Rust removal robot based on ultrahigh pressure water

An ultra-high pressure and robotic technology, applied in the field of robotics, can solve problems such as affecting the appearance, low efficiency of rust removal, and limited spray area of the nozzle, so as to improve safety, efficiency, rust removal effect and gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

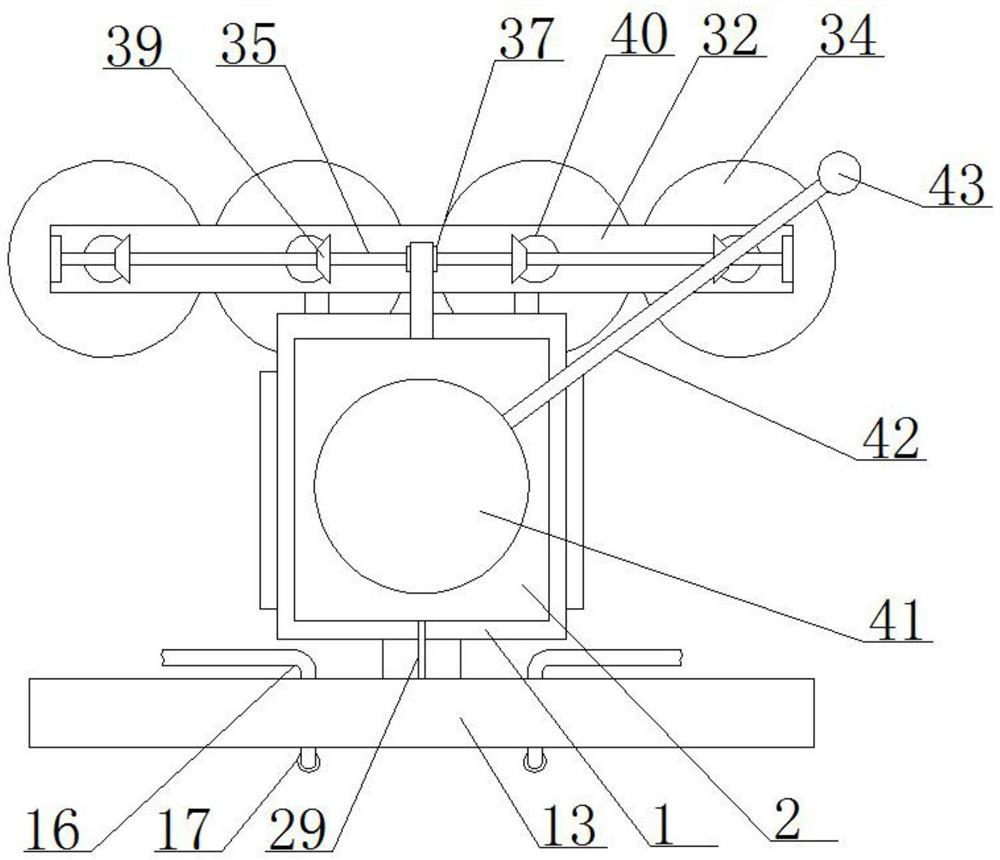

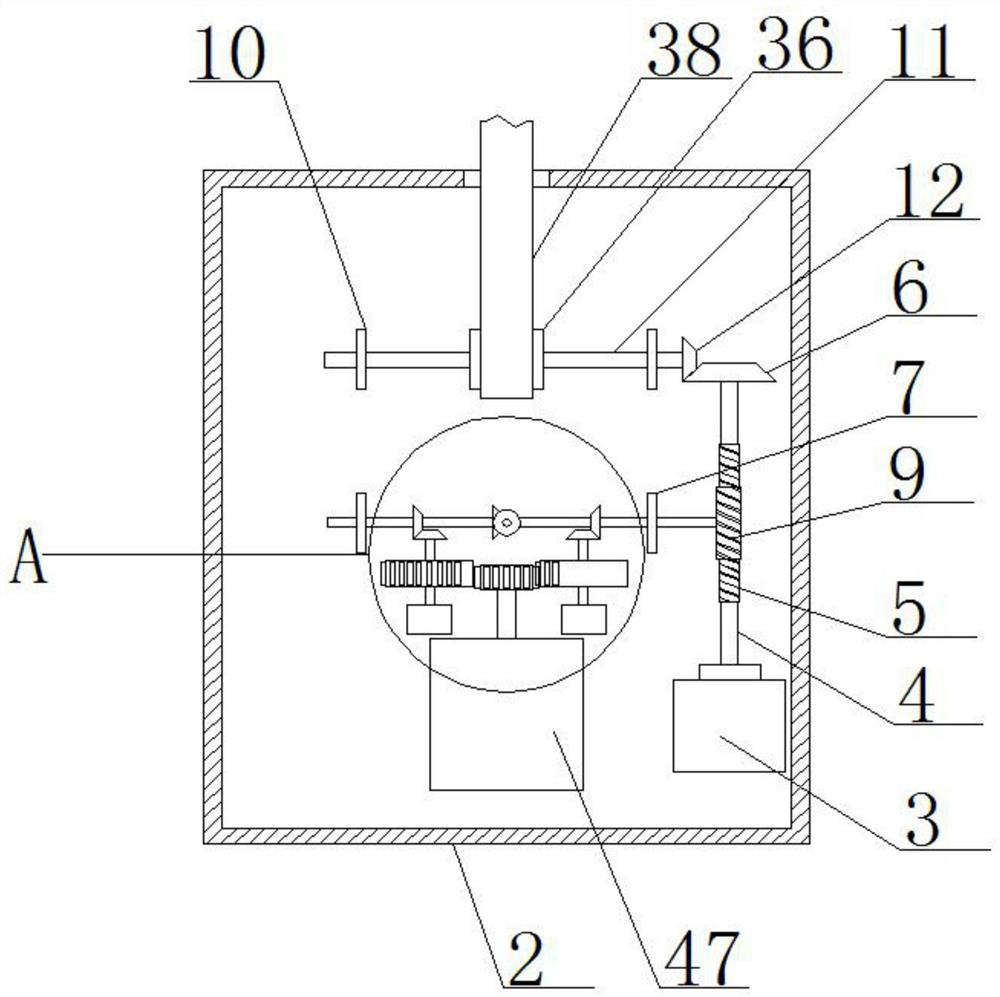

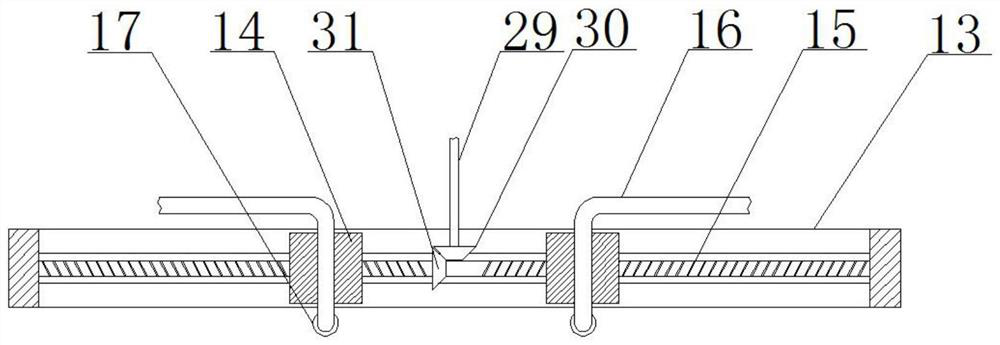

[0030] refer to Figure 1-6 , a rust removal robot based on ultra-high pressure water, comprising a mobile robot main body 1, the top of the mobile robot main body 1 is fixedly connected with a protective shell 2 by bolts, and a motor 3 is fixedly installed in the protective shell 2 by bolts, and the mobile robot main body The front end of 1 is provided with a high-pressure water derusting mechanism, the rear end of the main body of the mobile robot 1 is provided with a polishing mechanism, the top of the protective shell 1 is provided with an ultrasonic radar navigation mechanism, and the motor 3 is connected with the high-pressure water derusting mechanism, polishing mechanism and ultrasonic radar. In cooperation with the navigation mechanism, the output shaft of the motor 3 is welded with a first rotating shaft 4, the outer side of the first rotating shaft 4 is provided with a worm screw 5 through a welding fixed sleeve, and one end of the first rotating shaft 4 is fixedly c...

Embodiment 2

[0042] The difference from Embodiment 1 is that it includes a mobile robot main body 1, a protective housing 2 is fixedly connected to the top of the mobile robot main body 1, a motor 3 is fixedly installed in the protective housing 2, and a high-voltage The water derusting mechanism, the rear end of the main body 1 of the mobile robot is provided with a polishing mechanism, the top of the protective shell 1 is provided with an ultrasonic radar navigation mechanism, and the motor 3 cooperates with the high-pressure water derusting mechanism, the polishing mechanism and the ultrasonic radar navigation mechanism. The output shaft of 3 is welded with a first rotating shaft 4, the outer fixed sleeve of the first rotating shaft 4 is provided with a second small bevel gear, and one end of the first rotating shaft 4 is fixedly connected with a large bevel gear 6, and the protective shell 2 Two first bearings 7 are arranged inside, and the same first rotating rod 8 is arranged on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com