Self-rotation type outer rotor asynchronous electric heating assembly and drying equipment

An external rotor, self-rotating technology, applied in lighting and heating equipment, drying, dryers, etc., can solve the problems of downtime maintenance, complex structure, comprehensive comparison of energy consumption, and achieve the effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

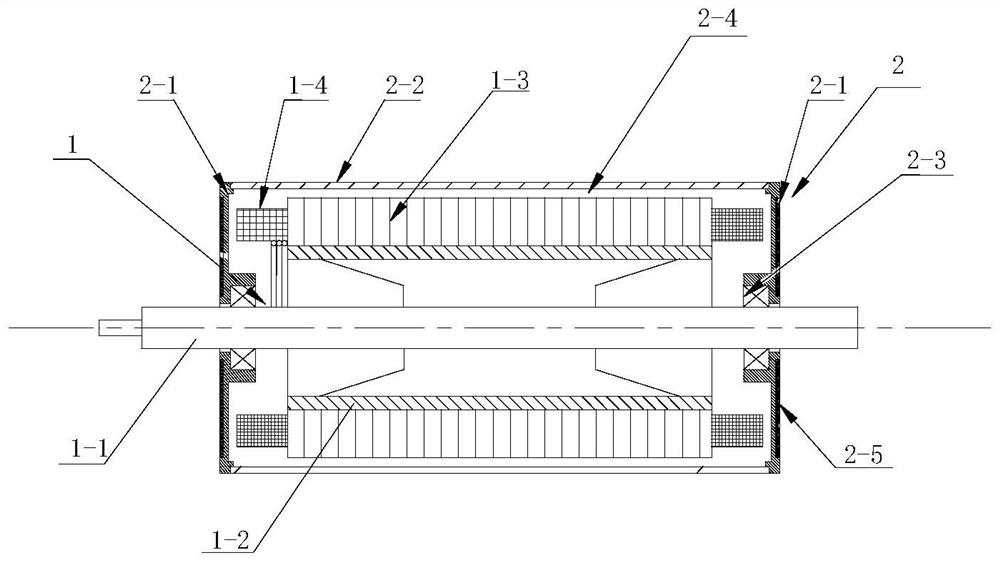

[0033] Embodiment 1, preferably, the core support is an integrated structure, please refer to figure 1 ; The axial length of the iron core is longer and the power is larger, which is suitable for occasions with large heat demand.

Embodiment 2

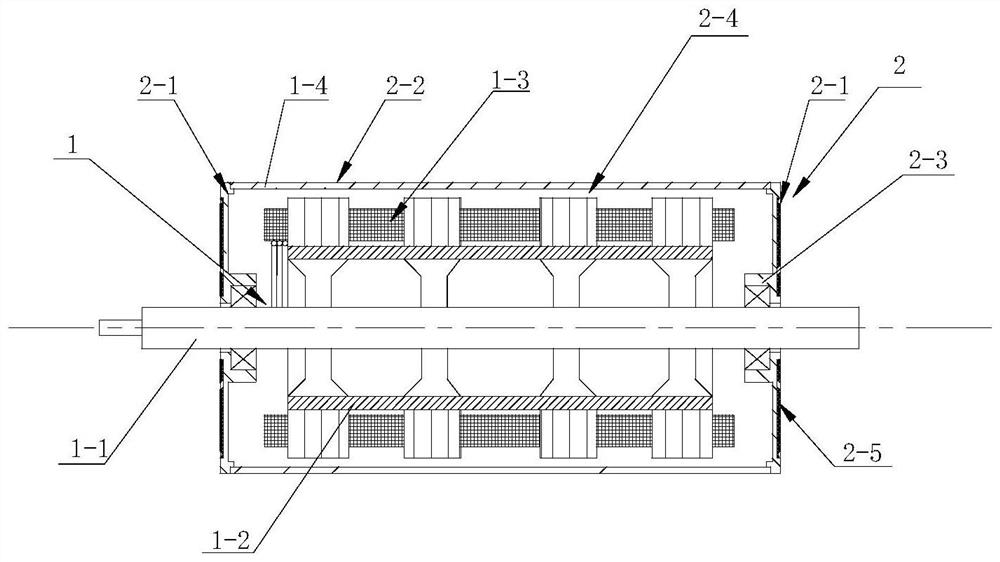

[0034] Embodiment 2, preferably, the core adopts a segmented structure, please refer to figure 2 , the driving winding and the heating winding are continuous, when the demand for heat generation is small. Since the length of the rotor cylinder is determined according to the object to be dried, the iron core is segmented to reduce part of the iron core to reduce the consumption of iron core materials.

Embodiment 3

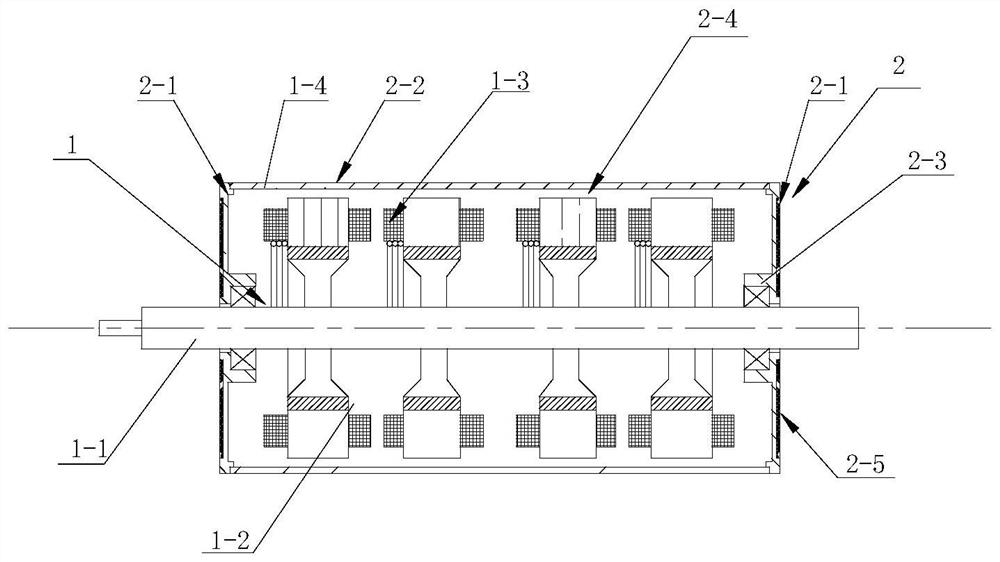

[0035] Embodiment 3, preferably, the core support is a split structure, please refer to image 3 , each core bracket is equipped with an iron core, and the winding on each iron core is independent. This situation also reduces the amount of iron core. Due to the existence of the winding end, the distance between the iron core segments needs to meet the requirements of the end length. However, each core segment and winding can be manufactured separately to form modules, and different numbers of modules can be assembled according to design requirements, which is conducive to standardized and generalized production.

[0036] Preferably, the gap between the outer wall of the iron core and the inner wall of the rotor cylinder is 0.5mm-7.5mm. If the gap is too small, the machining requirements are high, the processing is difficult, and mechanical failures are prone to occur during operation; if the gap is too large, the reluctance of the gap is too large. Larger current is required t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com