Preparation method of red rose extract, red rose extract and food

A technology of rose flower and extract, which is applied in the field of extraction, can solve the problems of high preparation cost and high dosage of citric acid, and achieve the effects of low dosage, reduced preparation cost and low sour taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

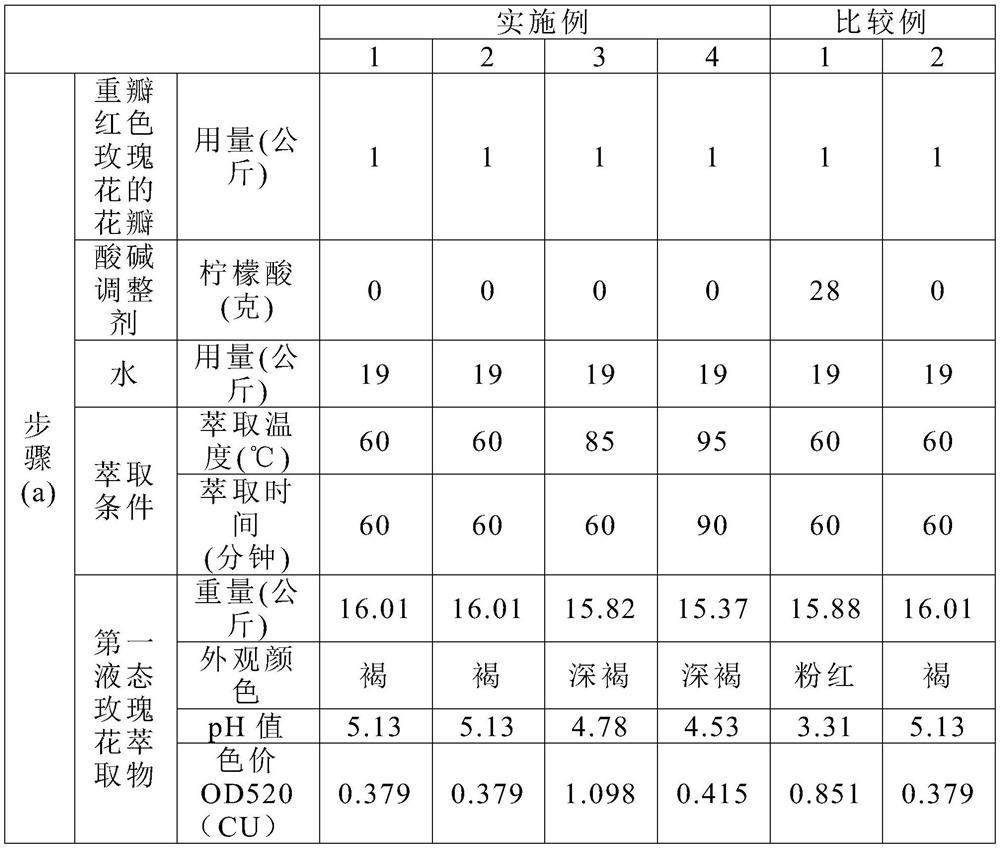

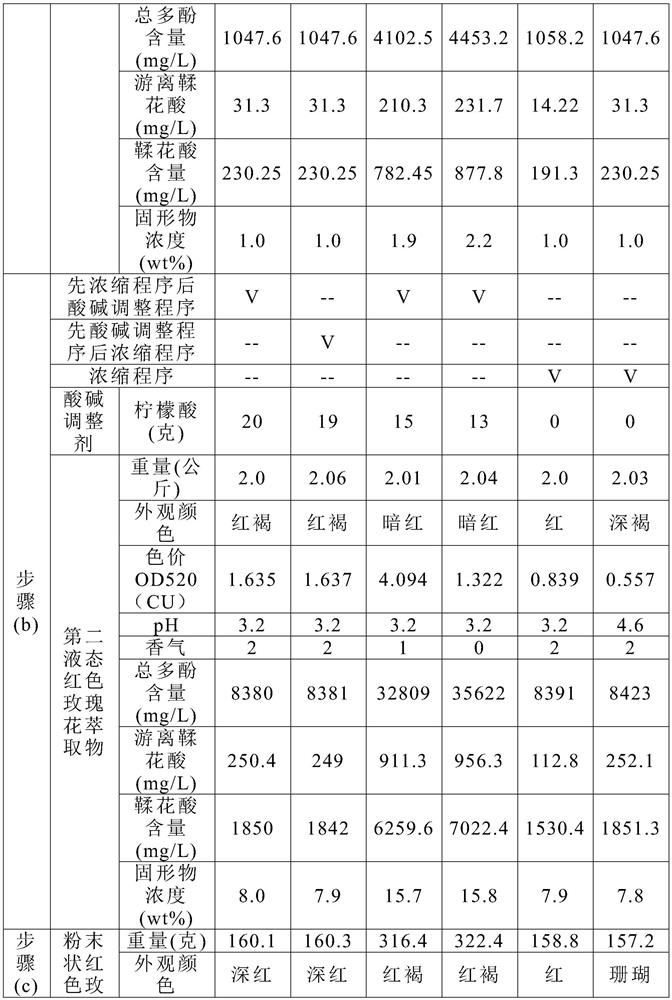

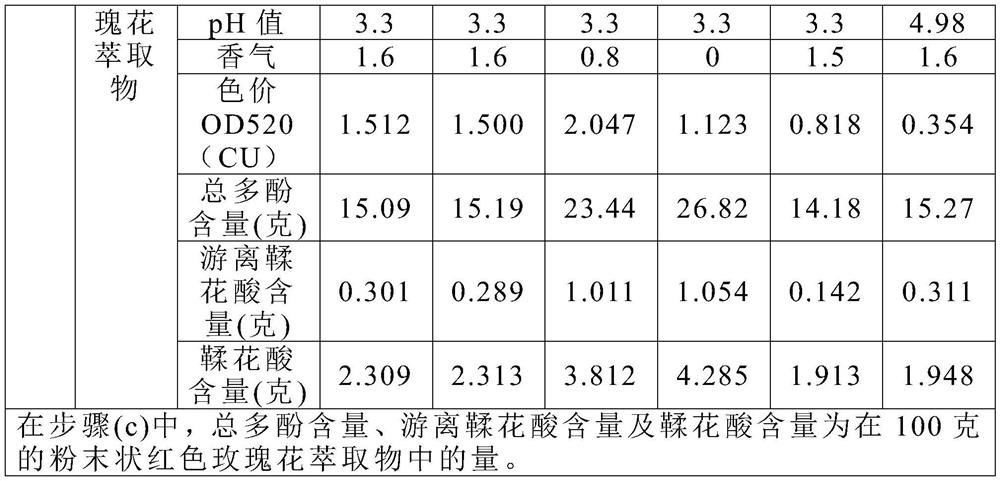

[0020] The preparation method of the red rose extract of the present invention comprises the following steps: Step (a), sequentially extracting and separating the mixture to form a first liquid rose extract, the mixture comprising red rose and water; and Step (b), adjusting the first liquid rose extract to form a second liquid red rose extract with a pH value of less than 4.6 and including red pigment components, ellagic acid and polyphenol components, The adjustment process includes a concentration procedure and an acid-base adjustment procedure using an acid-base regulator.

[0021] The content of the present invention will be described in detail below.

[0022]

[0023] The red roses are for example but not limited to double red roses. The red roses are fresh red roses or dried red roses. The red roses used can be whole buds or petals. In some embodiments of the present invention, the red roses are dried red roses. The dried red roses are not particularly limited, and...

Embodiment 1

