Method for predicting octane number of gasoline

A gasoline octane number and prediction method technology, which is applied to the processing of hydrocarbon oil, measuring devices, and the petroleum industry, can solve problems such as high cost, strict experimental conditions for octane number measurement, and difficult experiments, and achieve easy calculation and calculation The effect of high precision and simple calculation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

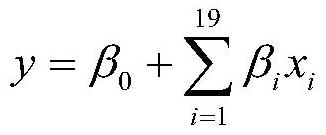

Method used

Image

Examples

specific Embodiment

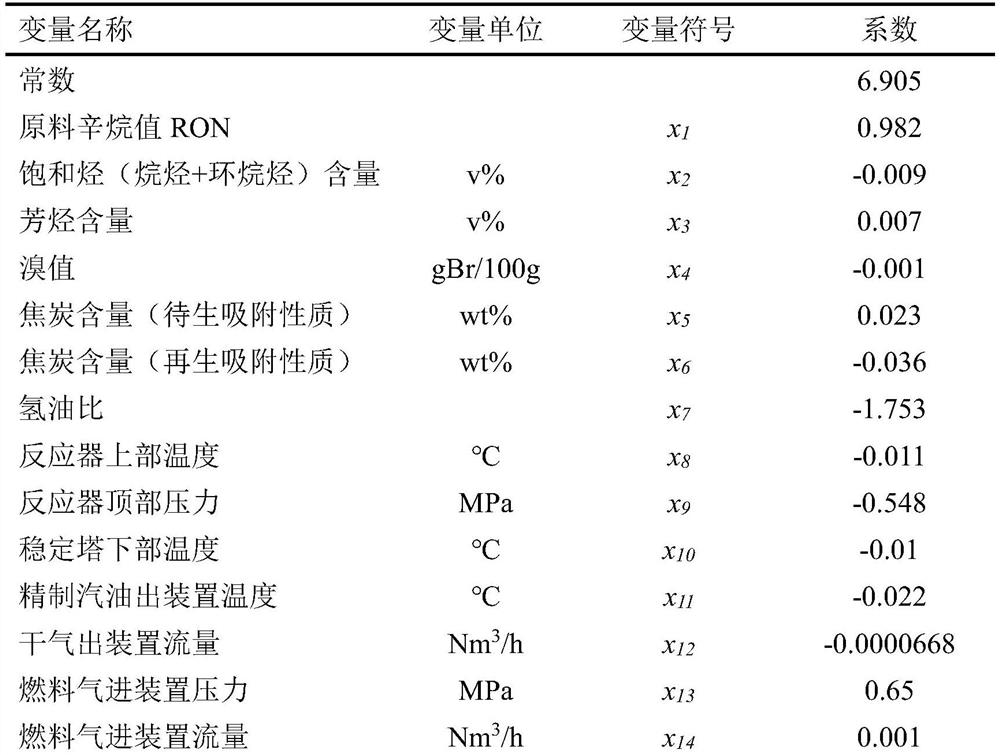

[0028] A large amount of data accumulated in the long-term operation of the catalytic cracking gasoline refined desulfurization unit of a petrochemical company. Now predict the gasoline octane number according to the inventive method, and implementation steps are as follows:

[0029] Step 1, collect sample data in the catalytic cracking gasoline refining desulfurization unit, including raw material octane number RON, saturated hydrocarbon (alkane + cycloalkane) content, aromatics content, bromine value, coke content (dead adsorption properties), coke content ( regenerative adsorption properties), hydrogen-oil ratio, reactor upper temperature, reactor top pressure, stabilizer lower temperature, refined gasoline outlet temperature, dry gas outlet flow, fuel gas inlet pressure, fuel gas inlet flow, steam inlet The temperature of the device, the flow rate of catalytic gasoline into the device, the flow rate of raw materials into the device, the liquid level of the condensate tank,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com