Roasting treatment method for high-lead, high-copper and high-iron zinc concentrate

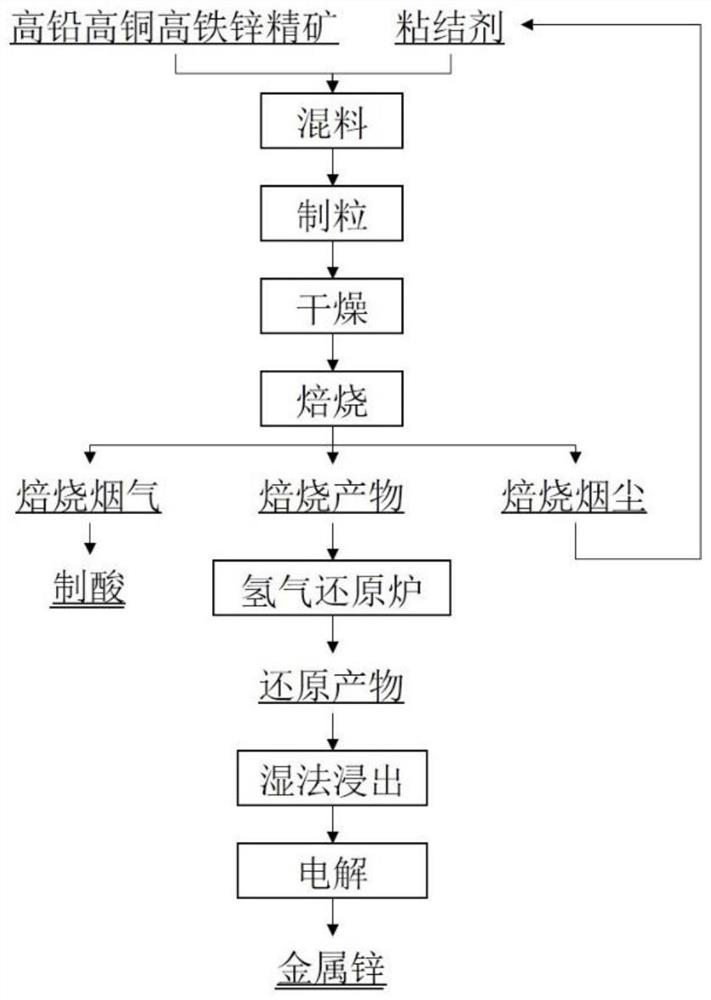

A processing method and technology of zinc concentrate, applied in the field of metallurgy, can solve the problems of low soluble zinc content, roasting and bonding, etc., and achieve the effects of improving bed capacity, reducing the amount of smoke and dust, and solving the problems of roasting and bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

