PCB with screw through hole stress buffering and aligning device and processing method

A PCB board and buffer device technology, which is applied in the structural connection of printed circuits, printed circuit components, printed circuits, etc., can solve problems such as tin cracking, screw offset scratching PCB board circuits, failure, etc., to avoid tin cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

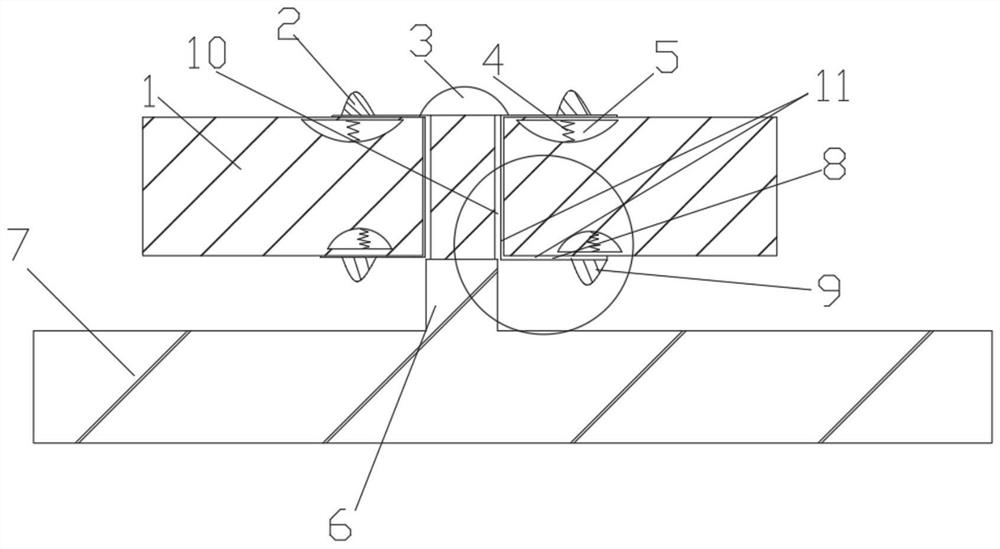

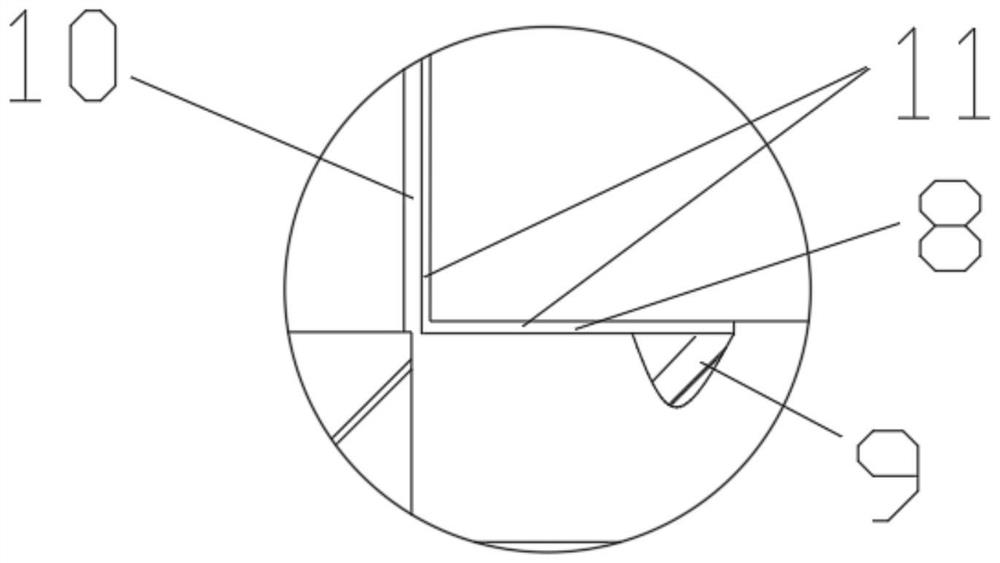

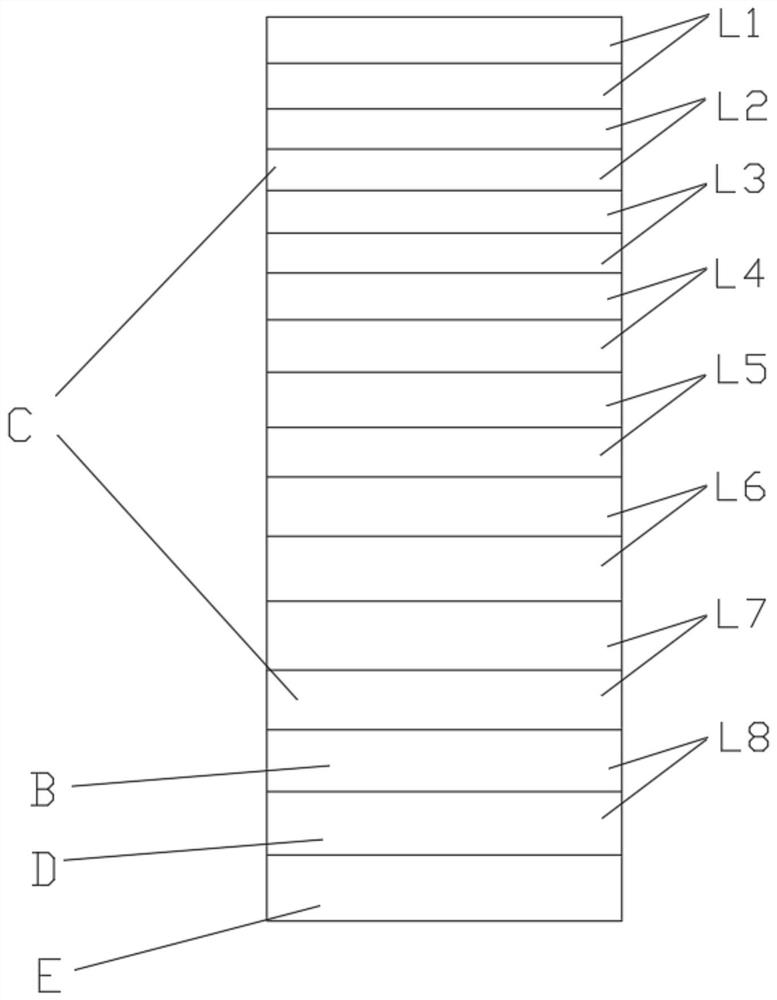

[0029] Embodiment 1: as figure 2 Shown: the PCB main body 1 has 8 layers, and the 8 layers are respectively marked as L1-L8 layers from top to bottom, where L2 and L7 are signal return layers, and the PCB main body 1 is provided with screws Through hole 10, through screw 3 in described screw through hole 10, the periphery of described screw through hole 10 is provided with Pad11, described Pad11 (in the main body of PCB board, Pad is the meaning of pad, is the main body of PCB board and components and parts leads The part where the feet are welded to each other is composed of copper foil and holes. The copper foil should be exposed and should not be covered by solder mask) The size and shape should be set according to the position of the wave soldering component, and the pad around the screw through hole 10 and adjacent to the wave soldering A restricted area is set between the pins of the component, and the screw through hole is avoided in the restricted area. A circle of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com