Efficient industrial denitration device

A denitrification and industrial technology, applied in the field of high-efficiency industrial denitrification devices, can solve the problems of low denitrification efficiency, reduced work efficiency and performance, and inability to perform rapid denitrification, so as to improve denitrification efficiency, improve denitrification efficiency and performance, and effectively Conducive to the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

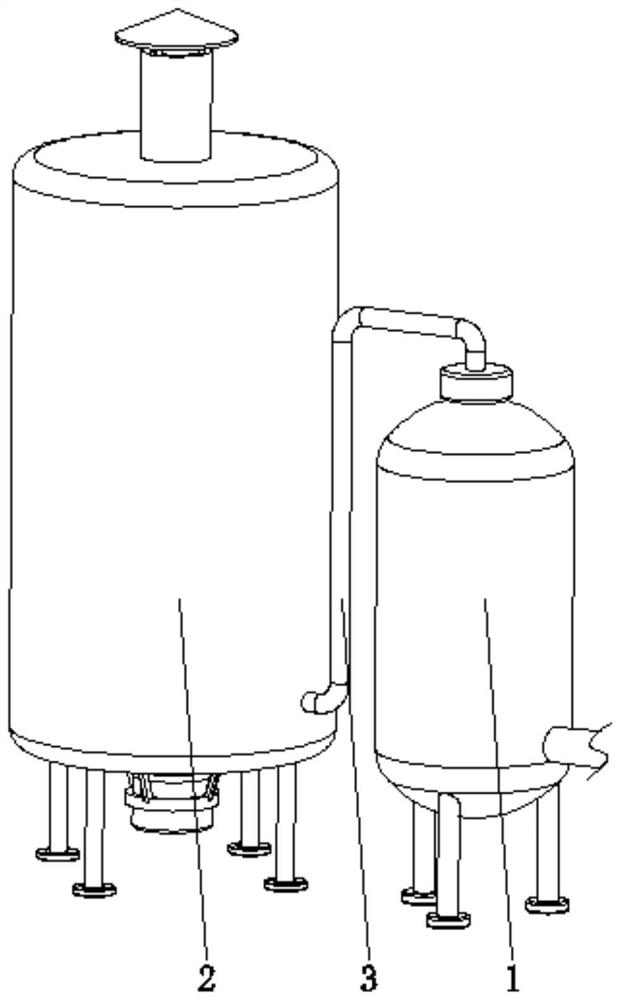

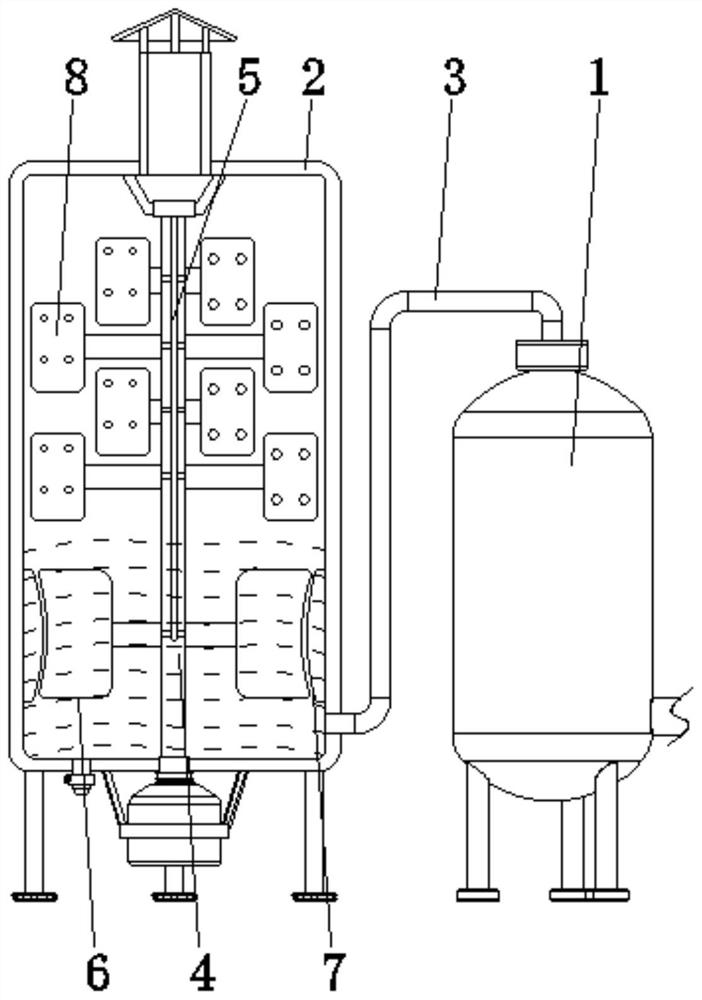

[0031] see Figure 1-7 , the present invention provides a technical solution: a high-efficiency industrial denitrification device, including a catalytic tank 1, a denitrification tank 2, and a connecting pipe 3, and the catalytic tank 1 and the denitration tank 2 are connected through the connecting pipe 3;

