Material kitting judgment method based on discrete simulation

A material and complete set technology, applied in the field of material complete set judgment based on discrete simulation, can solve problems such as affecting production efficiency, reducing material turnover efficiency, and changing online time, reducing labor hours for manual statistics and improving inventory turnover. , The effect of accurate material gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

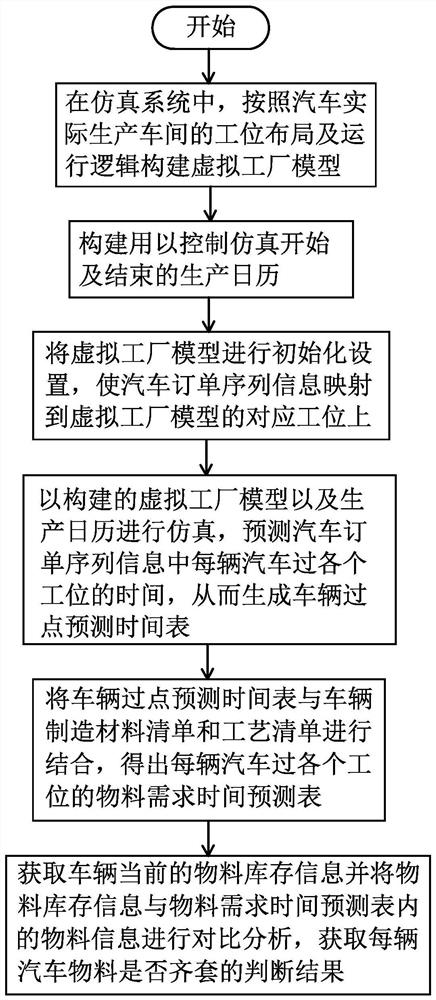

[0046] Such as figure 1 As shown, when using this discrete simulation-based method for judging the complete set of materials to judge the complete set of materials, first construct a virtual factory model in the background of the simulation system according to the factory layout and operation logic, to ensure that the station layout, buffer area settings, and scheduling rules are consistent with the actual The logic in the factory is consistent, and the buffer area is set between the two line bodies, which is used to simulate the stoppage of the front and rear line bodies so as not to affect the continued production of other lines; the scheduling rule refers to the relationship between the two workshops Because of the diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com