Operating platform for replacing radial gate side water stop rubber and construction method of operating platform

A water-stop rubber and operating platform technology, which is applied in water conservancy projects, water conservancy engineering equipment, sea area projects, etc., can solve problems such as radians in gates, high maintenance costs, and potential safety hazards, so as to avoid shaking, save working time, and eliminate friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

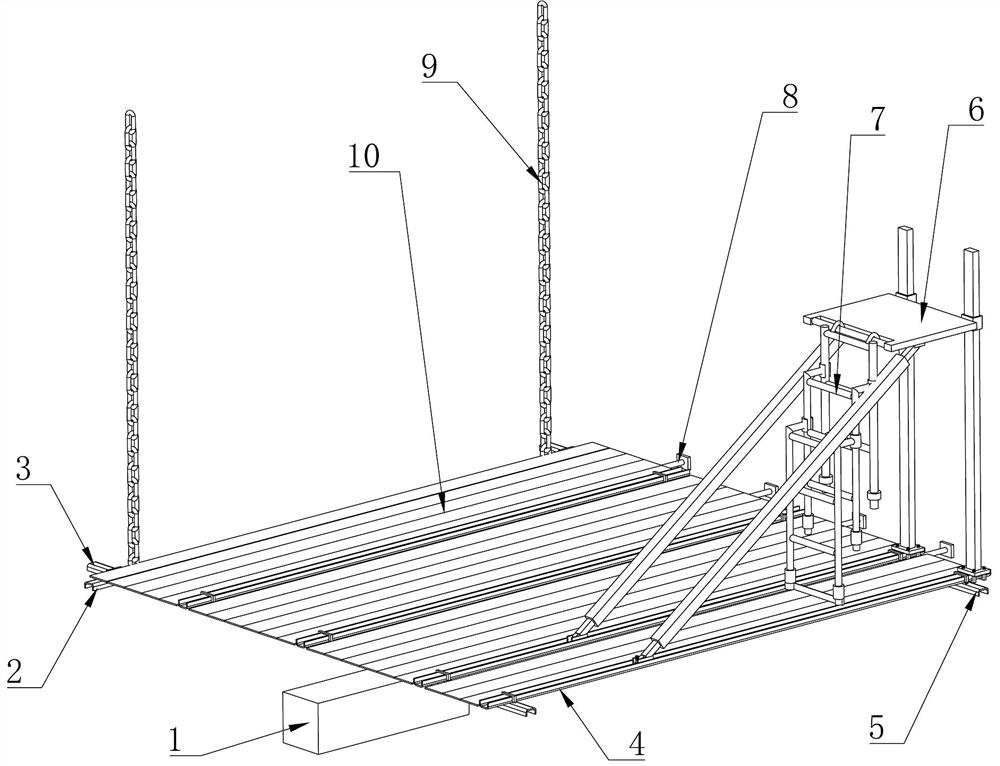

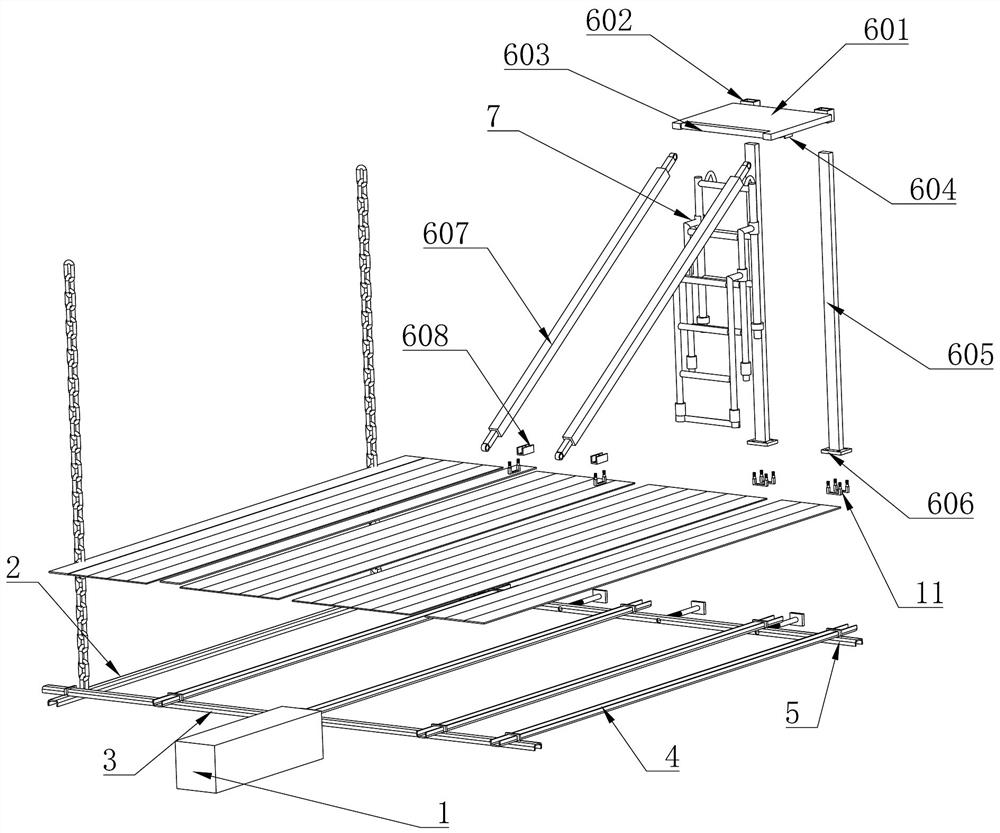

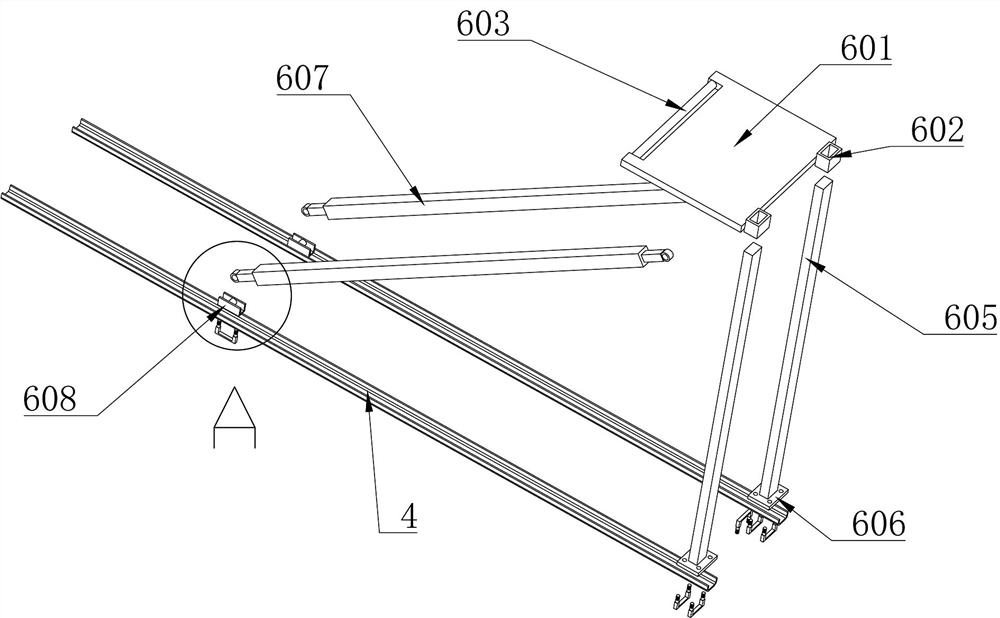

[0036] Such as Figure 1-7 Among them, an operation platform for replacing the water-stop rubber on the side of the arc gate, including an operation platform for replacing the water-stop rubber on the side of the arc gate, including a positioning channel steel 2, on which the positioning channel steel 2 is provided with a fixed channel steel 3, fixed The channel steel 3 is provided with a plurality of supporting channel steel 4, one end of the supporting channel steel 4 is connected with the fixed channel steel 3, the other end of the supporting channel steel 4 is provided with an adjusting channel steel 5, and the supporting channel steel 4 is provided with a lift that can slide up and down. Device 6, lifting device 6 is provided with the lift 7 that can expand and contract. With this structure, the square frame structure composed of different channel steels has stability, which can ensure the safety of the staff and prevent the workers from replacing the side water-stop rubb...

Embodiment 2

[0049] Further illustrate in conjunction with embodiment 1, as Figure 1~7 Shown, its method is: the maintenance gate is put into the gate hole that needs maintenance, and sling 9 is installed in the location channel steel 2 bolt holes. Put the channel steel, planks 10, U-shaped bolts 11, the disassembled lifting device 6 and the disassembled elevator 7 from the bridge surface to the two ends of the gate hole to the crossbeam 1 of the maintenance door, and operate it to the positioning slot with a car crane When the steel 2 is parallel to the crossbeam 1 of the maintenance door, the slings 9 at both ends are fixed. The car crane cooperates with the workers to set one end of the fixed channel steel 3 on the positioning channel steel 2, and the other end on the inspection door beam 1, one end of the horizontal adjustment channel steel 5 on the positioning channel steel 2, and multiple vertical support channel steels 4 set up on the fixed channel steel 3 and the adjustment chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com