A kind of antibacterial coating and preparation method and application thereof

A technology of antibacterial coating and chitosan, applied in the field of antibacterial coating and its preparation, can solve the problems of limited application, unsatisfactory film-forming property and the like, and achieve the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

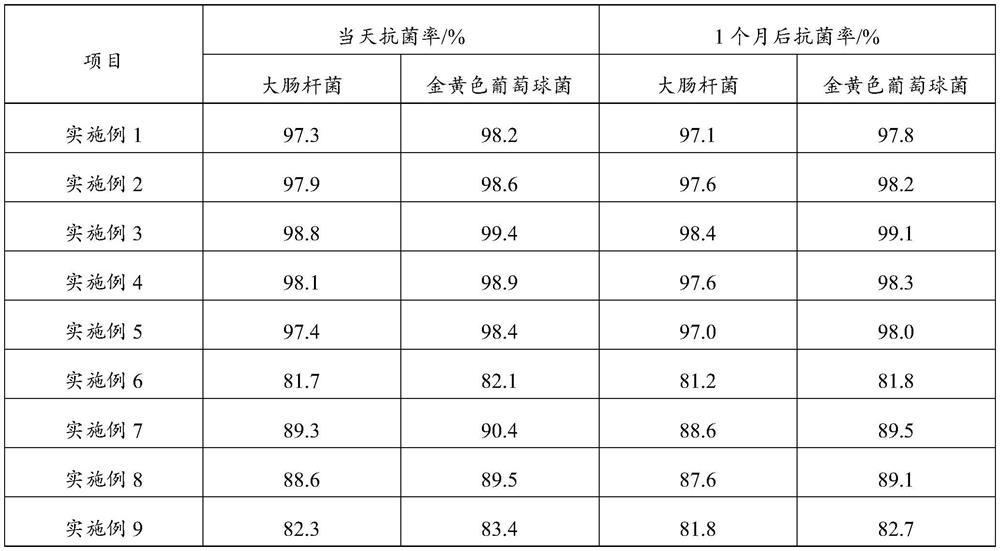

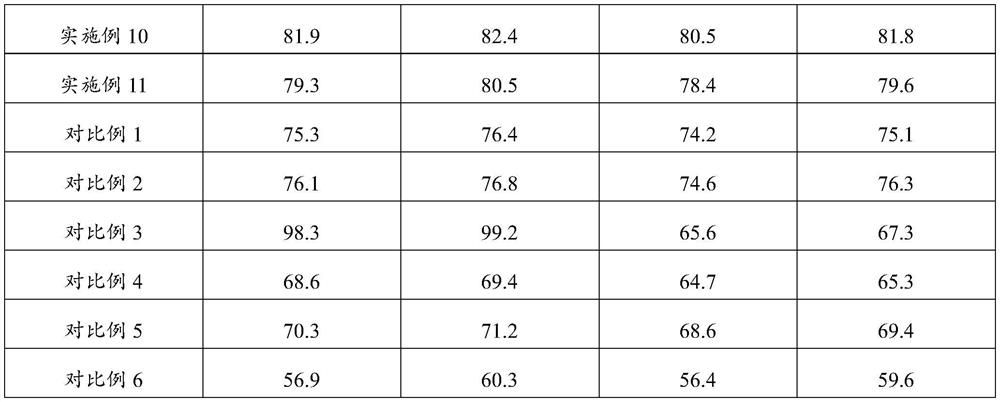

Examples

Embodiment 1

[0036] An embodiment of the antibacterial coating of the present invention, the antibacterial coating of this embodiment is made of the following components by weight: 95 parts of beta-1,4-poly-glucosamine, 5 parts of tannic acid, zinc 0.5 parts of nanoparticles, 0.5 parts of copper nanoparticles, 0.5 parts of sodium cellulose sulfate, 10 parts of ethanol; the preparation method is as follows:

[0037] (1) weigh β-1,4-poly-glucosamine, tannic acid, copper nanoparticles and zinc nanoparticles by mass ratio, put each raw material component into a high-speed mixer for dry mixing, and the mixed The technical parameters of the refining are: the rotating speed is 800r / min, and the time is 4min;

[0038] (2) Weigh sodium cellulose sulfate and n-heptane by mass ratio and add them to the mixer, stir for 20 min at a rotating speed of 600 r / min, then add the material that was uniformly mixed in step (1), and continue at a rotating speed of 400 r / min Stir for 50min to obtain antibacteria...

Embodiment 2

[0041] An embodiment of the antibacterial coating of the present invention, the antibacterial coating of this embodiment is made of the following components by weight: 85 parts of carboxymethyl chitosan, 15 parts of tannic acid, and 1 part of zinc nanoparticles , 1 part of copper nanoparticles, 1.5 parts of sodium cellulose sulfate, 15 parts of n-butanol; its preparation method is as follows:

[0042] (1) weigh carboxymethyl chitosan, tannic acid, copper nanoparticles and zinc nanoparticles by mass ratio, put each raw material component into a high-speed mixer for dry mixing, and the process parameters of the mixing is: the speed is 850r / min, and the time is 5min;

[0043] (2) Weigh sodium cellulose sulfate and n-heptane according to the mass ratio and add them to the mixer, stir for 22 min at a rotating speed of 650 r / min, then add the uniformly mixed material in step (1), and continue at a rotating speed of 450 r / min Stir for 52min to obtain antibacterial coating;

[0044]...

Embodiment 3

[0046] An embodiment of the antibacterial coating of the present invention, the antibacterial coating of this embodiment is made of the following components by weight: 75 parts of β-1,4-poly-glucosamine, 25 parts of tannic acid, zinc 1.5 parts of nanoparticles, 1.5 parts of copper nanoparticles, 2 parts of sodium cellulose sulfate, and 20 parts of phthalates; the preparation method is as follows:

[0047] (1) Weigh β-1,4-poly-glucosamine, tannic acid, copper nanoparticles and zinc nanoparticles by mass ratio, put each raw material component into a high-speed mixer for dry mixing, and the mixed The technical parameters of the refining are: the rotating speed is 900r / min, and the time is 6min;

[0048] (2) weigh sodium cellulose sulfate and n-heptane according to the mass ratio and add them to the mixer, stir for 24min at a rotating speed of 700r / min, then add the material mixed in step (1), continue at a rotating speed of 500r / min Stir for 54min to obtain antibacterial coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com