Method for cleaning surface of hollow electrodes in air-tight sealing thyratron

A hollow electrode and thyratron technology is applied in the field of cleaning the surface of hollow electrodes in a hermetically sealed thyratron tube, which can solve problems such as affecting the high-pressure stability performance of the aging and working process, and the surface state cannot meet the requirements of high standard use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

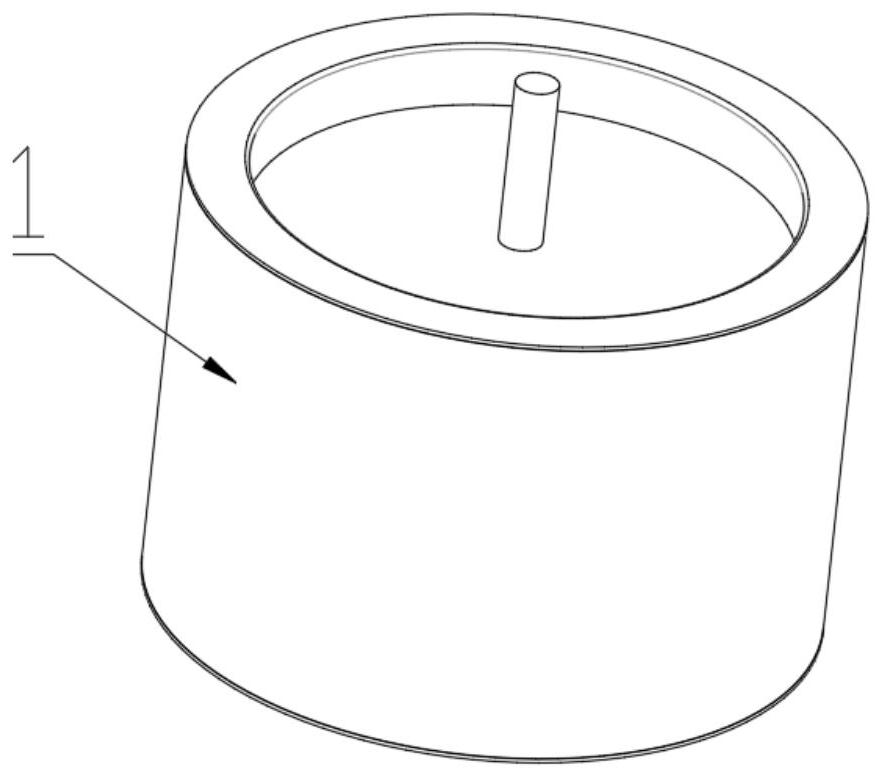

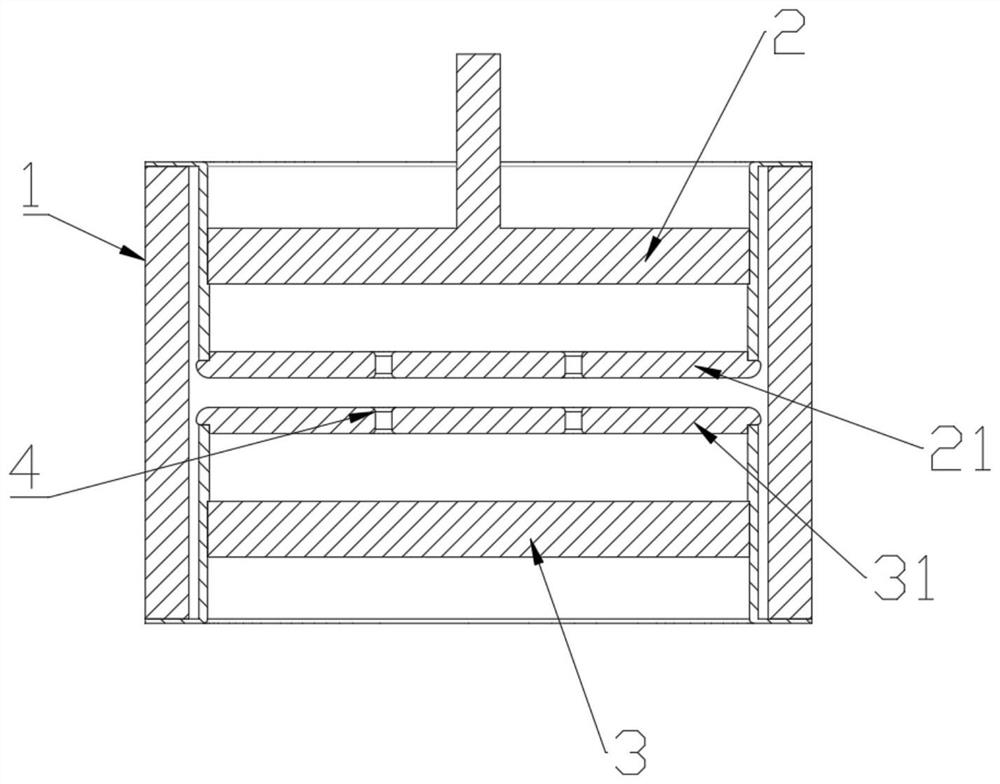

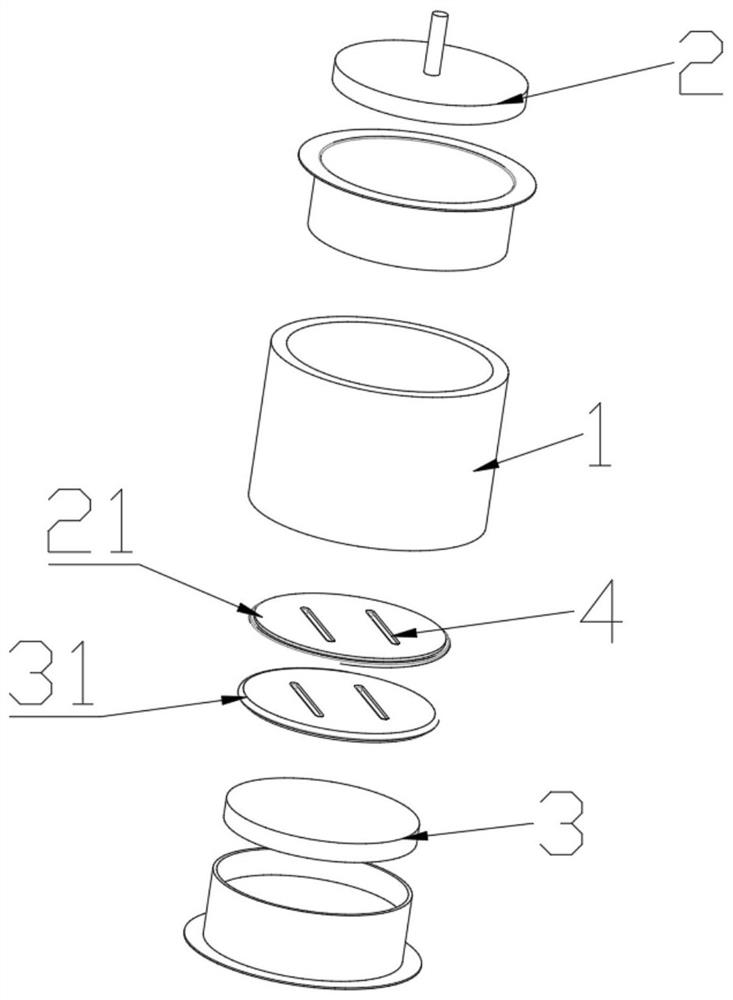

[0031] refer to Figure 1-3 , for the airtight thyratron to be cleaned in the present invention, comprising a ceramic insulating case 1 and two parallel and spaced first hollow electrodes 2 and a second hollow electrode 3 arranged therein, the first hollow electrode 2 of the first hollow electrode An electrode plate 21 and the second electrode plate 31 of the second hollow electrode are arranged oppositely, and the first electrode plate 21 and the second electrode plate 31 are respectively provided with through-hole grooves 4, and the through-hole grooves can be circular, strip-shaped or other shapes.

[0032] A cleaning method for cleaning the surface of the above-mentioned hermetically sealed thyratron hollow electrode, comprising the following steps:

[0033] Step 1: Connect the hermetically sealed thyratron into a device for high-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com