A kind of high-strength and toughness Ti-rich nanoparticle reinforced cual-based composite material and its preparation method and application

A composite material and nanoparticle technology, applied in the field of new powder metallurgy materials, can solve the problems of low material uniform deformation ability, easy growth, delivery, and reduction of material stacking fault energy, etc., to achieve flexible and adjustable structure and composition, and low price , the effect of a wide range of equipment options

Active Publication Date: 2022-05-31

JINAN UNIVERSITY

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Research on CuAl alloys in recent years has shown that because Al can significantly reduce the stacking fault energy of the material, a large number of deformation twins can be formed during the deformation process of the material, thereby improving the strength of the material, but due to the instability of the twin structure, in During the tensile deformation process, the material is prone to growth, delivery and other behaviors, and the material softens after a short period of work hardening, which makes the material's uniform deformation ability low and prone to necking fracture

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

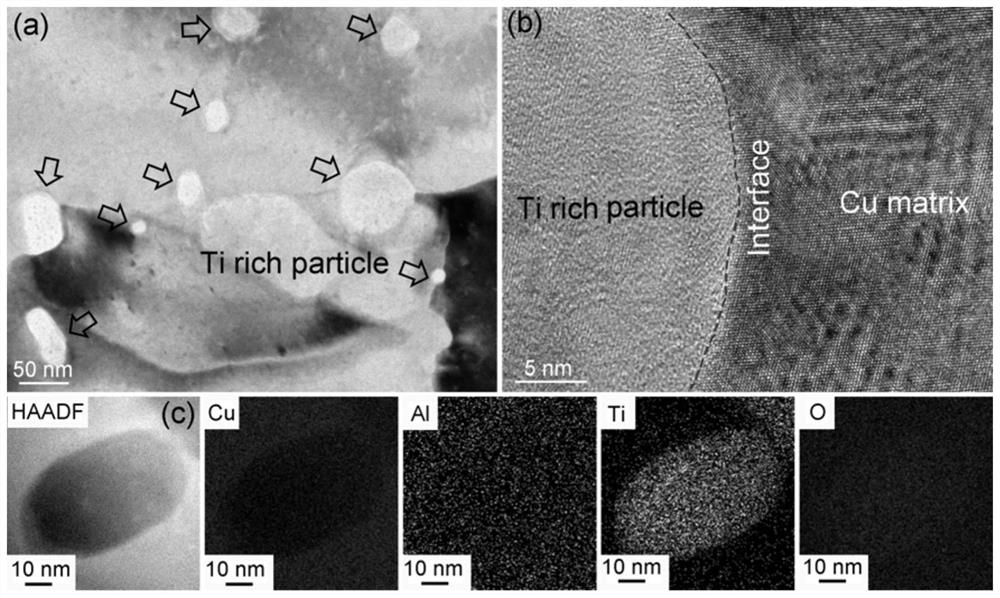

[0033] Preparation of Ti-rich nano-particle enhanced CuAl matrix composite material, the raw material used is 4.05wt.% Al powder, 2.55wt.%

Embodiment 2

[0035] Preparation of Ti-rich nano-particles reinforced CuAl matrix composite material, the raw material used is 3.03wt.% Al powder, 2.12wt.%

Embodiment 3

[0037] Preparation of Ti-rich nano-particle reinforced CuAl-based composite material, the raw material used is 2.1wt.% Al powder, 1.47wt.% nano

