Rubber molded body and battery pack

A technology of rubber molding and silicone rubber composition, which is applied to battery pack parts, secondary batteries, battery covers/end covers, etc., can solve problems such as extended burning, battery burnout, and thermal runaway of lithium-ion secondary batteries, etc., to achieve Effects of suppressing overheating and suppressing flame spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the present invention will be described in detail.

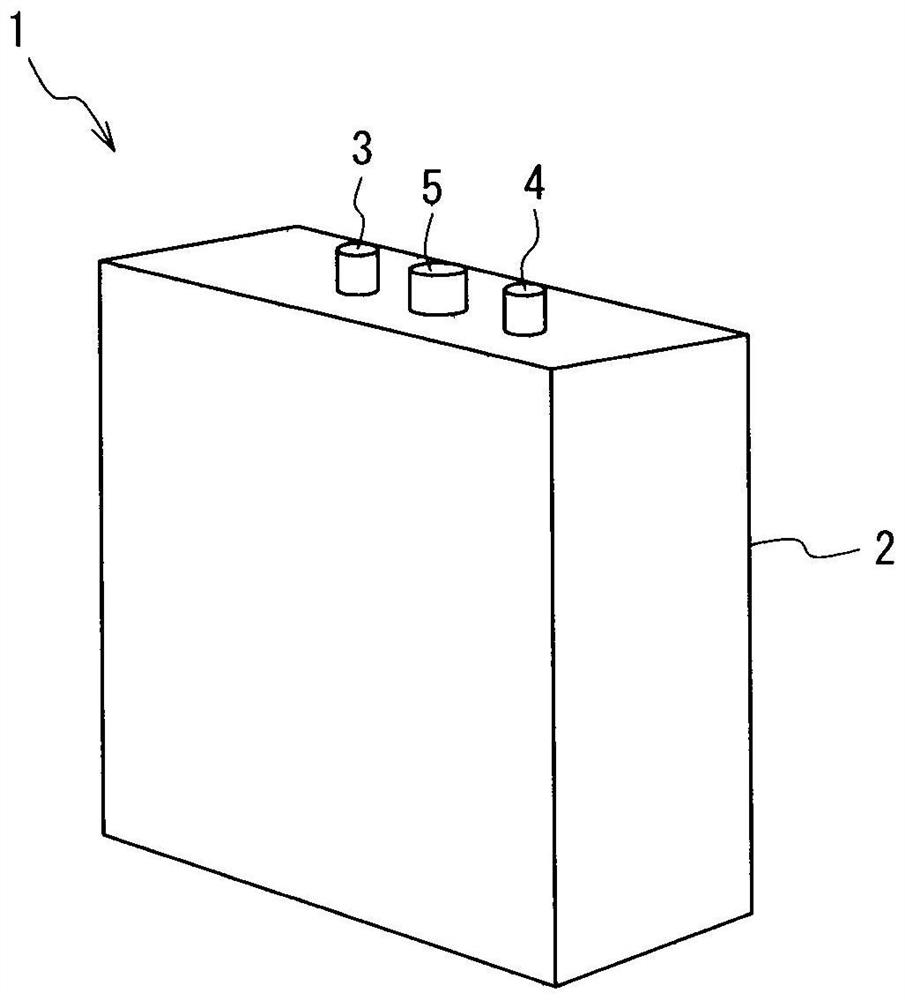

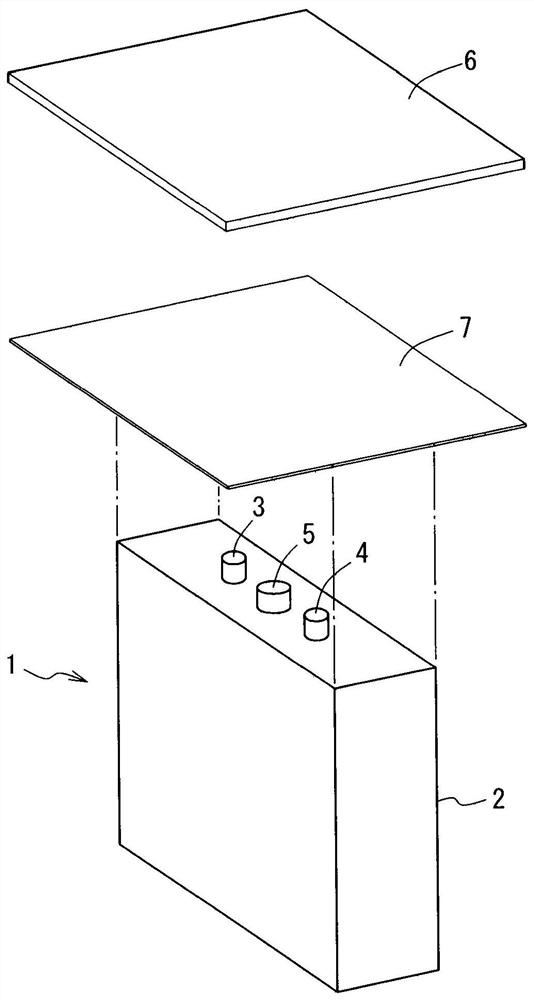

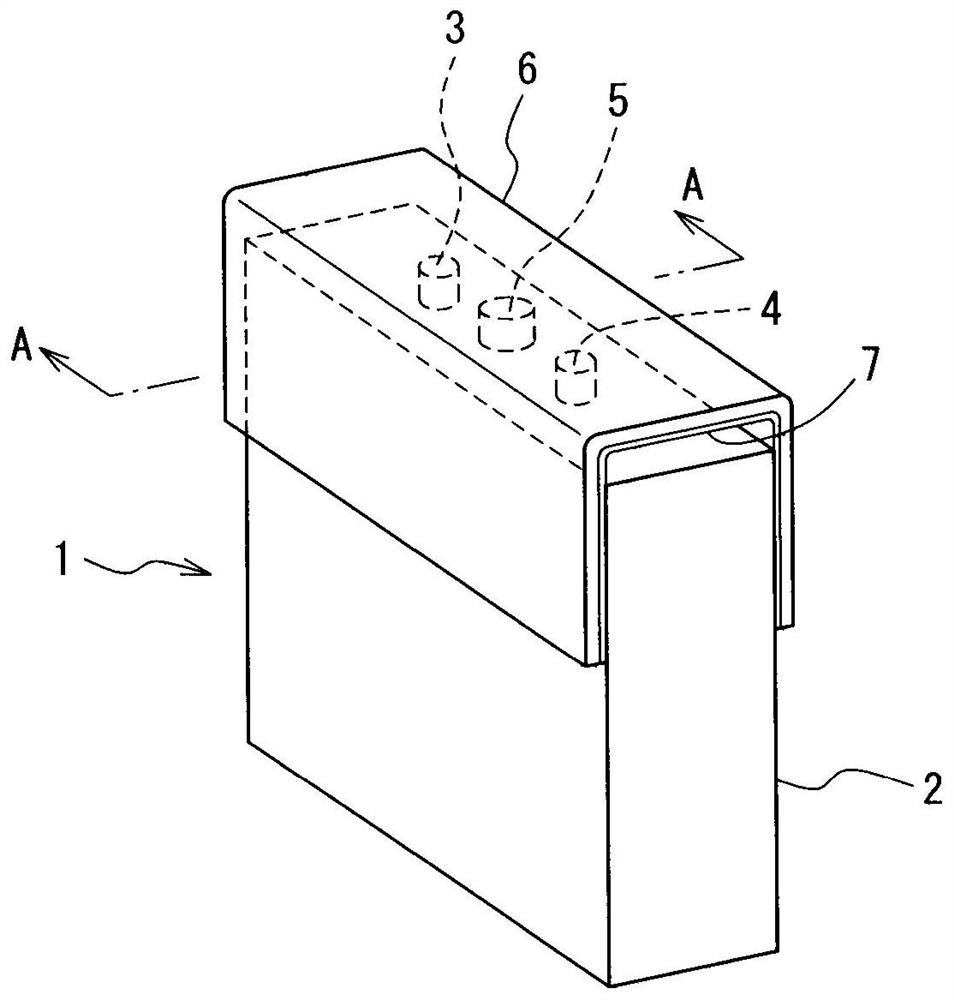

[0041] figure 1 It is a perspective view of a lithium ion secondary battery cell provided with a rubber molded body according to an embodiment of the present invention.

[0042] The lithium-ion secondary battery core 1 is a square-shaped battery core, and a positive terminal 3 and a negative terminal 4 are provided on the upper surface of a packaging can 2 as a battery container, and a safety valve 5 is provided therebetween.

[0043] When the internal pressure rises due to thermal runaway of the lithium-ion secondary battery cell 1 , the safety valve 5 operates to prevent the high-temperature / high-pressure gas from blowing out and causing the packaging can 2 to rupture.

[0044] In the case of thermal runaway of the lithium-ion secondary battery cell 1, there is a risk of ignition due to overheating, and if the high-temperature / high-pressure gas ejected from the safety valve 5 spreads ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com