Method for improving measurement precision by using acousto-optic device in optical heterodyne interferometry

A technology of laser heterodyne interference and acousto-optic devices. It is applied in the direction of using optical devices, measuring devices, and measuring ultrasonic/sonic/infrasonic waves. It can solve difficult problems, eliminate or reduce nonlinear errors, reduce interfering light components, The effect of nonlinear error suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

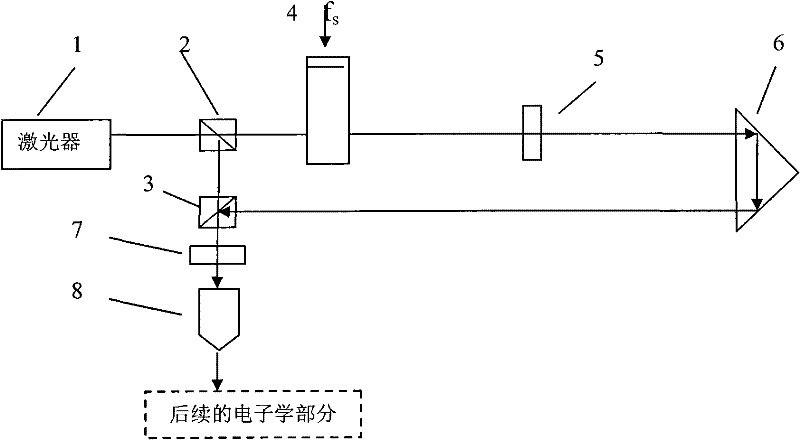

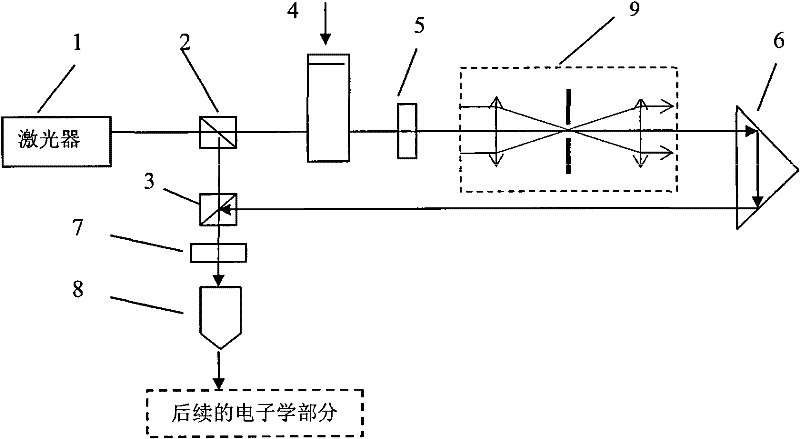

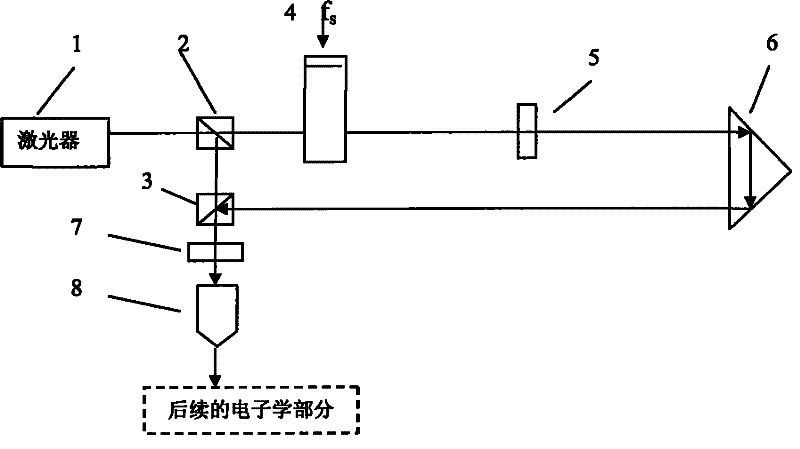

[0022] figure 1 A preferred embodiment of the principle of the optics of the present invention is shown. The laser light emitted by the laser 1 in the figure is divided into two beams by the beam splitter 2, namely the signal beam and the reference beam, wherein the signal light passes through the acousto-optic device 4 to shift the optical frequency of a part of the light to the audio frequency f s The value of the first-order diffracted light is formed, and the acousto-optic device 4 can choose tellurium oxide (TeO 2 ) slow shear wave acousto-optic deflector, and change the polarization direction of the first-order diffracted light by 90°, then pass through the polarizer 5 to eliminate "stray light" with different polarization directions, and then transmit it to the measuring prism 6 After being reflected back, the beam splitter 3 combines it with the reference beam emitted by the beam splitter 2 to form an interference beam. After passing through the polarizer 7, the dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com