Beer discharging faucet structure of draught beer machine

A draft beer machine and faucet technology, which is applied in the field of the structure of the tap of the draft beer machine, can solve the problems of unstable liquor output from the tap and the difficulty of replacing the spool of the tap, and achieve convenient replacement, stable liquor and stoppage. The effect of wine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

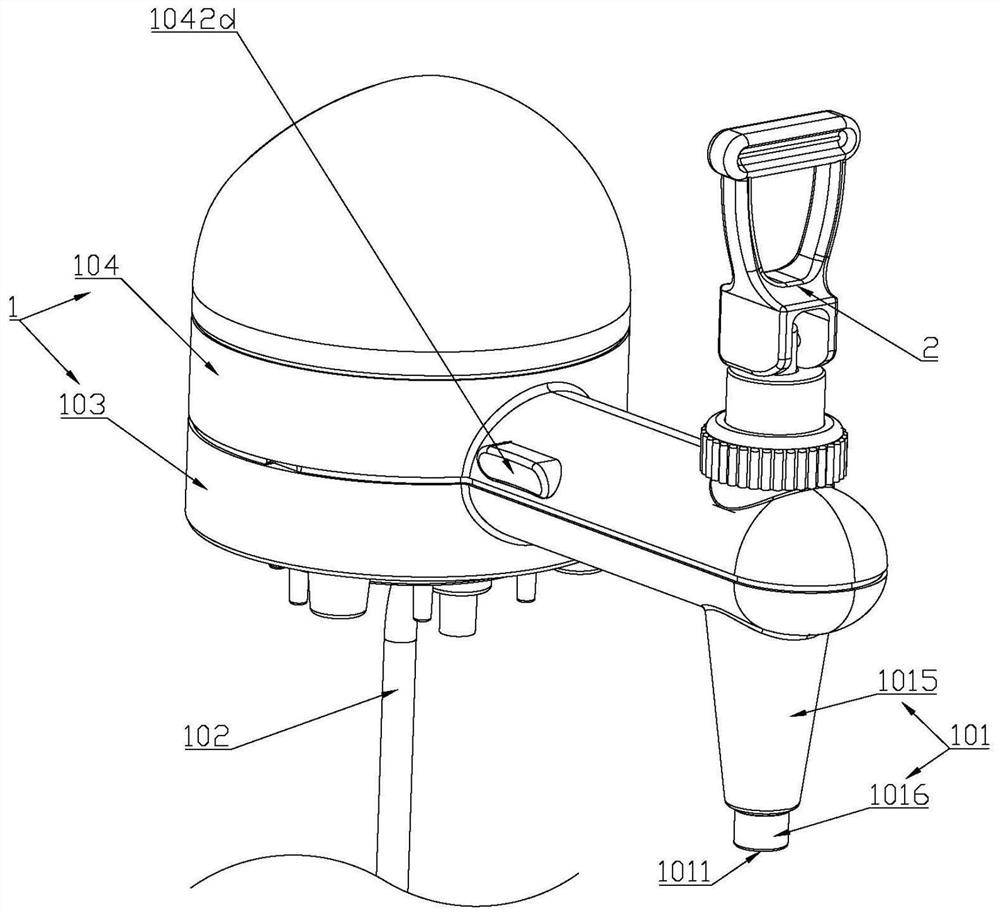

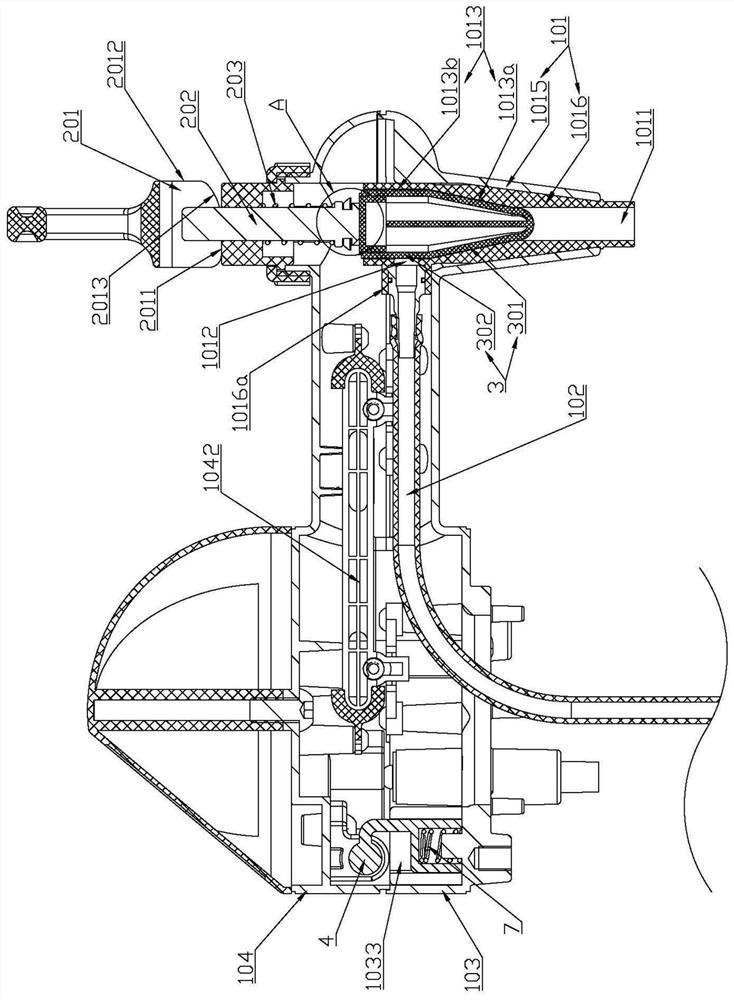

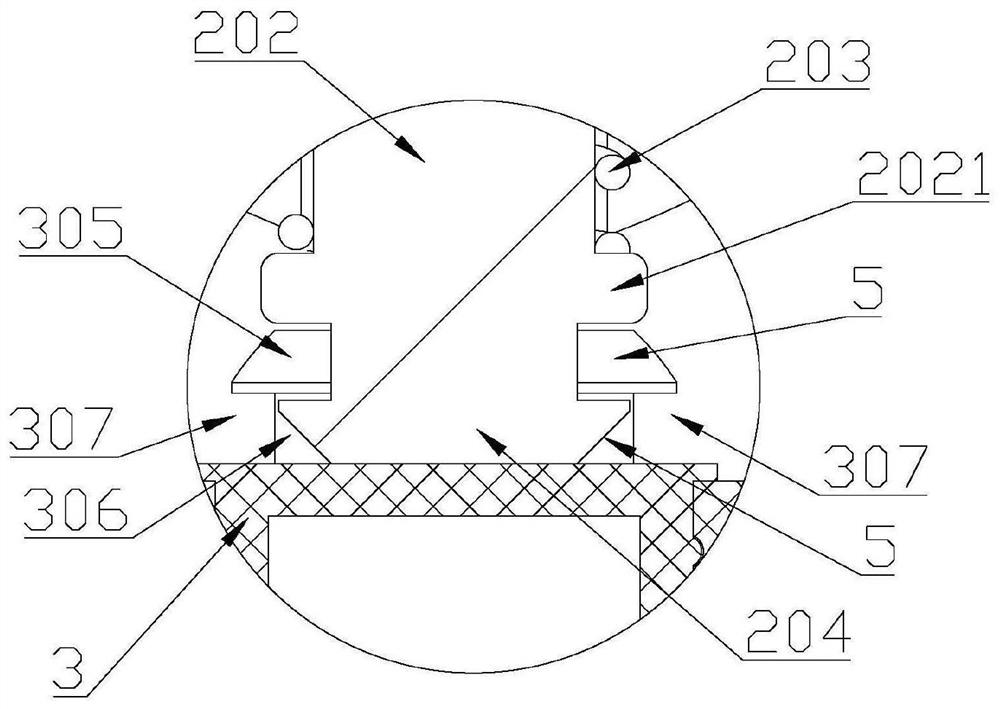

[0062] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0063] like figure 1 -9, a draft beer machine wine tap structure, including a wine head 1, an operating assembly 2, and a sealing valve core 3, the wine head 1 is provided with a wine end 101 and a fluid channel 102, the The wine outlet 101 has an outflow port 1011, an inflow port 1012, and a communication channel 1013 for connecting the outflow port 1011 and the inflow port 1012. One end of the fluid channel 102 is in fluid communication with the inflow port 1012, and the other end is in fluid communication with the inflow port 1012. The barrel establishes fluid communication;

[0064] The sealing spool 3 is matched with the communication channel 1013 and is movably ins...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap