Automatic noodle cooking system and method

A noodle cooking and automatic technology, which is applied to cooking utensils with water bath devices, conveyor objects, timing control ignition mechanisms, etc., can solve the problem of inability to realize automation, inability to accurately place bowls and ingredients, and inability to place boxes and bowls one by one Access and other issues to achieve the effect of reducing manual labor and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

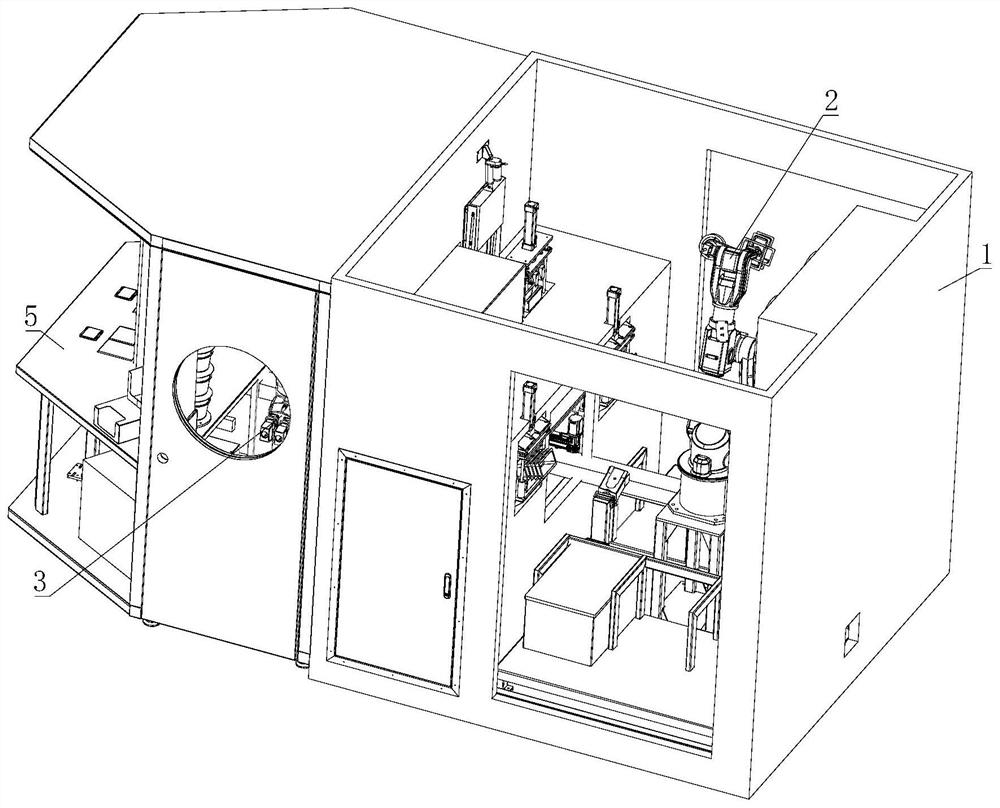

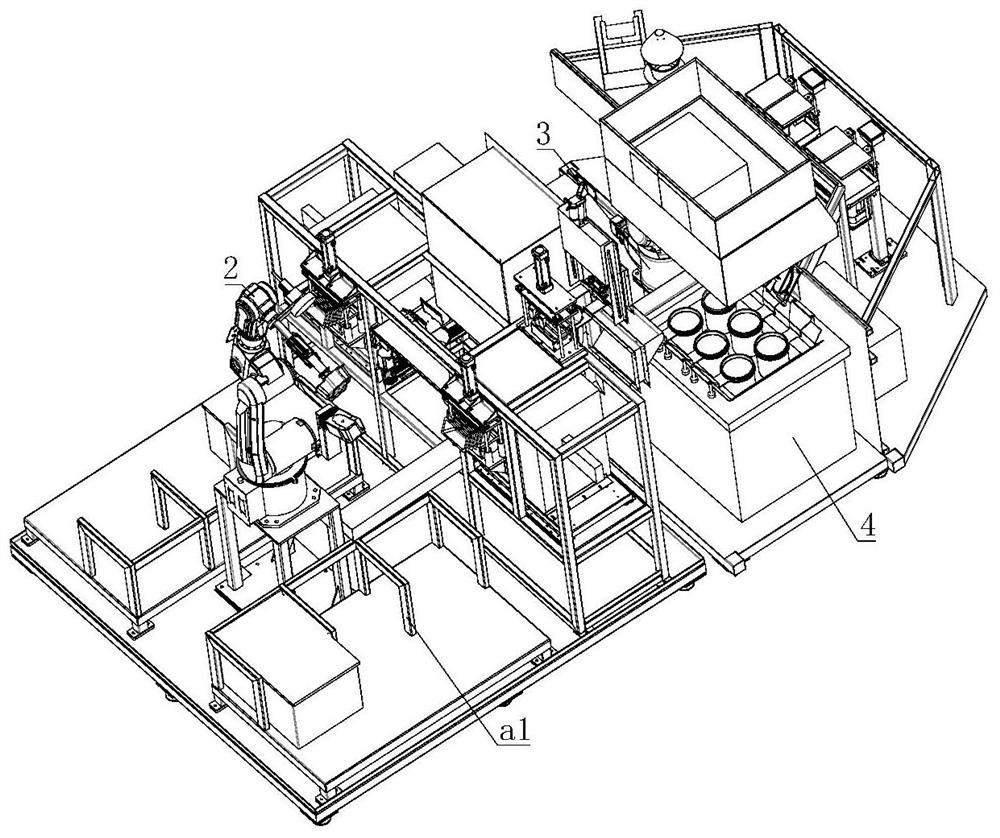

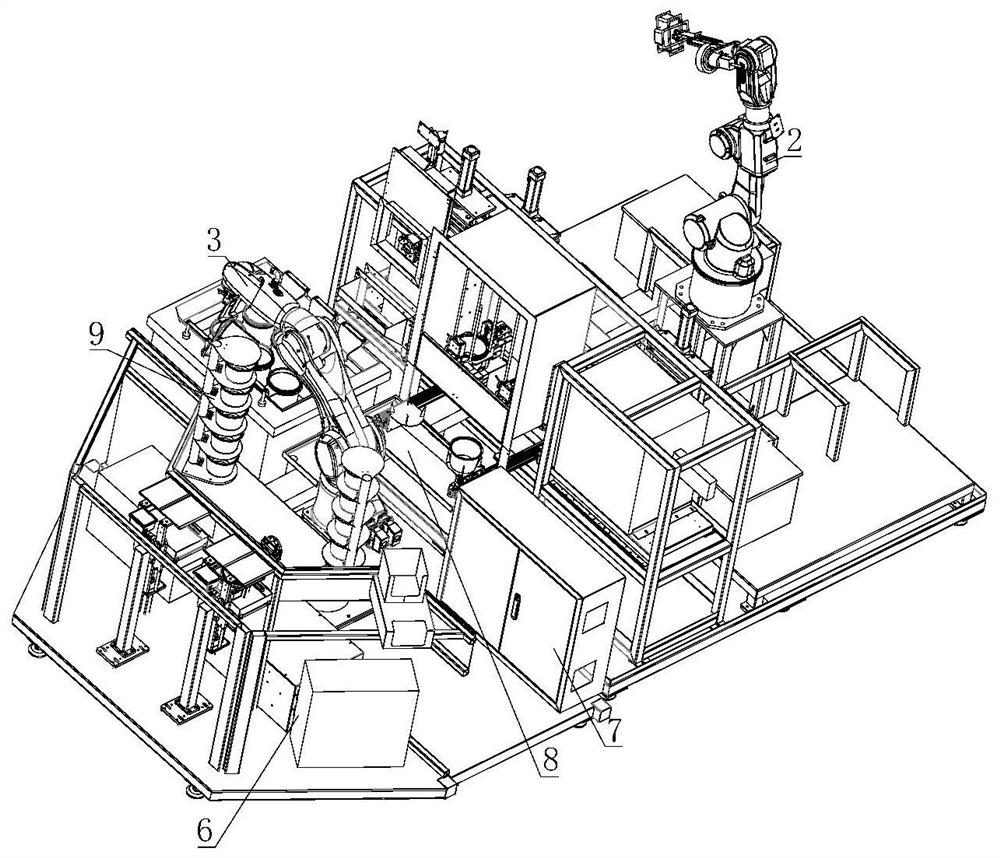

[0069] Such as Figure 1 ~ Figure 3 As shown, the automatic noodle cooking system of this embodiment includes a closed main body 1, a material shelf a1 and a background manipulator 2 are arranged in the closed main body 1, and a transfer mechanism a5 for absorbing material boxes in the material shelf a1 is connected to the background manipulator 2 , also includes a turning mechanism a6 for turning over the material box on the reverse side; a batching frame c1 is fixed inside the closed main body 1, and a breaching device for brea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap