Air quenching heat treatment process for high-chromium cast iron castings

A high-chromium cast iron and casting technology, used in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve problems such as quenching cracks in products with internal stress, shell strength that cannot withstand stress, and fast martensite transformation, and achieve stable quality. , Conducive to quality control, the effect of balanced hardness performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

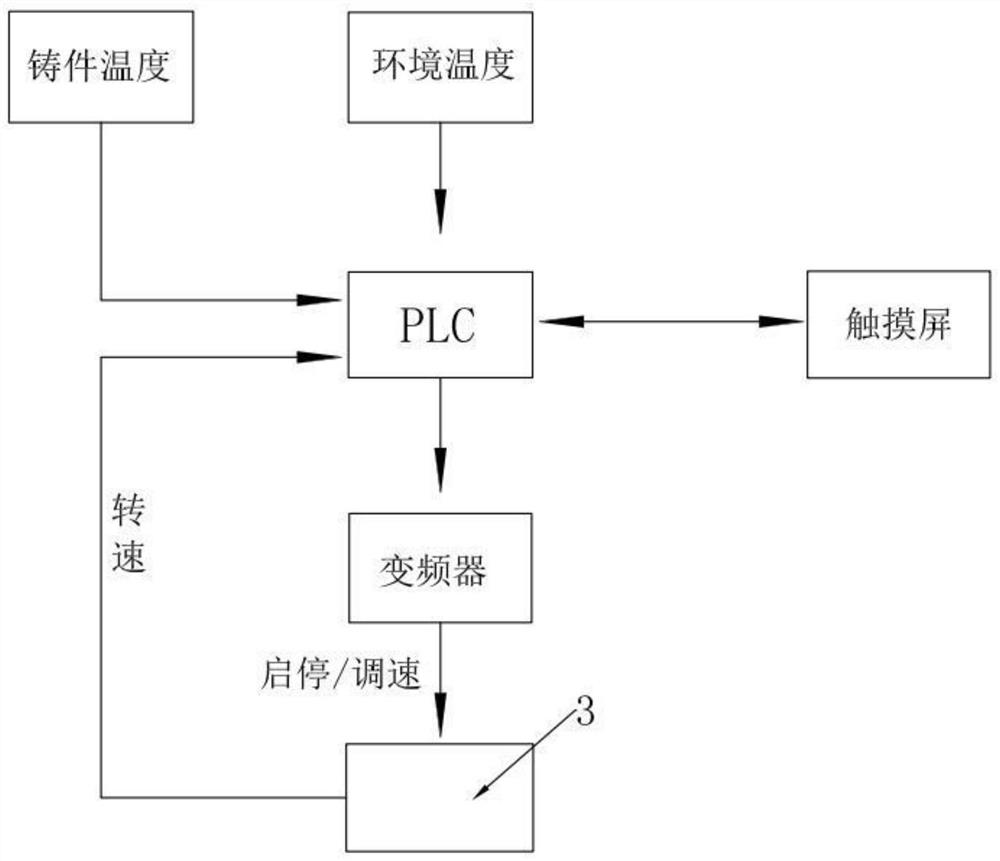

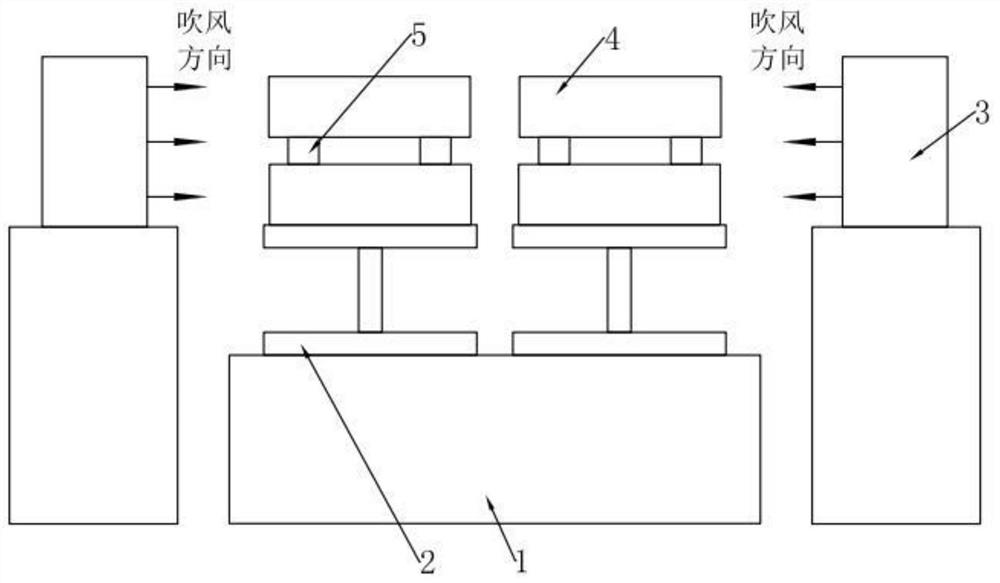

[0036] In this embodiment, the heat treatment device is used to heat treat the workpiece 2 42, including the furnace loading and stacking of the casting 4, heating up and cooling out of the furnace, and the specific steps are as follows:

[0037] Step 1: Place the workpiece 2 42 on the heat treatment furnace trolley 1 in the form of double rows and double layers, ensuring that the distance between the front and rear of the workpiece 2 42 is 350 mm, the distance between the left and right sides is 300 mm, and the distance between the upper and lower sides is 250 mm, and the middle is supported by hollow pad iron to ensure good ventilation Effect;

