Electrical control circuit for main motor of circulating cableway dragged by diesel generator

A diesel generator and electrical control technology, which is applied in motor generator control, AC motor control, and four-quadrant motor control, etc., can solve the problems of not allowing the use of two-quadrant frequency converters, inability to consume, and uncontrollable energy. Achieve good monitoring and protection control, realize the effect of stall protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

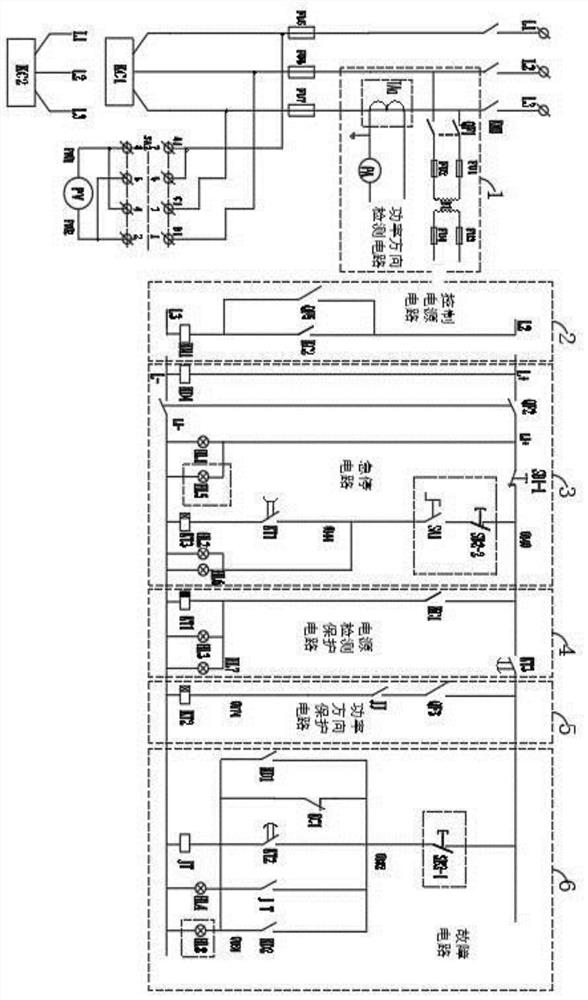

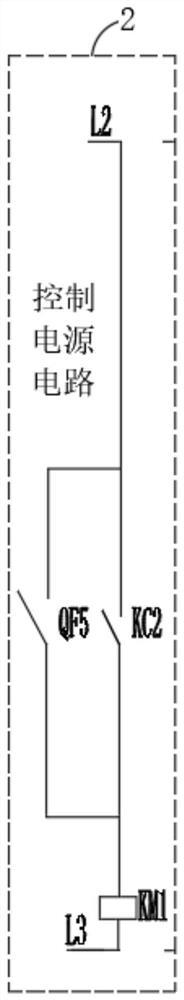

[0049] see Figure 1-10 , the electrical control circuit of the main motor of the diesel generator dragging the circulating cableway, including:

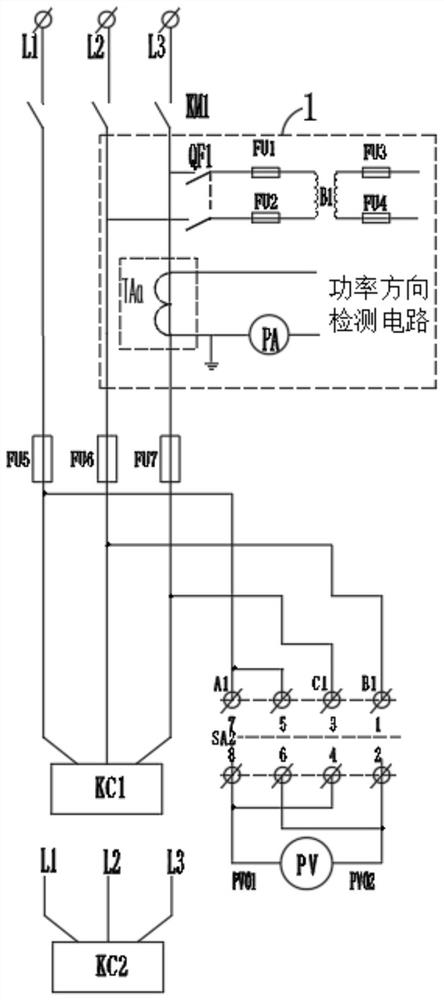

[0050] Three-phase intelligent monitoring phase loss, overvoltage and undervoltage relay KC1 and inverter INV, the L1 terminal, L2 terminal and L3 terminal of the overvoltage and undervoltage relay KC1 are respectively connected with fuse FU5, fuse FU6 and fuse FU7, and the overvoltage and undervoltage The terminals L1, L2 and L3 of the relay KC1 are all connected to a voltmeter PV;

[0051] Power direction detection circuit 1, the input end of power direction detection circuit 1 is connected to the output ends of fuse FU6 and fuse FU7, specifically: power direction detection circuit 1 includes current transformer TAa, ammeter PA, circuit breaker QF1, fuse FU1, fuse FU2, fuse FU3 and fuse FU4, there are two circuit breakers QF1, the input terminals of the two circuit breakers QF1 are respectively connected with the output terminals...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap