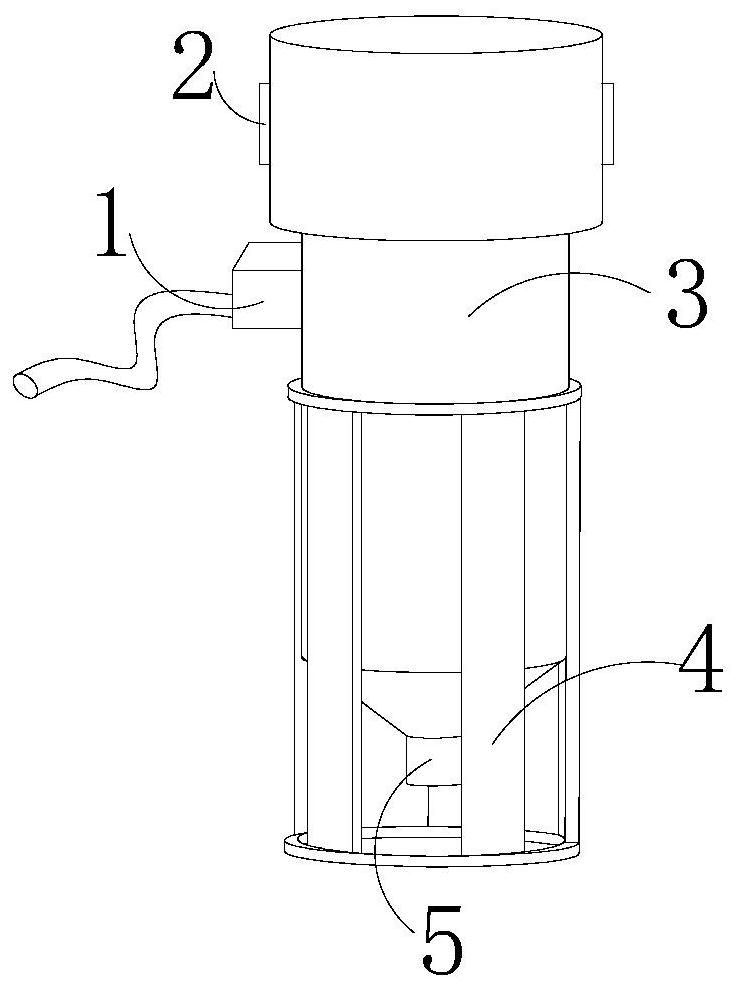

[0022] as attached figure 1 to the attached Figure 4 shown:

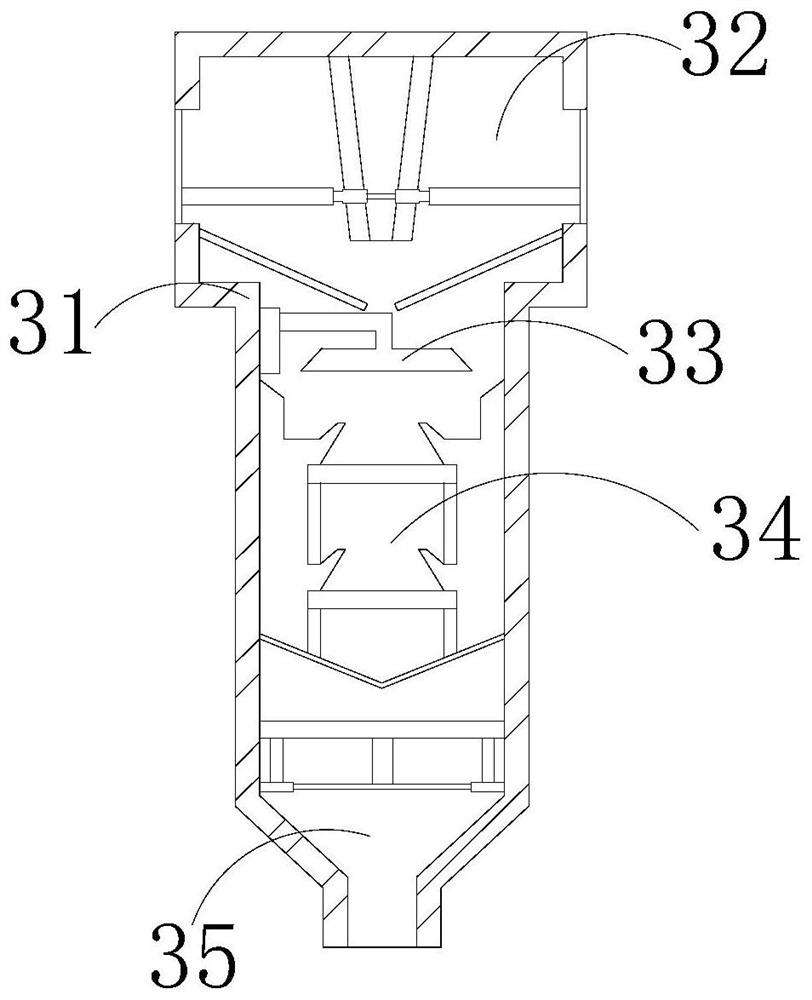

[0023] The present invention is a circuit board dust removal device for integrated circuit testing. The heat dissipation window 2 is fixed on the middle surface of the left end of the processing mechanism 3. The processing mechanism 3 runs through the middle end of the bracket 4. The lower end of the processing mechanism 3 is provided with a dust exhaust port 5. The processing mechanism 3 includes a casing 31, a heat dissipation device 32, an air outlet 33, a dust removal device 34, and a dust drop groove 35. The left end of the air blowing port 33 is connected with the right end of the air pipe 1 , the lower end of the air blowing port 33 is installed with a dust removal device 34 , the upper end of the dust drop groove 35 is installed at the lower end of the dust removal device 34 , and the dust drop groove 35 is installed inside the dust discharge port 5 .

[0024] The heat dissipation device 32 includes a sh...

Embodiment 2

[0029] as attached Figure 5 to the attached Figure 7 shown:

[0030] The dust removal device 34 includes a casing 341, a dust suction port 342, a placing plate 343, a scraping device 344, and a dust removal device 345. The dust suction port 342 is installed on the upper sides of the left and right ends of the placing plate 343, The inner wall of the left and right ends of the casing 341 is provided with a pushing and scraping device 344, and the lower end of the pushing and scraping device 344 is fixedly installed with a ash removal device 345. Both ends of 343 are provided with pushing and scraping devices 344, the upper end of the dust removal device 345 is provided with a placing plate 343, and the upper end of the dust suction port 342 is provided with a dust suction fan, which facilitates the rapid entry of dust on the surface of the circuit board into the dust suction port 342.

[0031]The scraping device 344 includes a scraping brush 44a, a connecting rod 44b, a spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com