Vacuum packaging equipment and using method thereof

A technology of vacuum packaging and equipment, which is applied in the directions of packaging, transportation packaging, transportation and packaging, etc., which can solve the problems that the automatic process of labeling material bag labeling cannot be realized, and achieves a small footprint and good layout. Compact, highly automated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

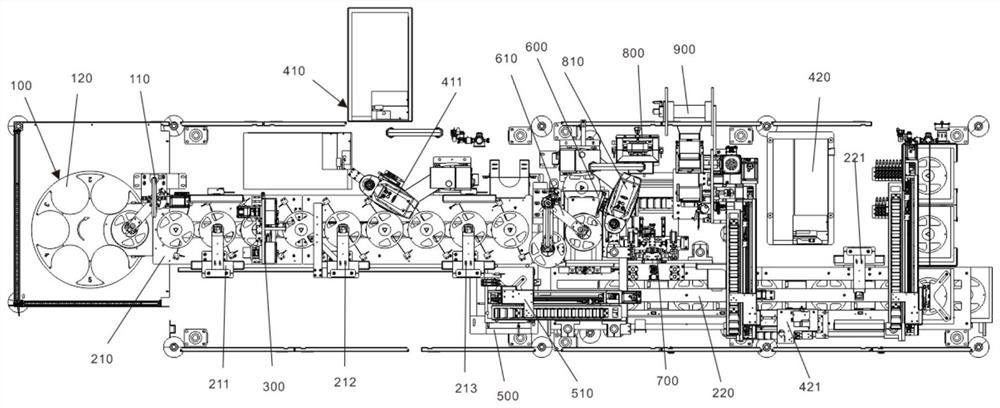

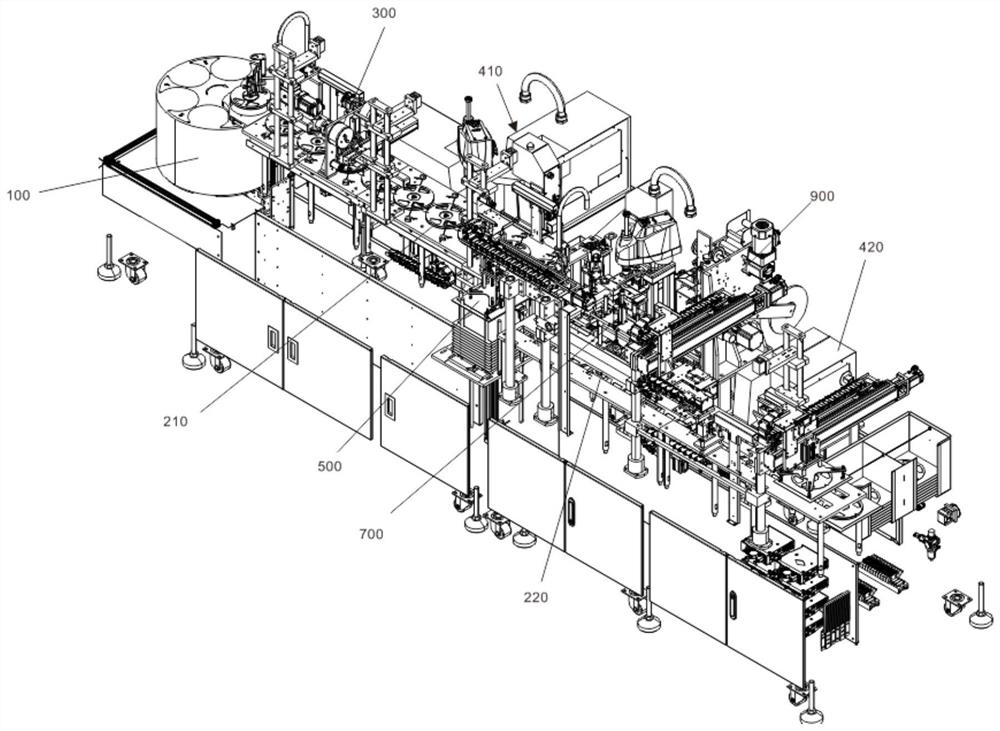

[0068] refer to figure 1 , figure 2 , a kind of vacuum packaging equipment includes a material feeding device 100, a first transportation device 210, a label tearing device 300, a first labeling device 410, a material bag feeding device 500, a charging device 600, a second transportation device 220, Vacuum bag sealing device 700, the second labeling device 420 and several manipulators;

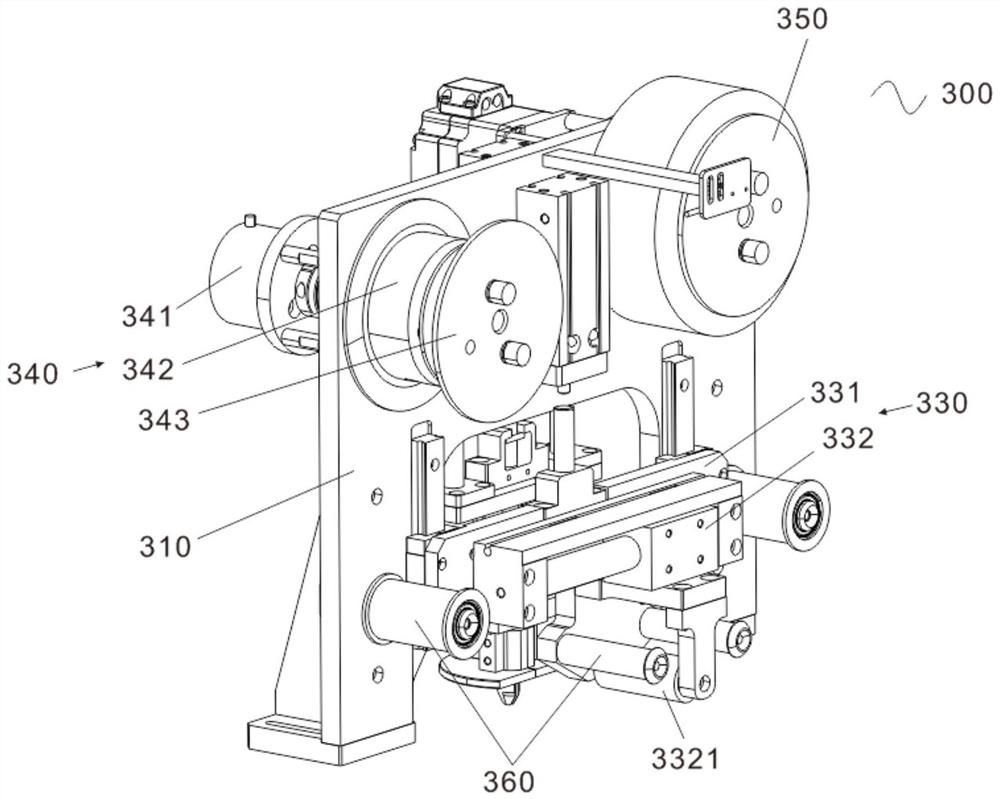

[0069] The label tearing device 300 is located on the first transportation device 210, and the first transportation device 210 has a rotating jacking mechanism to rotate the material to facilitate the label tearing device 300 to accurately tear off the label; the station is located at the After the label tearing device 300 and next to the first transport device 210, the first labeling device 410 is provided, and the charging device 600 is located at the end of the first transport device 210 for transporting the material to the material. inside the bag;

[0070] The material bag feeding dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com