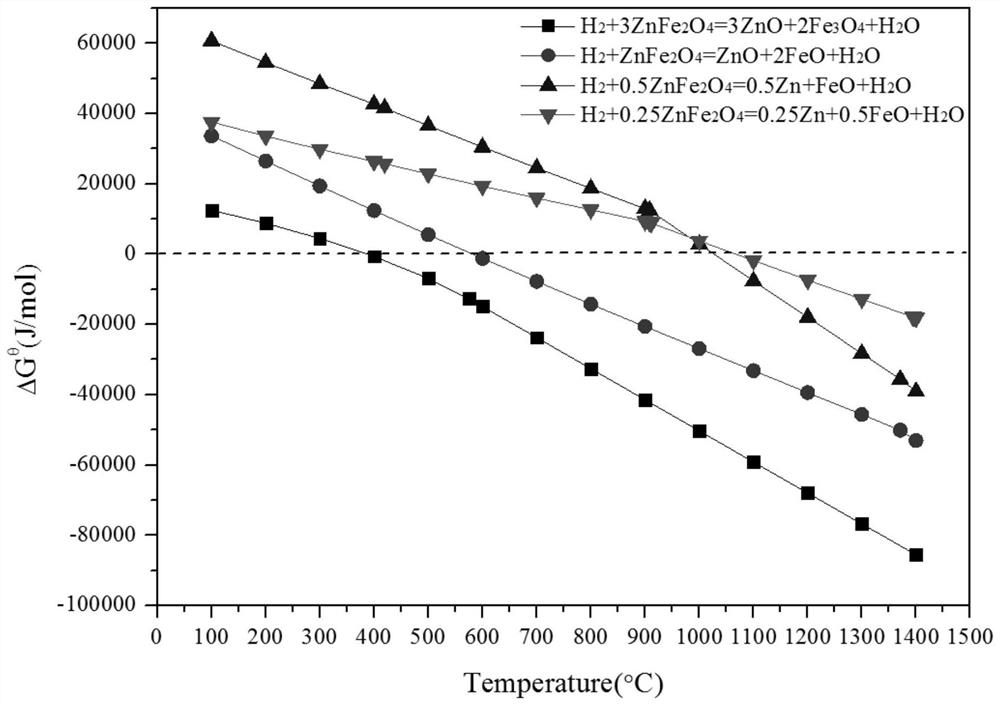

Method used

Image

Examples

Embodiment 1

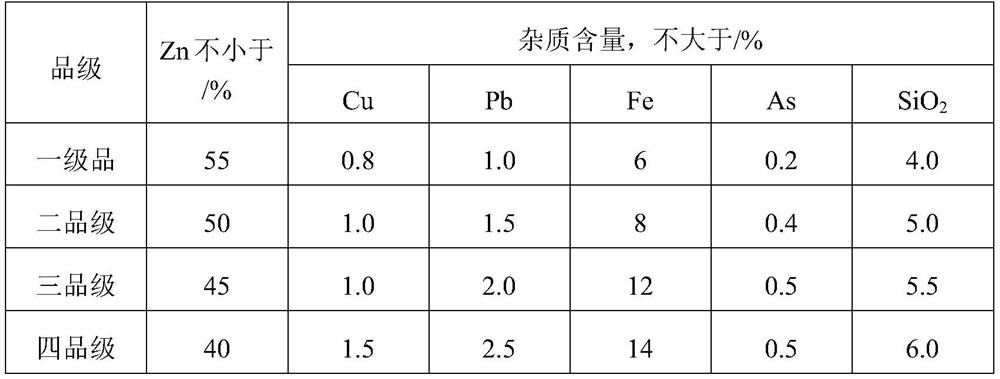

[0043] The content of main elements in a high-lead, high-copper, high-iron-zinc concentrate is shown in the table below, which contains 8.6% lead, 3.2% copper and 7.8% iron. The zinc concentrate is mixed with return dust (smoke dust returned in the oxidation roasting process) and dilute sulfuric acid (40wt%) according to a mass ratio of 90:8:2, and after mixing evenly, it is granulated by a disc granulator to ensure The prepared particles meet the requirements of 0.5-5mm, and the proportion of 1-2mm particles is more than 75%. Dry the granulated material to ensure that the water content in the material is less than 1%.

[0044] at 10m 2 Take the fluidized roasting furnace as an example, the capacity of the fluidized furnace bed can reach 24t / m 2 ·d, the feeding amount per hour is 10t, the roasting treatment is carried out at 960°C, the roasting time is 4h, the air injection linear velocity is 2.3m / s, and the smoke and dust output during the roasting process is 11.5%. The ca...

Embodiment 2

[0048] The content of main elements in a high-lead, high-copper, high-iron-zinc concentrate is shown in the table below, which contains 3.5% lead, 2.1% copper and 14.2% iron. Mix the zinc concentrate with zinc sulfate and water according to the mass ratio of 92:6:2, and use a cylinder granulator to granulate after mixing evenly to ensure that the obtained particles meet the requirements of 0.5-5mm, and the proportion of 2-3mm particles is Up to 75% or more. Dry the granulated material to ensure that the water content in the material is less than 1%.

[0049] at 10m 2 Take the fluidized roasting furnace as an example, the capacity of the fluidized furnace bed can reach 26t / m 2 ·d, the feeding amount per hour is 10.83t, the roasting treatment is carried out at 1050°C, the roasting time is 5h, the air injection linear velocity is 2.5m / s, and the smoke and dust output during the roasting process is 10.9%. The calcined sand produced by the fluidized fluidized furnace flows into ...

Embodiment 3

[0053] The content of main elements in a high-lead, high-copper, high-iron-zinc concentrate is shown in the table below, which contains 4.5% lead, 2.5% copper and 6.5% iron. The zinc concentrate is mixed with return dust (smoke dust returned in the oxidation roasting process) and dilute sulfuric acid (10wt%) according to a mass ratio of 90:8:2, and after mixing evenly, it is granulated by a disc granulator to ensure The prepared particles meet the requirements of 0.5-5mm, and the proportion of 3-4mm particles is more than 75%. Dry the granulated material to ensure that the water content in the material is less than 1%.

[0054] at 10m 2 Take the fluidized roasting furnace as an example, the capacity of the fluidized furnace bed can reach 30t / m 2 ·d, the feeding amount per hour is 12.5t, the roasting treatment is carried out at 1000°C, the roasting time is 3h, the air injection linear velocity is 2.6m / s, and the amount of smoke produced during the roasting process is 9.8%. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com