High-precision linear optocoupler structure with adjustable transmission gain and coupling method thereof

A transmission gain, linear optocoupler technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of inability to meet the needs of analog signal transmission, large transmission gain deviation, insufficient transmission accuracy, etc., and achieve consistent optimized spectral response. performance and quantum efficiency, improved precision and nonlinearity, and the effect of optimizing process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

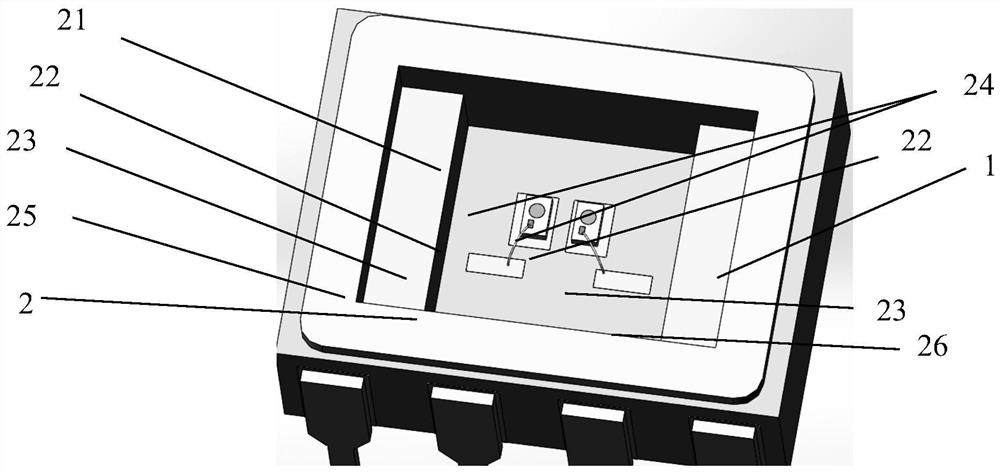

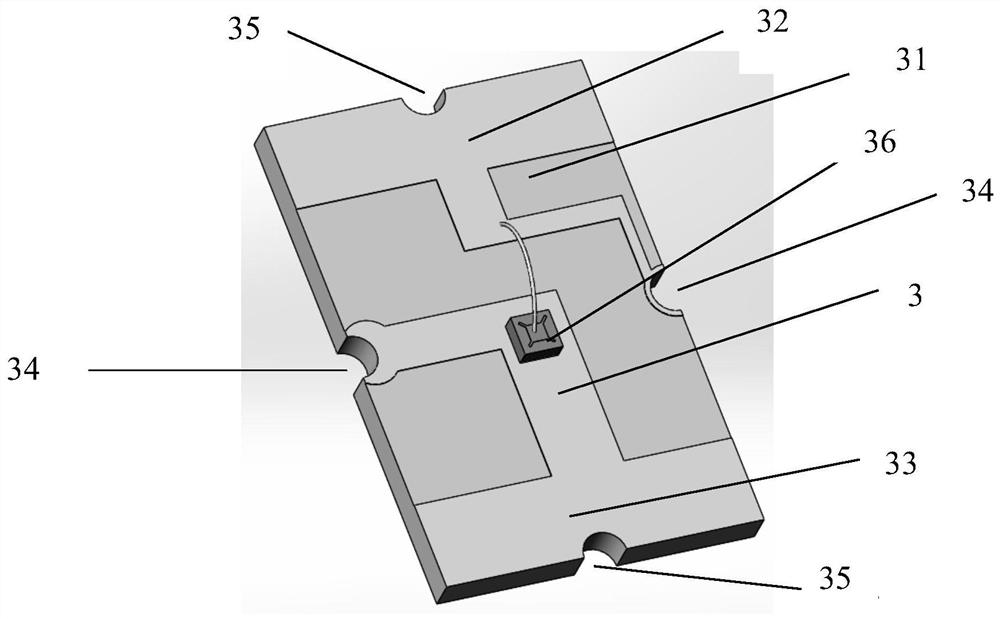

[0046] In this embodiment, a high-precision linear optocoupler structure with adjustable transmission gain, such as figure 1 , including a base 1, a photosensitive integrated board 2, a cover plate 3 and a packaging shell;

[0047] The inside of the base 1 is provided with a groove, which is used to place the photosensitive integrated board 2 and the cover plate 3;

[0048] Such as figure 1 , the photosensitive integrated board 2 includes: a base plate 21, two metal pads 22, two gold conduction strips 23, two photodetector chips 24, and two ceramic steps 24; the ceramic steps 25, 26 are respectively arranged on the base plate At the left and right ends of 21, the upper surface of the ceramic steps is gold-plated and connected to the corresponding metal outer pins of the package shell; the gold pad 22 and the gold conductive strip 23 are all arranged on the upper part of the upper plane of the bottom plate 21, and the two Two gold pads and two gold conduction strips are respe...

Embodiment 2

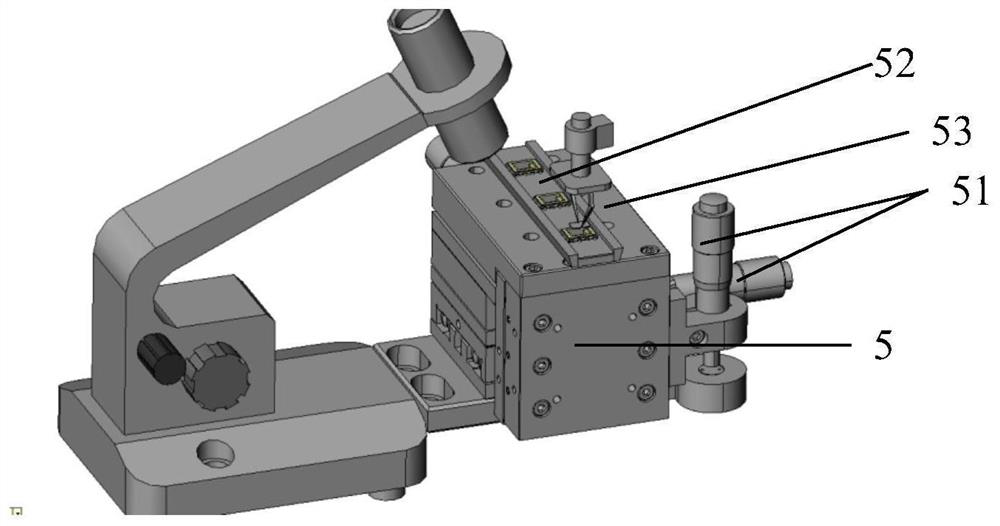

[0067] In this embodiment, a coupling method of a high-precision linear optocoupler structure with adjustable transmission gain is proposed, including:

[0068] Step 1: If image 3 , the micro-motion table 5 is set, and the micro-motion table can realize three axial displacements of X, Y, and Z through the adjustment knob 51;

[0069] Step 2: set special groove socket (52) on the micro-movement table 5, each groove socket is provided with a metal card slot, can clamp the package shell, the metal outer pin of package shell 4 passes through the metal card slot one one-to-one connection;

[0070] Step 3: Install the packaging shell (not yet hermetically sealed) including the base 1 and the photosensitive integrated board 2 in the recessed socket (52), the recessed socket (52) has built-in electrical leads, and the metal of the packaged shell can be realized. The electrical connection of the outer pins also realizes the electrical connection of each electrode of the photodetecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com