High-precision gyroscope accelerometer floater assembly inertia tensor testing device

An accelerometer and testing device technology, applied in the field of inertial instrument testing, can solve problems such as the inability to calibrate and compensate the inertia tensor of a float assembly, and the inability to accurately calibrate the position of the center of mass of the float assembly, etc., and achieve simple and convenient installation, improved accuracy, and reduced Use the desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

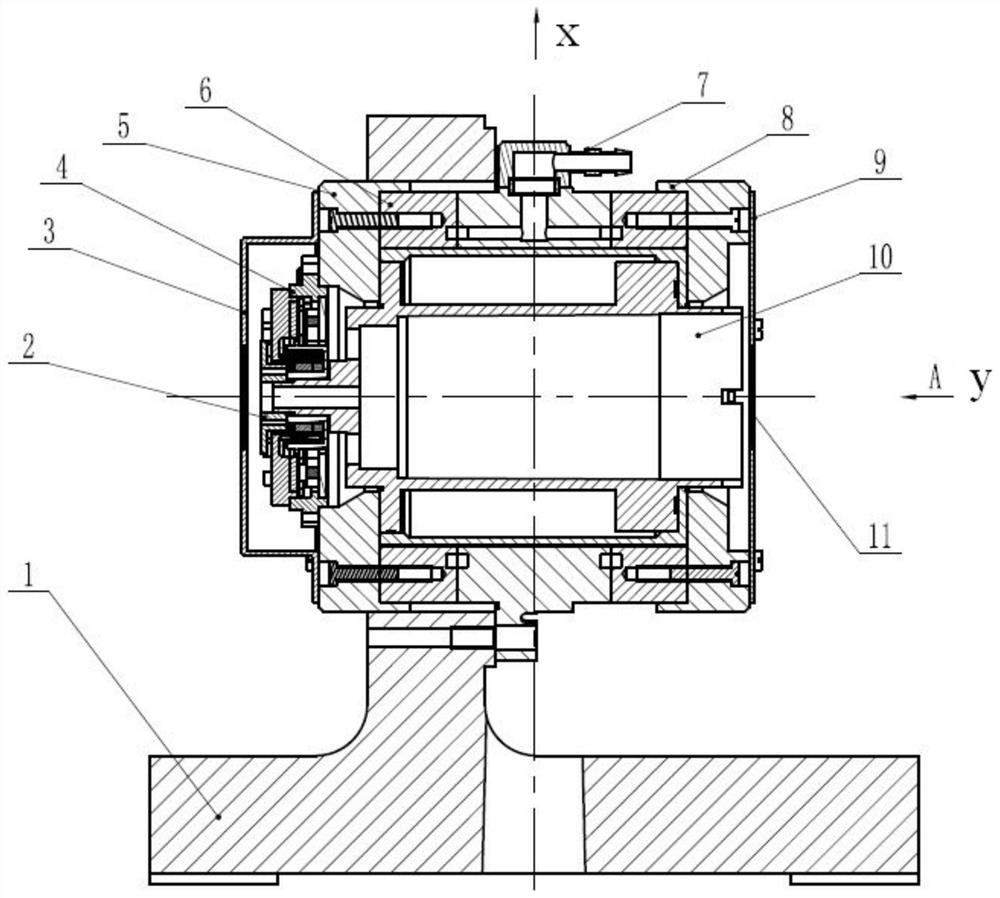

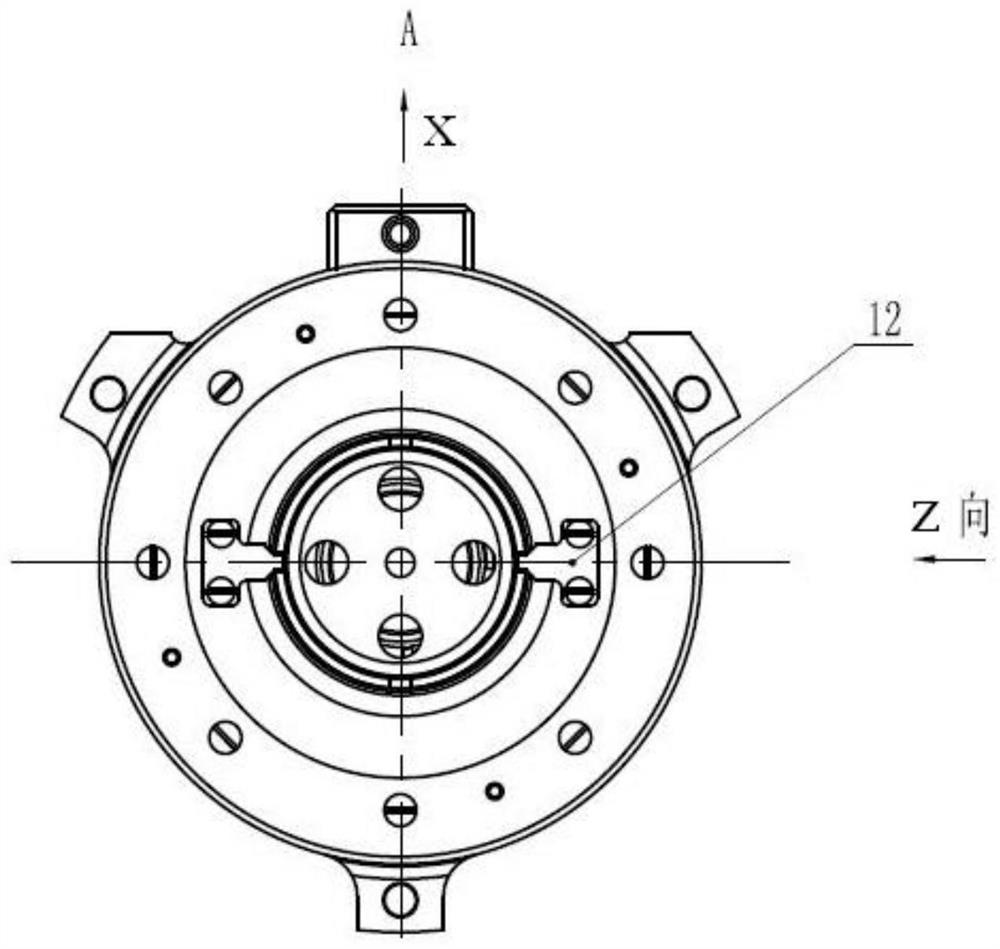

[0046] An inertia tensor testing device for a high-precision gyro accelerometer float assembly, including a mounting plate 1, a balance nut 2, a left cover 3, a combined sensor 4, a left end cover 5, an air bearing sleeve assembly 6, an air nozzle 7, Right end cover 8, right cover 9, rotor body assembly 10, dust screen 11, limit stop nail 12, speed turntable, high-pressure air compression equipment.

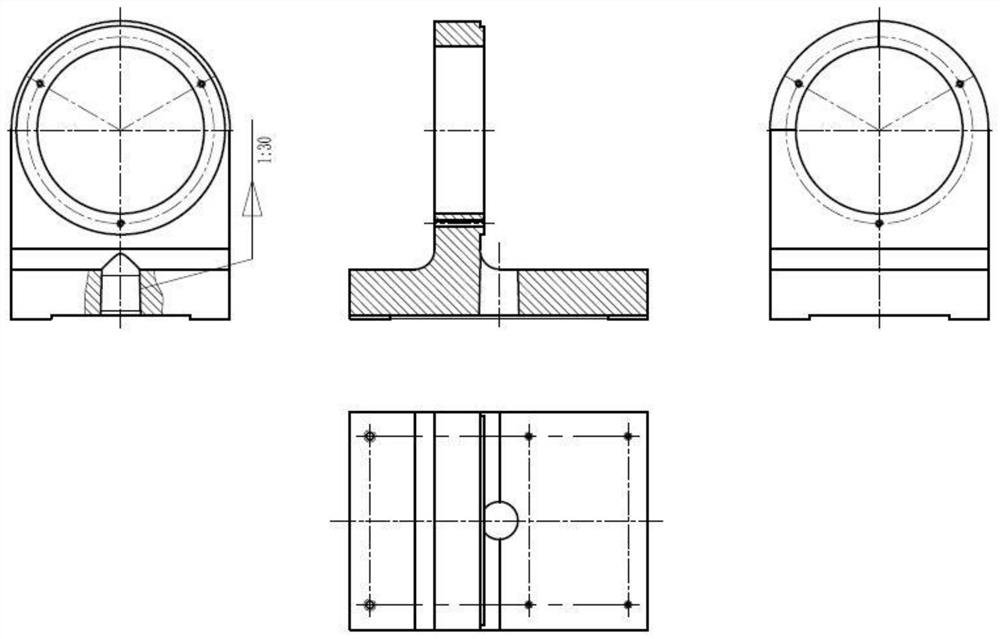

[0047] The mounting plate 1 is a T-shaped base, the right side is the installation reference plane, and there is a through center hole on the reference plane, and there are through thread holes around the through center hole, and they are evenly distributed on concentric circles;

[0048]The through hole at the bottom of the mounting plate has a taper of 1:30 (the large port is downward), and the hole is installed with a round pin with the same taper, so that the center positions between the mounting plate and the speed turntable are coincident, and the installation and operation ...

Embodiment 2

[0065] figure 1 It is an assembly diagram of a gyro accelerometer float assembly inertia tensor test device in an embodiment of the present invention, and the test equipment can be used to calibrate the inertia tensor (non-linear error) of the gyro accelerometer float assembly, which is the Machining and assembly compensation provide the basis. refer to figure 1 and figure 2 , a test device for a gyro accelerometer float assembly provided in this embodiment, including a mounting plate 1, a balance nut 2, a left cover 3, a combined sensor 4, a left end cover 5, an air bearing sleeve assembly 6, and an air nozzle 7 , Right end cover 8, right cover 9, rotor body assembly 10, dust screen 11, limit stop nail 12, speed turntable, compressed air source equipment.

[0066] Such as image 3 As shown, the mounting plate is a T-shaped base, the right side is the installation reference plane, and there is a through central round hole inside the reference plane, and there are 3 small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com