Biomedical NiTiFe-Ta composite board and preparation method thereof

A biomedical and composite plate technology, applied in the field of biomedical composite materials, can solve the problems that cannot be fully satisfied, and achieve the effect of excellent biocompatibility, high bonding strength, and uniform surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation operation of the present embodiment comprises the following steps:

[0036] (1) Selection of raw materials, including:

[0037] Outer layer material: select high-purity Ta (Ta content is 99.96wt.%);

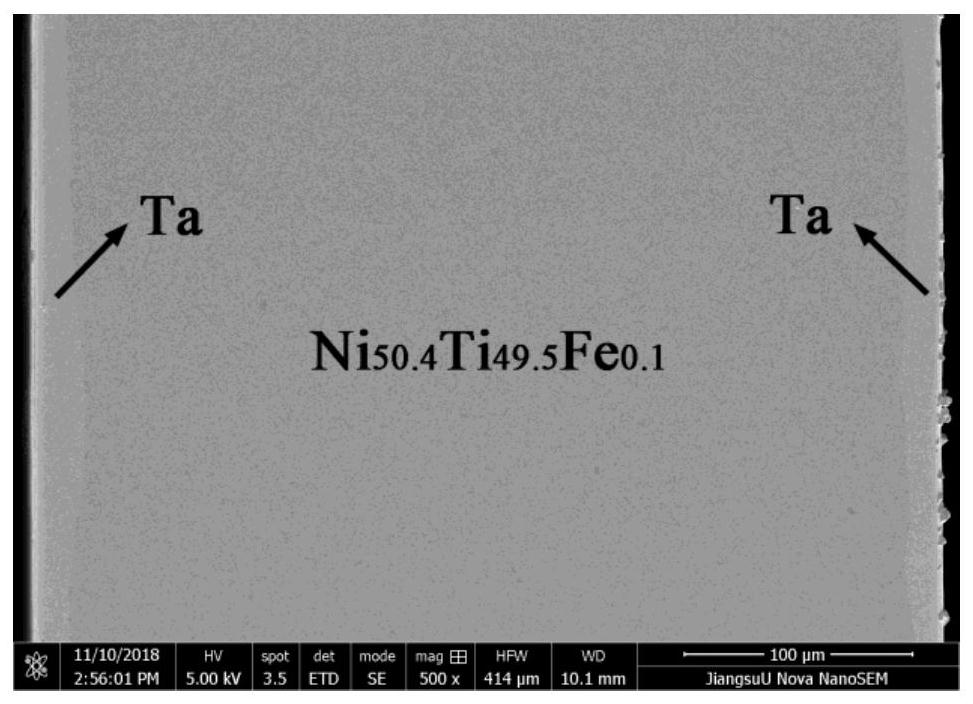

[0038] Inner layer material: choose Ni 50.4 Ti 49.5 Fe 0.1 alloy.

