Overhead modular deodorization device for tunnel fermentation bin

A fermentation bin and modular technology, applied in the field of modular deodorization devices, can solve the problems of different odor concentration and corrosiveness, high energy consumption, and poor horizontal collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

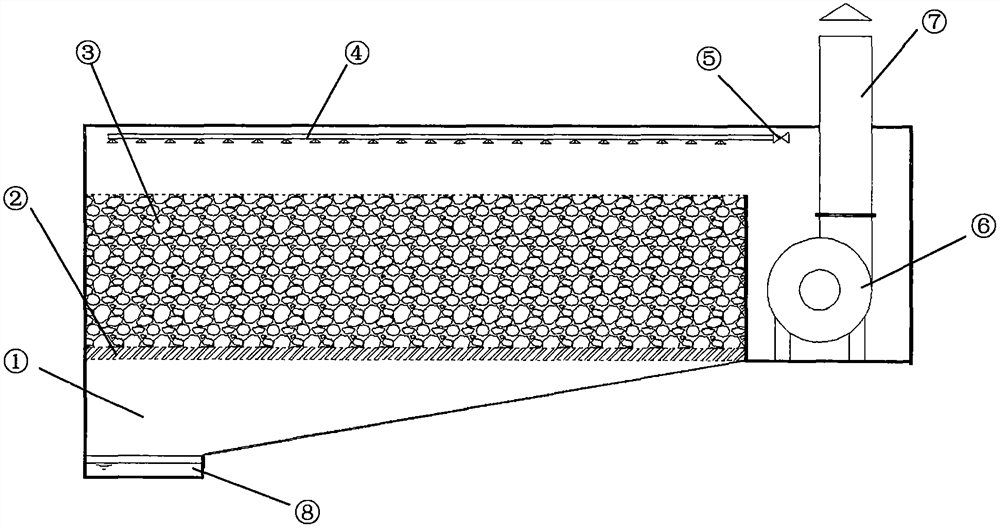

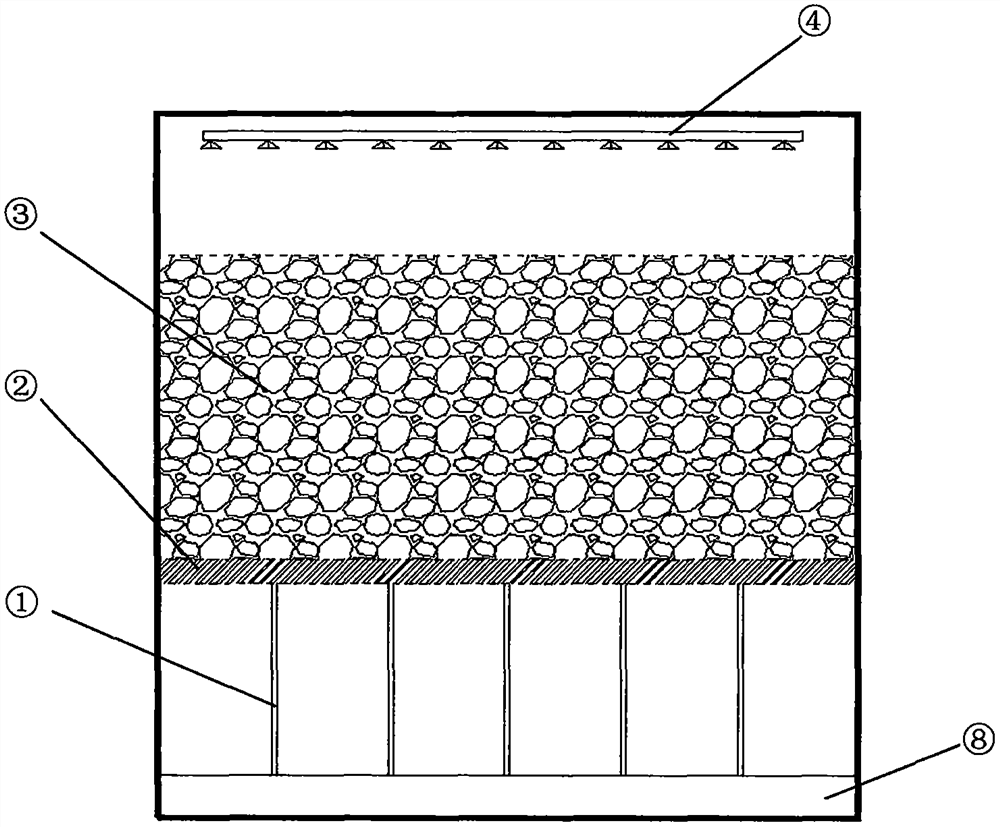

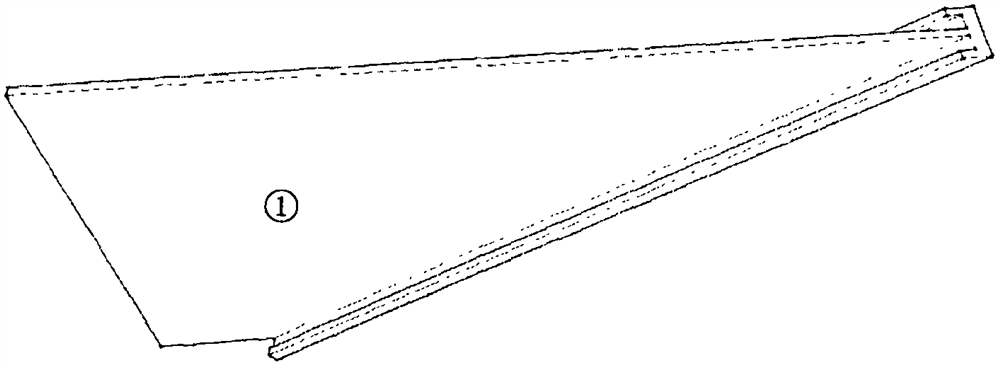

[0027] Such as figure 1 , 2 , 3, and 4, a top-mounted modular deodorization device for tunnel fermentation bins includes: double diversion support plate 1, support layer 2, filler 3, spray device 4, spray control valve 5, Fan 6, exhaust cylinder 7, condensed water collection tank 8.

[0028] According to the structural characteristics of the tunnel-type tunnel fermentation bin, the odor generated in the bin is concentrated on the top of the tunnel fermentation bin and flows autonomously towards the end of the bin; n groups of modular deodorization devices are installed on the top of a tunnel-type tunnel fermentation bin, n=1~ 100; wherein the double diversion support plate 1 is embedded inside the tunnel fermentation chamber 9, the odor passes through the double diversion support plate 1 and the supporting layer 2 under negative pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com