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

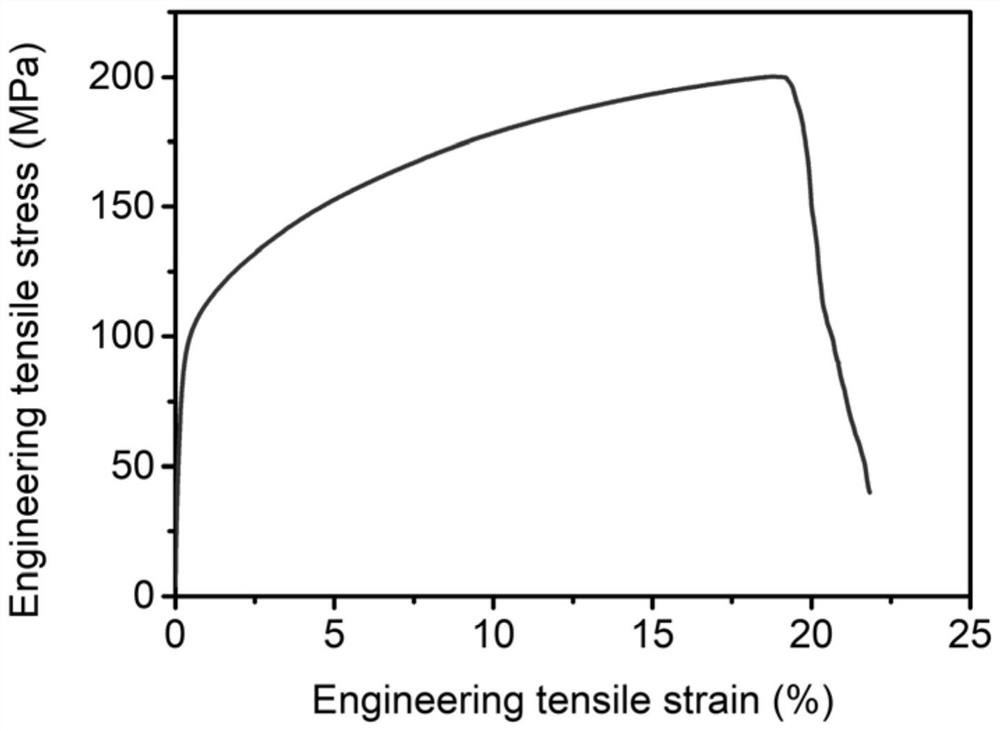

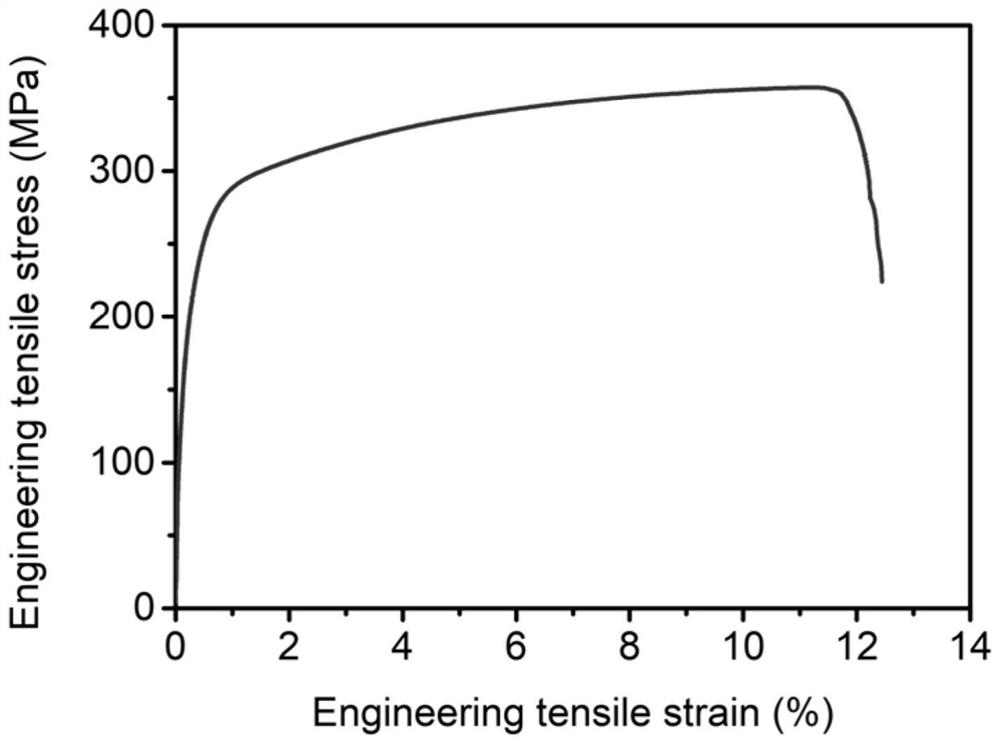

The invention belongs to the technical field of new powder metallurgy materials, and specifically discloses a CuAl-based composite material reinforced by Ti-rich nanoparticles with high strength and toughness, a preparation method and application thereof. The method includes the following steps: (1) directly mixing Cu powder, Al powder and nano-Ti powder through mechanical ball milling, and sintering and forming the obtained mixed powder by using a discharge plasma process; (2) hot rolling of the composite material: the sintered The composite material was post-plastically deformed by hot rolling process, so as to prepare CuAl-based composite material reinforced with Ti-rich nanoparticles with high strength and toughness. The reinforcing phase in the composite material of the present invention is Ti-rich nano particles, which have very good interface bonding and coordinated deformation ability with Cu matrix. The tensile strength of the composite material can reach 600MPa, and at the same time, it has an elongation at break of more than 20%, showing excellent strength and toughness matching, which is significantly better than the Cu-based composite materials currently in industrial application.

Description

A kind of high strength and toughness Ti-rich nanoparticle reinforced CuAl matrix composite material and preparation method thereof with application technical field The invention belongs to the technical field of novel powder metallurgy materials, in particular to a kind of high-strength-tough Ti-rich nano-particle reinforcement CuAl-based composite material, preparation method and application thereof. Background technique In fields such as electric power transportation, microelectronics, high-speed railway and weaponry, pure Cu has excellent thermal conductivity. and electrical conductivity are widely used. However, pure Cu has low strength, usually within 200MPa of tensile strength, making pure Cu devices It is prone to early failure during service, which seriously limits the service life of pure Cu. Therefore, in order to expand the application of Cu materials Therefore, it is urgent to improve the strength of Cu. At present, in order to improve the strength o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C1/04C22C9/00C22C9/01C22F1/08B22F3/105

CPCC22C1/0425C22C9/00C22C9/01B22F3/105C22F1/08B22F2003/1051Y02P10/25

Inventor 郭柏松李卫于振涛

Owner JINAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com