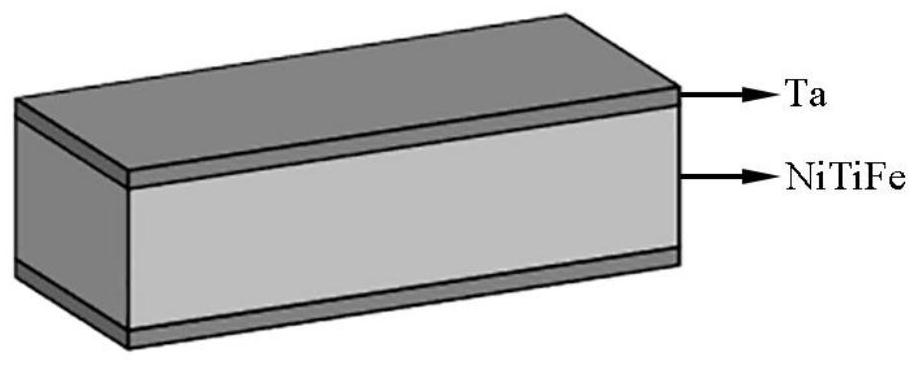

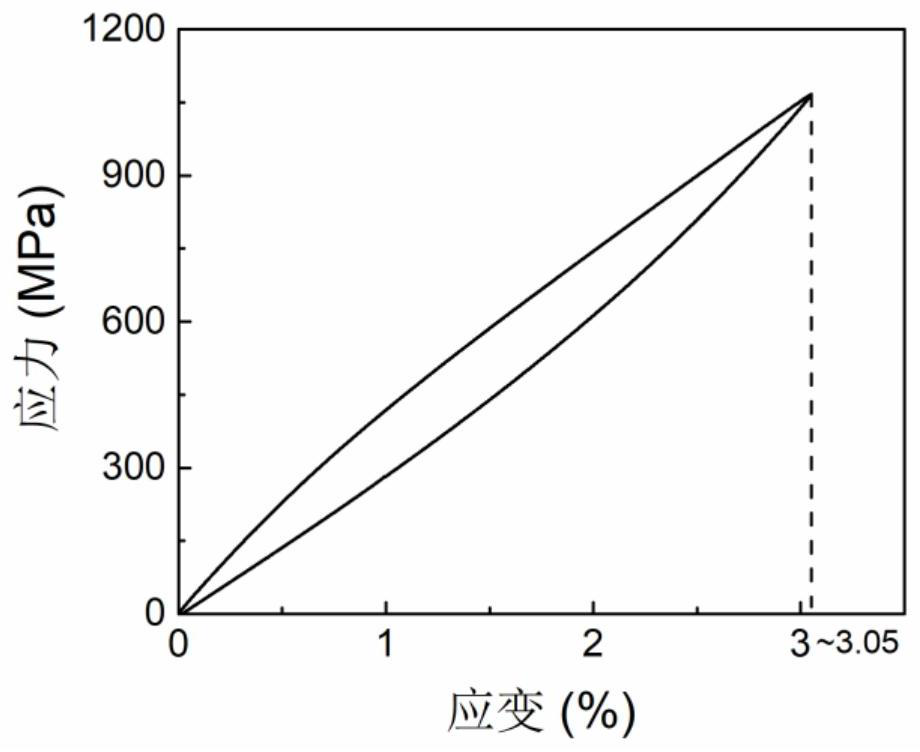

[0039] (2) Biomedical Ni 50.4 Ti 49.5 Fe 0.1 -Preparation of a large class of linear elastic composite materials, including:

[0040] ① Using wire cutting and / or machining methods, from high-purity Ta and Ni 50.4 Ti 49.5 Fe 0.1 Two high-purity Ta plates with a length of 70 mm, a width of 70 mm, and a thickness of 0.2 mm and a NiTiFe plate with a length of 70 mm, a width of 70 mm, and a thickness of 4.5 mm were cut from the blank;

[0041] ② Mechanically polish the cut high-purity Ta plate and NiTiFe plate on 200-mesh, 500-mesh, 1000-mesh and 1500-mesh sandpaper respectively, and then clean the surface with an ultrasonic cleaner;

[0042] ③Two high-purity Ta plates and a Ni plate...

Embodiment 2

[0054]The preparation operation of the present embodiment comprises the following steps:

[0055] (1) Selection of raw materials, including:

[0056] Outer layer material: select high-purity Ta (Ta content is 99.97wt.%);

[0057] Inner layer material: choose Ni 50.0 Ti 49.7 Fe 0.3 alloy.

[0058] (2) Biomedical Ni 50.0 Ti 49.7 Fe 0.3 -Preparation of a large class of linear elastic composite materials, including:

[0059] ① Using wire cutting and / or machining methods, from high-purity Ta and Ni 50.0 Ti 49.7 Fe 0.3 Two high-purity Ta plates with a length of 75 mm, a width of 75 mm, and a thickness of 0.25 mm and a NiTiFe plate with a length of 75 mm, a width of 75 mm, and a thickness of 5 mm were cut from the blank;

[0060] ② Mechanically polish the cut high-purity Ta plate and NiTiFe plate on 200-mesh, 500-mesh, 1000-mesh and 1500-mesh sandpaper respectively, and then clean the surface with an ultrasonic cleaner;

[0061] ③Two high-purity Ta plates and a Ni plate a...

Embodiment 3

[0073] The preparation operation of the present embodiment comprises the following steps:

[0074] (1) Selection of raw materials, including:

[0075] Outer layer material: select high-purity Ta (Ta content is 99.98wt.%);

[0076] Inner layer material: choose Ni 49.5 Ti 50.0 Fe 0.5 alloy.

[0077] (2) Biomedical Ni 49.5 Ti 50.0 Fe 0.5 -Preparation of a large class of linear elastic composite materials, including:

[0078] ① Using wire cutting and / or machining methods, from high-purity Ta and Ni 49.5 Ti 50.0 Fe 0.5 Two high-purity Ta plates with a length of 80 mm, a width of 80 mm, and a thickness of 0.3 mm and a NiTiFe plate with a length of 80 mm, a width of 80 mm, and a thickness of 5.5 mm were cut from the blank;

[0079]② Mechanically polish the cut high-purity Ta plate and NiTiFe plate on 200-mesh, 500-mesh, 1000-mesh and 1500-mesh sandpaper respectively, and then clean the surface with an ultrasonic cleaner;

[0080] ③Two high-purity Ta plates and a Ni plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com