Device and method for growing two-dimensional material based on manner of push-and-pull cart

A two-dimensional material and trolley technology, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve problems such as difficult to achieve growth effect, uncontrollable cooling range, sacrifice of raw material utilization rate, etc., to achieve surface Excellent quality, improved success rate, and the effect of increasing success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means and effects realized by the present invention easy to understand, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

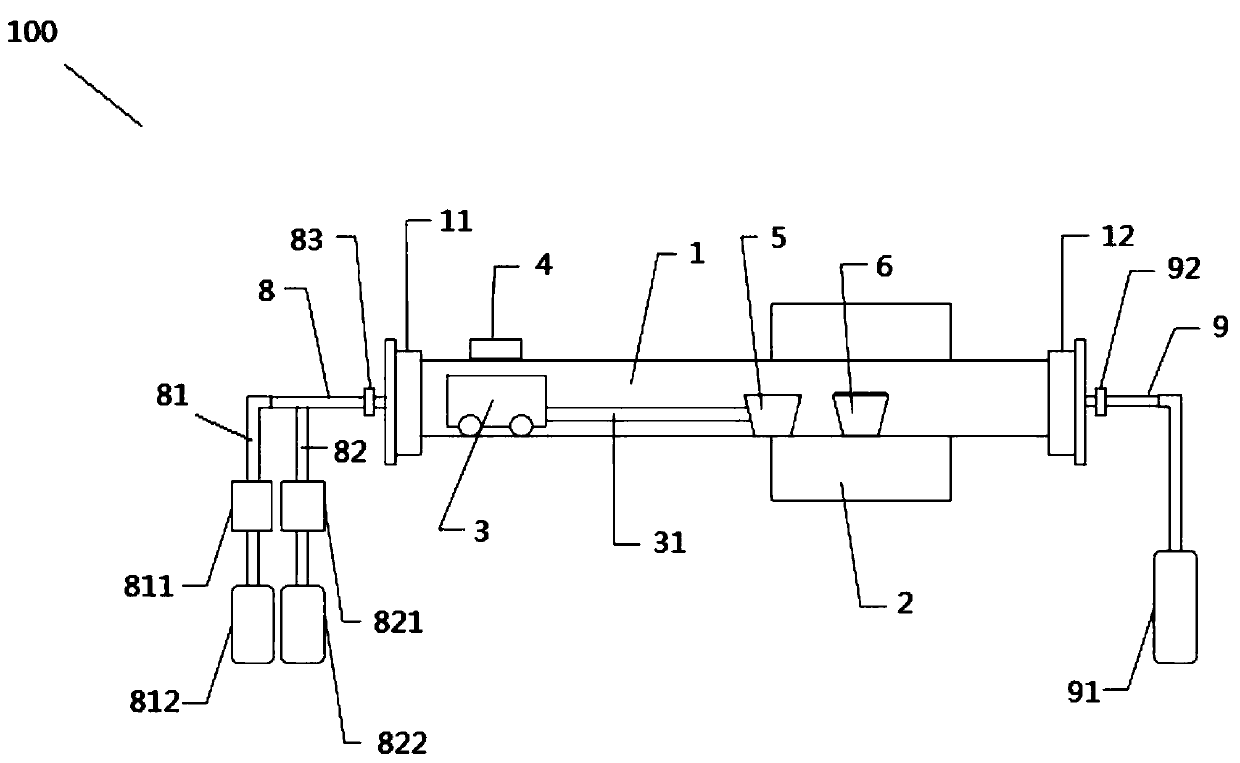

[0024] figure 1 It is a schematic structural diagram of a device for growing two-dimensional materials based on a push-pull trolley in an embodiment of the present invention.

