Light composite protection structure

A composite protective structure and protective structure technology, which is applied in the direction of protective clothing, protective equipment, synthetic resin layered products, etc., can solve the problems of reducing the protective efficiency of fiber fabrics and weakening the protective performance of fiber fabrics, so as to improve the protective effect and minimize the The effect of increasing the damage and roughness of the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Nano-SiO with a particle size of 80nm 2 Add the powder into PEG-200 (polyethylene glycol with a molar mass of 200g / mol), and after ultrasonically dispersing evenly, add B with a particle size of 1 μm to 10 μm 4 C powder, continue to ultrasonically disperse, transfer to a vacuum drying oven to dry for 24 hours to remove air bubbles after uniform dispersion, and obtain B 4 C modified shear thickening protective fluid;

[0028] Among them, nano-SiO 2 The mass fraction of powder is 20%, B 4 The mass fraction of C powder is 10%, and the mass fraction of PEG-200 is 70%;

[0029] (2) Absolute ethanol and B 4 C modified shear thickening protection liquid is mixed according to the mass ratio of 10:7, and mixed evenly to obtain diluted B 4 C modified shear thickening protective fluid;

[0030] (3) Immerse the single-layer fiber fabric (Twaron CT709) in diluted B 4 C modified shear thickening protection solution, then take it out and place it in a constant temperature e...

Embodiment 2

[0033] Steps (1)~(3) are identical with embodiment 1 steps (1)~(3);

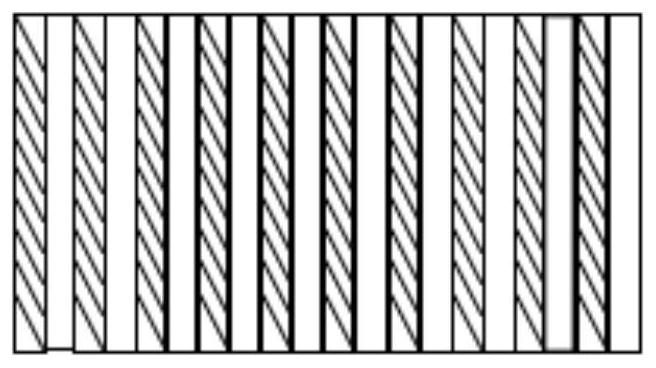

[0034] (4) The modified single-layer fiber fabric and the unmodified single-layer fiber fabric (Twaron CT709) are superimposed together as a composite fabric layer, and the surface density of the composite fabric layer is 444.4g / m 2 ; 8 layers of composite fabric layers with a total mass of 320g and 24 layers of PE laminates with a total mass of 480g (area density of 222.2g / m 2 ) are alternately arranged (one layer of composite fabric layer and three layers of PE laminate as a repeating cycle), wherein, the facing surface is a modified single-layer fiber fabric in the composite fabric layer, and the back surface is PE laminate, and the surface density 8.89kg / m 2 Lightweight composite protective structures, such as image 3 shown.

Embodiment 3

[0036] Steps (1)~(3) are identical with embodiment 1 steps (1)~(3);

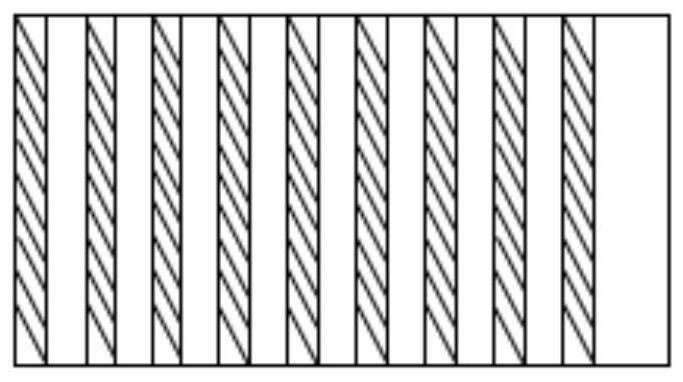

[0037] (4) The modified single-layer fiber fabric and the unmodified single-layer fiber fabric (Twaron CT709) are superimposed together as a composite fabric layer, and the surface density of the composite fabric layer is 444.4g / m 2 ; 7 layers of composite fabric layers with a total mass of 280g and 26 layers of PE laminates with a total mass of 520g (area density of 222.2g / m 2 ) are alternately arranged (one layer of composite fabric layer and three layers of PE laminates as a repeating cycle, and the remaining five layers of PE laminates are stacked with the three layers of PE laminates in the last cycle as a backboard), among which, the The surface is a modified single-layer fiber fabric in the composite fabric layer, and the back surface is a PE laminate, and the surface density is 8.89kg / m 2 Lightweight composite protective structures, such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com