[0038] Step 2: Workpiece 2 42 enters the furnace to heat up, and check the sealing condition of the furnace door of the heat treatment furnace, and keep it at 1020°C for 7 hours. The specific heating process is as follows:

[0039] a: When the temperature of workpiece 242 is below 300°C, the heating rate is 150°C / h, and the holding t...

Embodiment 2

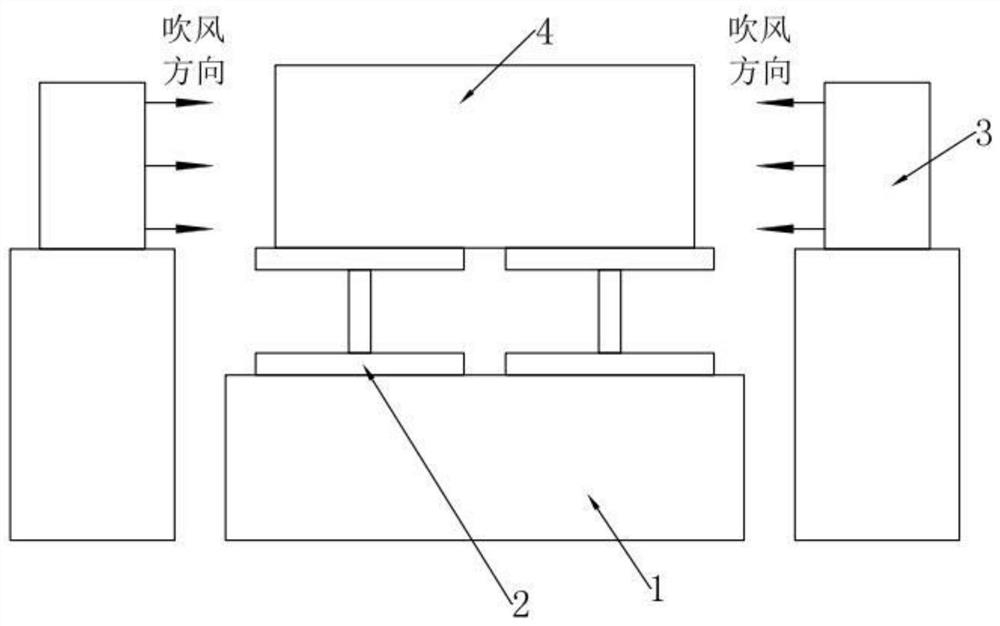

[0048] The heat treatment device of this embodiment performs heat treatment on the workpiece 41. The complete process includes the furnace loading and stacking of the casting 4, heating up and cooling out of the furnace. The specific steps are as follows:

[0049] Step 1: Place the workpiece 141 yards on the heat treatment furnace trolley 1. Since the casting 4 is large in size, it is stacked in a single row and single layer to ensure that the distance between the front and rear of the casting 4 is 400mm;

[0050] Step 2: Casting 4 enters the furnace to heat up, and check the sealing of the furnace door of the heat treatment furnace, and keep it at 1010°C for 9 hours. The specific heating process is as follows:

[0051] a: When the temperature of workpiece 141 is below 300°C, the heating rate is 130°C / h, and the holding time at 300°C is 2-3 hours;

[0052] b: When the temperature of the workpiece 141 is at the stage of 300-500°C, the heating rate is 60°C / h, and the holding tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com