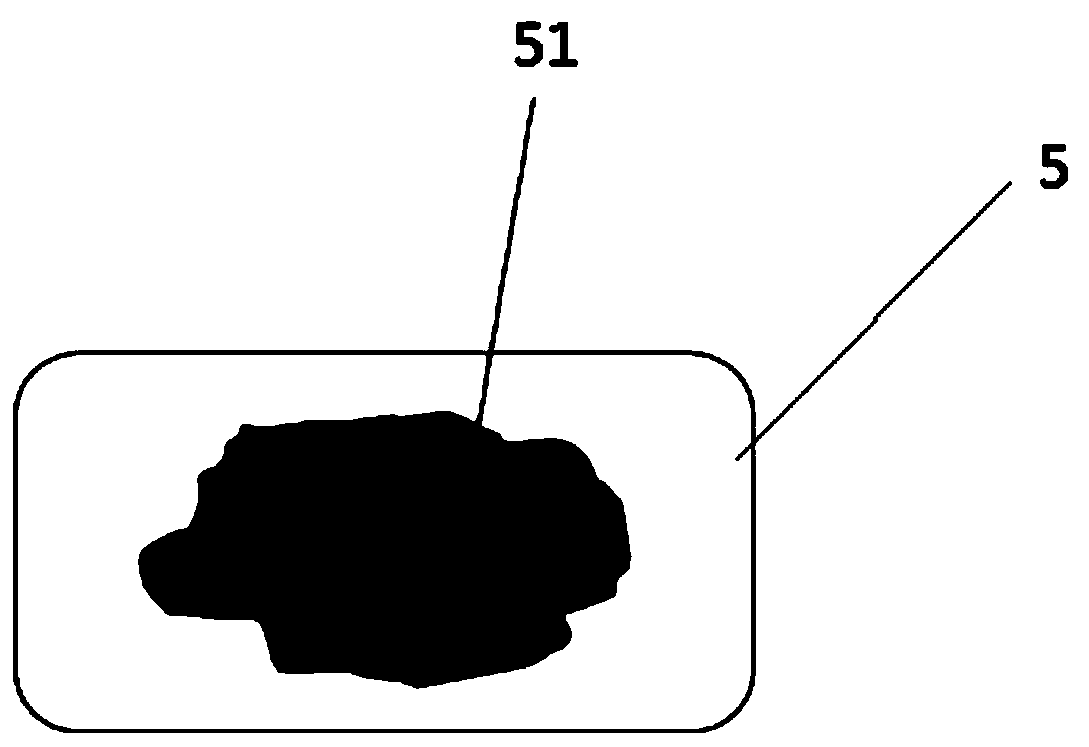

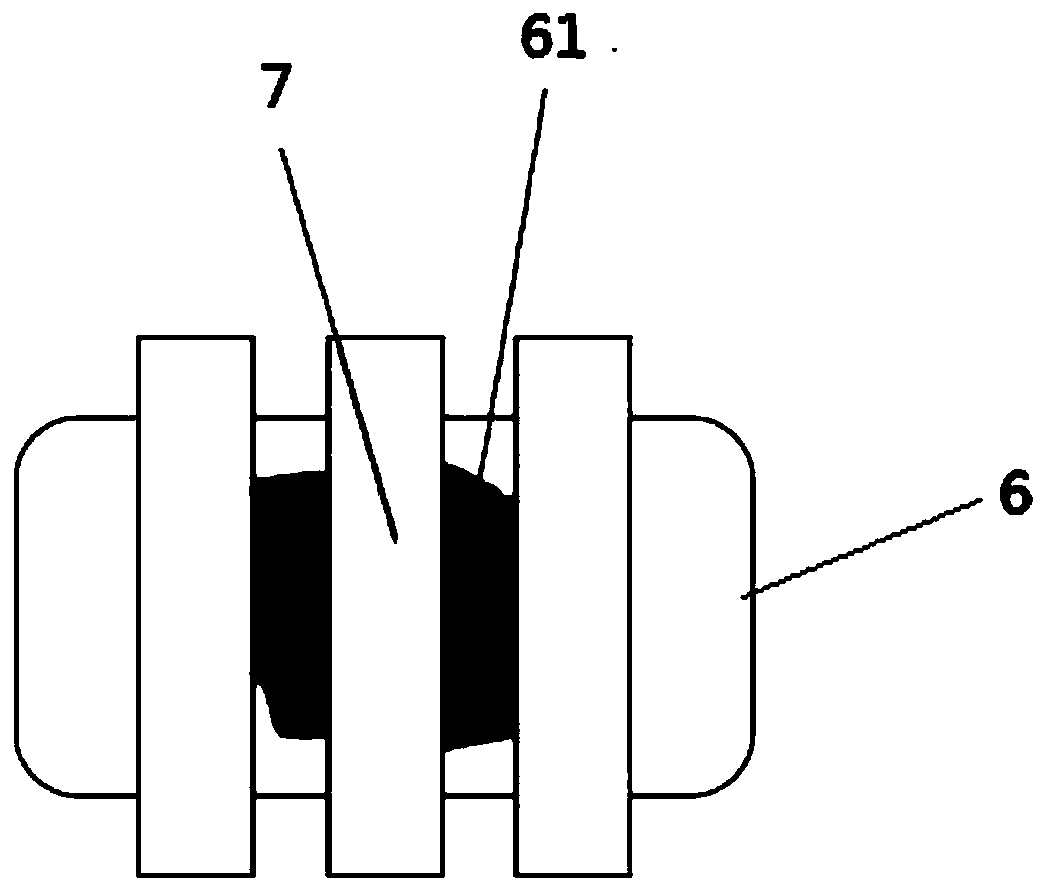

[0025] Such as figure 1 As shown, a device 100 for growing two-dimensional materials based on a push-pull trolley in this embodiment is used for the growth of two-dimensional materials, including: a reaction tube 1, a furnace 2, a trolley 3, a magnet 4, and a first quartz boat 5. The second quartz boat 6, the substrate 7, the gas inlet pipe 8 and the gas outlet pipe 9.

[0026]The reaction tube 1 has an inlet end provided with an inlet flange 11 and an outlet end provided with an outlet flange 12 .

[0027] The inlet flange 11 and the outlet flange 12 are used to seal the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com