Laser etching machine for touch screen processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The following is attached Figure 1-9 The application is described in further detail.

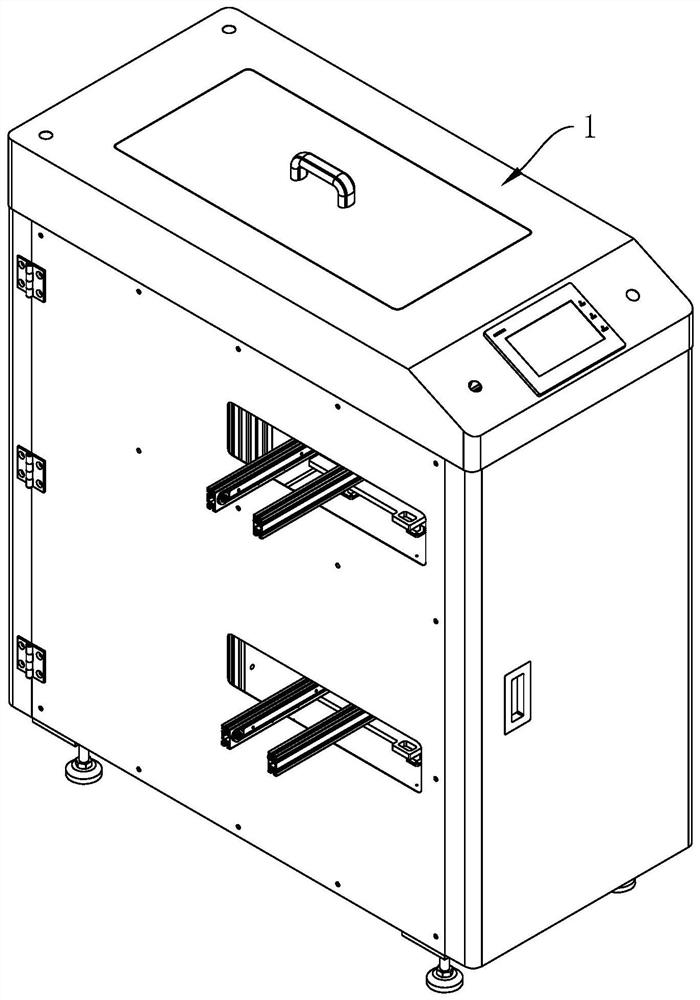

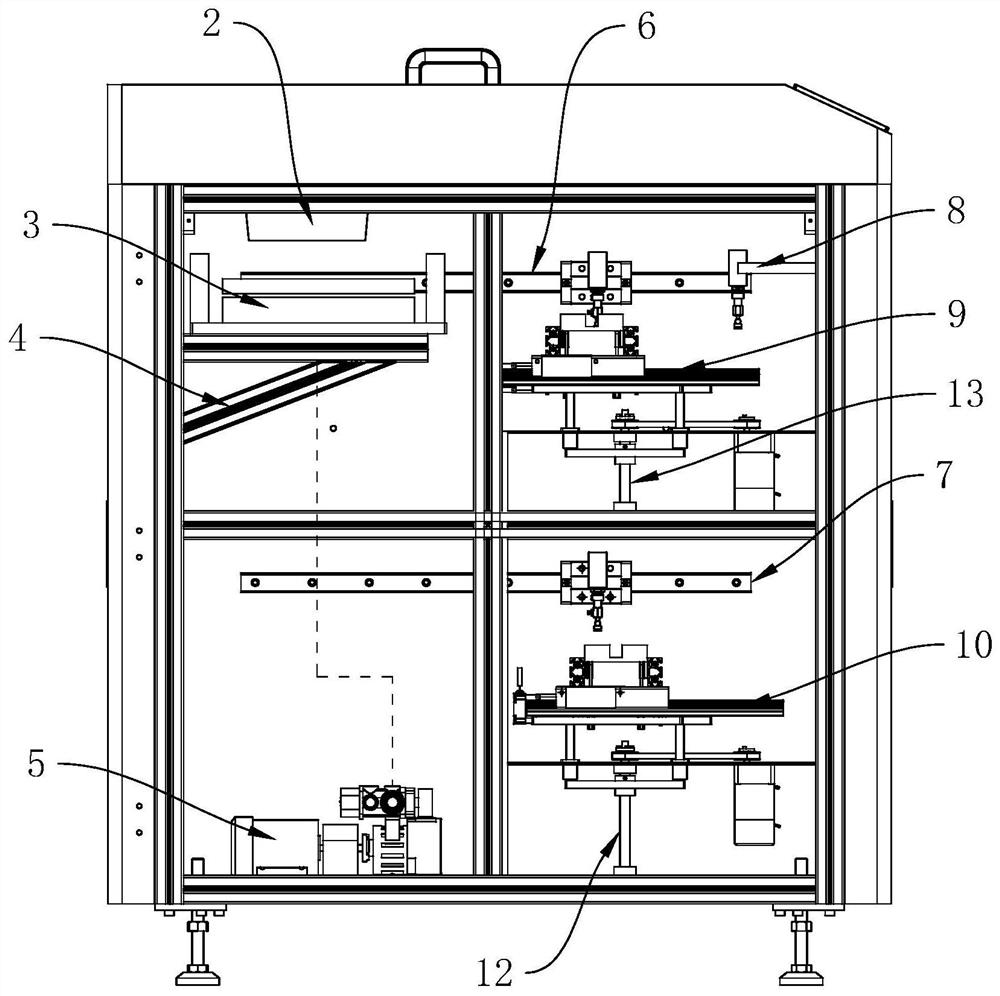

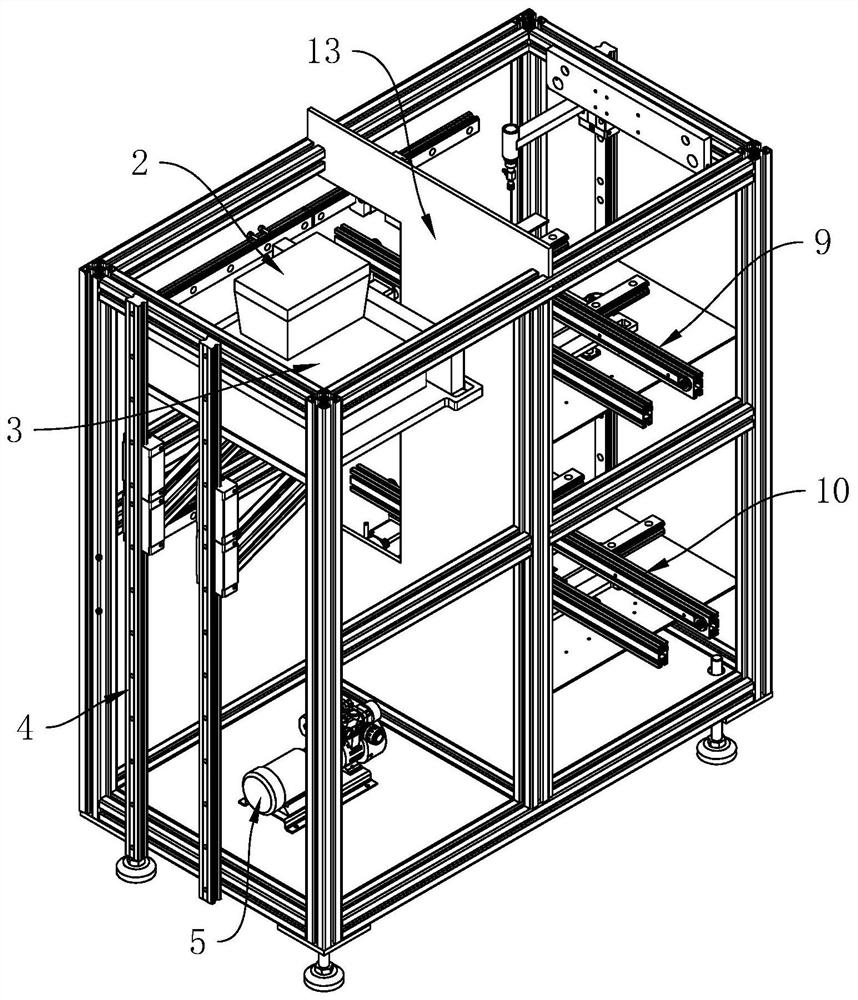

[0061] The embodiment of the present application discloses a laser etching machine for touch screen processing. refer to figure 1 and figure 2 , the laser etching machine includes a frame 1, a high-frequency pulse laser 2, a four-axis high-precision workbench 3, a first elevator 4, an exhaust device 5, a first retrieving device 6, a second retrieving device 7, a third retrieving device material device 8, the first translation assembly 9, the second translation assembly 10 and the lifting assembly; wherein, the inside of the frame 1 passes through a vertical isolation plate 13 ( image 3 (shown in the middle) is divided into an etching area and a transfer area arranged along the length direction of the rack 1, and the transfer area is divided into a feeding area and a discharging area along the height direction of the rack 1.

[0062] refer to figure 2 and image 3 , the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com