[0037] Step (a): 1 kg of petals (water content is 13.8wt%) of the double-petaled red rose that has been dried are mixed with 19 kg of 65°C hot water to form a mixture, and then, the temperature is 60°C Under the condition of using a stirrer with a rotation speed set at 60rpm, the mixed solution was stirred and extracted for 60 minutes, and then the temperature was lowered to 50°C, and under the conditions of the temperature, a sieve with a mesh number of 300 was used to The separation process was carried out to obtain 16.01 kg of the first liquid rose extract, and the solid concentration in the first liquid rose extract was 1.0 wt%.

[0038] Step (b): Use a vacuum concentrator to concentrate the first liquid rose extract at a temperature of 55°C to the remaining 2 kg, then lower the temperature to 45°C, and then add 20 gram of citric acid, the pH value was adjusted to 3.2 to obtain 2.0 kg of the second liquid red rose extract, and the solid concentration in the second liquid r...

Embodiment 2

[0041]The embodiment 2 is basically carried out with the same steps as the embodiment 1, the main difference lies in: step (b). In step (b), 19 grams of citric acid was added to the first liquid rose extract to adjust the pH to 3.2, and then, using a vacuum concentrator at a temperature of 55°C Concentrate and concentrate to the remaining 2.06 kg, then lower the temperature to 45° C. to obtain a second liquid red rose extract, the solid concentration in the second liquid rose extract is 7.8 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com