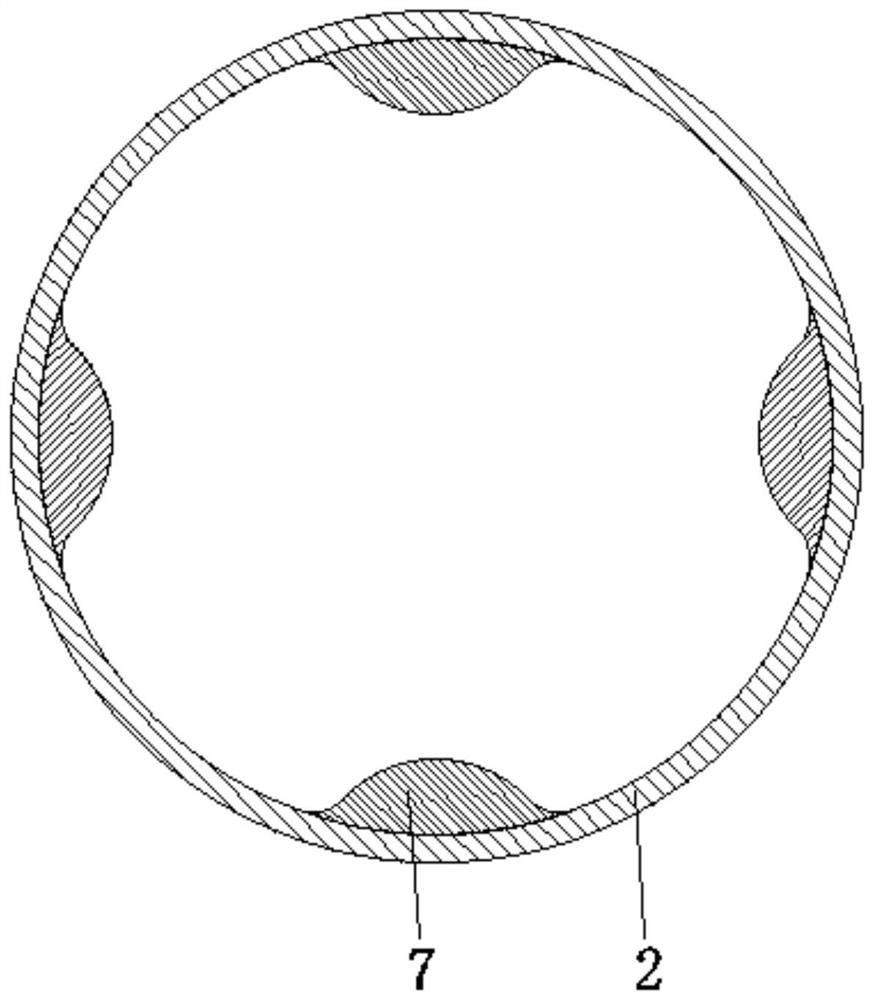

[0032] The interior of the denitrification tank 2 is provided with a driving shaft 4, a channel 5, a liquid mixing device 6, an arc surface bump 7, and a spraying device 8, and the driving shaft 5 is rotatably connected between the top and the bottom of the inner wall of the denitrification tank 2. , the channel 5 is opened at the central position inside the driving shaft 4, the liquid mixing device 6 is arranged at the bottom of the surface of the driving shaft 4, the arc-shaped protrusion 7 is fixed inside the denitrification tank 2 and corresponds to the position of the liquid mixing device 6, and the spraying device 8 is arranged on the top of the surface of the drivi...

Embodiment example 2

[0034] The liquid mixing device 6 is provided with a support rod 61, a liquid flow channel 62, and a stirring device 63. One end of the support rod 61 is fixedly connected to the surface of the drive shaft 4, and the liquid flow channel 62 is set at the inner center of the support rod 61 and connected to the channel 5. connected, the stirring device 63 is arranged on the end of the support rod 61 away from the driving shaft 4, when the gas in the connecting pipe 3 enters the denitrification tank 2, the gas reacts with the alkaline solution in the denitrification tank 2, and is driven by the driving shaft 4 Next, at this time, the support rod 61 and the stirring device 63 rotate at the same time, and then the alkaline solution is stirred, so that the gas is fully reacted, which is conducive to rapid denitrification and improves the denitrification efficiency.

[0035] The stirring device 63 is provided with an arc plate 631, a U-shaped sleeve 632, an elastic capsule body 633, an...

Embodiment example 3

[0037]The spraying device 8 is provided with a connecting rod 81, a spray flow channel 82, and a fan plate device 83. One end of the connecting rod 81 is fixedly connected with the surface top of the drive shaft 4, and the spray flow channel 82 is set at the inner central position of the connecting rod 81 and is connected to the channel. 5 connected, the fan device 83 is fixed on the end of the connecting rod 81 away from the driving shaft 4, when the driving shaft 4 rotates, it will drive the connecting rod 81 and the fan device 83 to rotate at the same time, and the inclined fan device 83 is rotating Under certain circumstances, the sprayed alkaline mist is fully stirred and mixed with the remaining toxic and harmful gases to reduce the emission of residual toxic and harmful gases, which is conducive to further denitrification.

[0038] The fan plate device 83 is provided with a plate body 831, an airflow hole 832, and a spray head 833. The plate body 831 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com